Special evaporator device for waste acid

An evaporator and waste acid technology, applied in the direction of heating water/sewage treatment, etc., can solve the problems of environmental damage, inability to directly reuse, increase the cost of waste water treatment, etc., and achieve the characteristics of not easy to coke, good energy saving and environmental protection, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

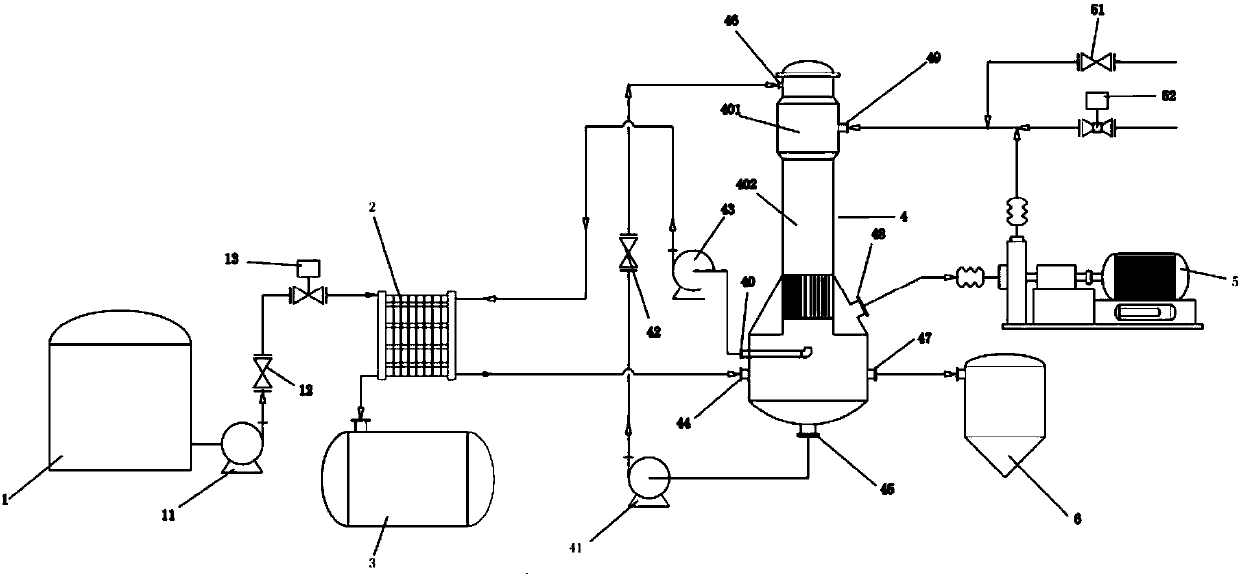

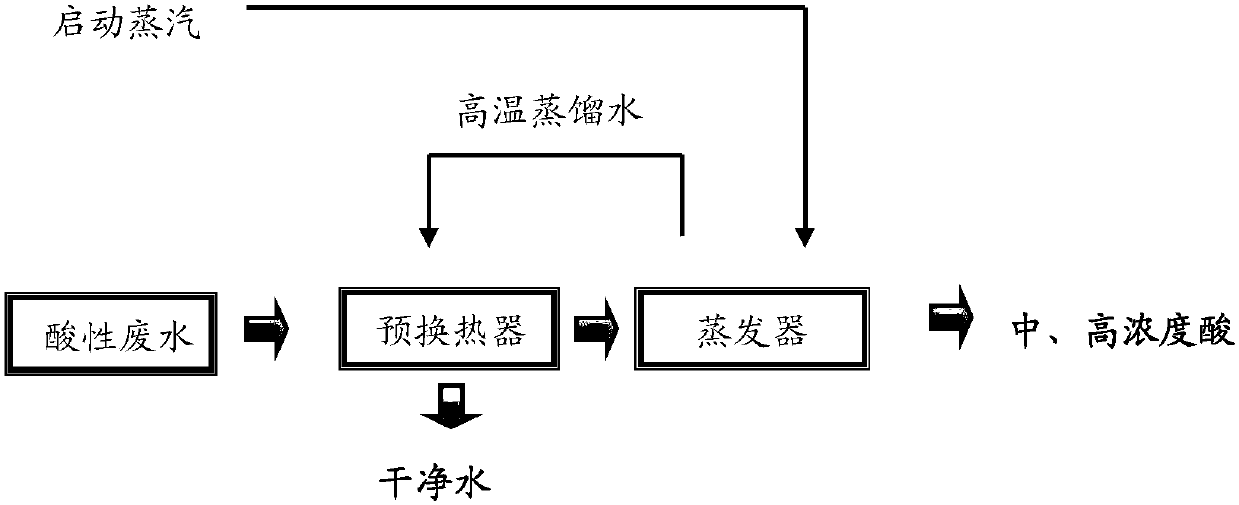

Method used

Image

Examples

Embodiment

[0032] Taking sulfuric acid wastewater from a certain enterprise as an example, its sulfuric acid content is 14%, and the specific gravity of wastewater is about 1.09g / ml. The special evaporator device for waste acid is made of nickel-based corrosion-resistant alloy. Nickel-based alloy refers to a type of alloy with comprehensive properties such as high strength and certain oxidation and corrosion resistance at a high temperature of 650-1000 °C. The main alloying elements are copper, chromium and molybdenum, which have good comprehensive properties and can resist various acid corrosion and stress corrosion. The sulfuric acid wastewater in this enterprise enters the special evaporator device for waste acid after preliminary pretreatment. The material input and output of the new waste acid special evaporator are shown in Table 1:

[0033]

[0034]

[0035] Table 1

[0036] The material enters the special evaporator device for waste acid after passing through the pre-heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com