A composite material sound-absorbing and noise-reducing lining and its preparation method

A technology of composite material and composite material layer, which is applied in the field of composite material noise reduction and noise reduction lining and its preparation, can solve the unfavorable noise reduction and noise reduction lining structure weight reduction and safety performance requirements, impact resistance, chemical corrosion resistance and fatigue resistance Insufficient performance, debonding of the panel and the honeycomb core, etc., to achieve excellent noise reduction effect, excellent sound insulation, anti-acoustic vibration, and good sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

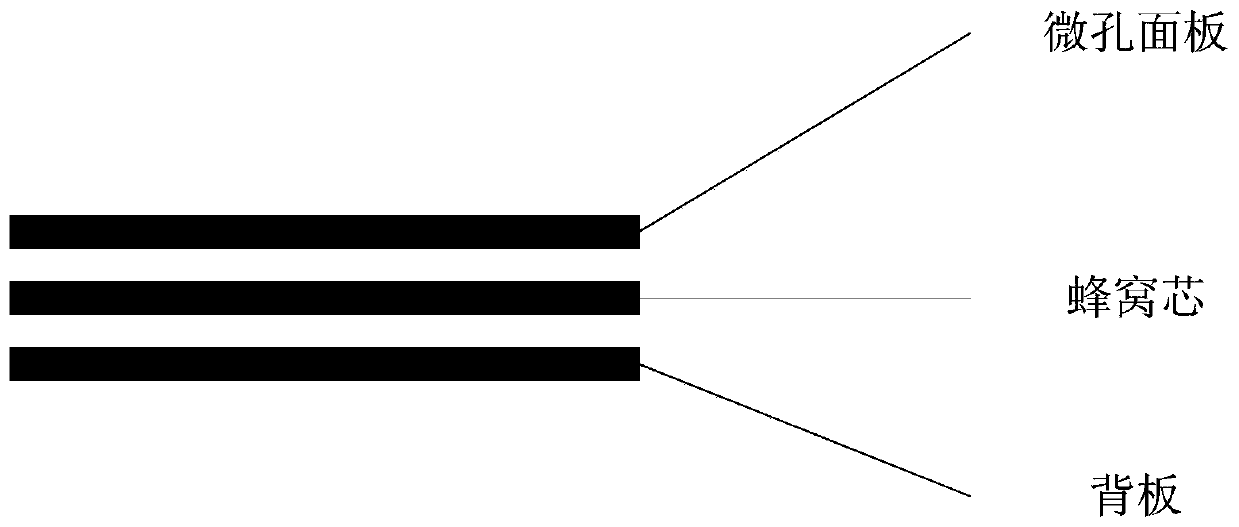

[0092] Such as figure 1 As shown, the acoustic lining includes a microporous panel, a honeycomb core and a backboard; the honeycomb core is located between the microporous panel and the backboard;

[0093]The face plate and the back plate are made of aramid fiber fabric medium-temperature curing epoxy resin hot-melt prepreg, and the adhesive film is 130°C medium-temperature curing film.

[0094] After the automatic blanking machine is used for blanking according to the layup and size requirements, the multi-layer prepreg is laid layer by layer on the forming female mold of the panel and the back panel according to the designed layup angle, and the composite prepreg stack is obtained. layer, and then use the vacuum bag / autoclave molding method to cure. When curing, the vacuum gauge pressure is not greater than -0.097MPa, the heating rate is 30°C / h, and the pressure is increased to 0.6MPa when the temperature rises to 130°C. After 30 minutes of heat preservation, continue When ...

Embodiment 2

[0103] The panel and the back panel are made of glass fiber fabric medium-temperature curing hot-melt prepreg, and the adhesive film is made of medium-temperature curing film at 130°C.

[0104] After the automatic blanking machine is used to blank the material according to the lay-up and size requirements, the multi-layer prepreg is laid on the molding mold layer by layer according to the designed lay-up angle to make a composite material prepreg laminate, and then use a vacuum bag / Autoclave molding method for curing. When curing, the vacuum gauge pressure is not greater than -0.097MPa, the heating rate is 20°C-40°C / h, when the temperature rises to 130°C, pressurize to 0.6MPa, and continue to heat up after 30min of heat preservation. When it reaches 130±5°C, keep it warm for 4 hours, and then cool down to below 60°C at a cooling rate of 30°C-50°C / h to complete the curing. After cooling down to room temperature, the panel and back panel are demoulded, and the rough edge of the ...

Embodiment 3

[0113] The face plate and the back plate use aramid fiber fabric high-temperature curing hot-melt prepreg, and the adhesive film adopts a high-temperature curing adhesive film at 180°C.

[0114] After the automatic blanking machine is used to blank the material according to the lay-up and size requirements, the multi-layer prepreg is laid on the molding mold layer by layer according to the designed lay-up angle to make a composite material prepreg laminate, and then use a vacuum bag / Autoclave molding method for curing. When curing, the vacuum gauge pressure is not greater than -0.097MPa, the heating rate is 20°C-40°C / h, when the temperature rises to 180°C, pressurize to 0.6MPa, and continue to heat up after 30min of heat preservation. When it reaches 180±5°C, keep it warm for 4 hours, and then cool down to below 60°C at a cooling rate of 30°C-50°C / h to complete the curing. After dropping to room temperature, the panel and back panel are demoulded, and the rough edge of the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com