Preparation method of antibacterial polyester fiber

A technology of polyester fiber and polyester melt, which is applied in the field of preparation of antibacterial polyester fiber, can solve problems such as soft luster, poor dyeability, and difficulty in dyeing, and achieve good wearing comfort, simple preparation process, and UV resistance The effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

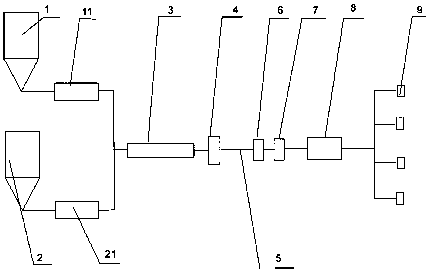

[0015] Such as figure 1 As shown, the preparation method of a kind of antibacterial polyester fiber described in the present embodiment is as follows: its components are 80 parts by mass parts of PET polyester chip, 20 parts of superfine bamboo cellulose micropowder. The slices in the PET polyester chip silo 1 are dried by the dryer and enter the feeding hopper 11, mixed with the ultrafine bamboo cellulose powder in the feeding hopper 21, and transported to the temperature of 265°C, 270°C, 280°C, 280°C, 280°C The screw extruder 3 performs melt extrusion, and the melted and mixed uniform raw materials pass through the filter 4, and the uniformly mixed melt is pressurized by the booster pump 6 and cooled by the melt cooler 7 through the conveying pipeline 5, and then the distributing valve The flow is diverted to each spinning box 8; metered by a metering pump, the polyester melt is injected into the spinning assembly, filtered, extruded, and then cooled by a ring blower to obta...

Embodiment 2

[0017] Such as figure 1 As shown, the preparation method of a kind of antibacterial polyester fiber described in the present embodiment is as follows: its components are 75 parts by mass parts of PET polyester chip, 25 parts of superfine bamboo cellulose micropowder. The slices in the PET polyester chip silo 1 are dried by the dryer and enter the feeding hopper 11, mixed with the ultra-fine bamboo cellulose powder in the feeding hopper 21, and transported to a temperature of 264°C, 269°C, 278°C, 278°C, 278°C The screw extruder 3 performs melt extrusion. The uniformly melted and mixed raw materials pass through the filter 4, and the uniformly mixed melt is pressurized by the booster pump 6 and cooled by the melt cooler 7 through the conveying pipeline 5, and then distributed to each spinning box 8 by the distribution valve; The metering pump is metered, the polyester melt is injected into the spinning assembly, filtered, extruded, and then cooled by the surrounding air to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com