Semi-continuous extraction or reextraction method for heat-sensitive and easily emulsifying organic phase

An organic phase, semi-continuous technology, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of accelerated denaturation speed of extractant, fast reaction speed, large consumption of reagents, etc., to avoid long-term high temperature denaturation, avoid impact, and increase production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

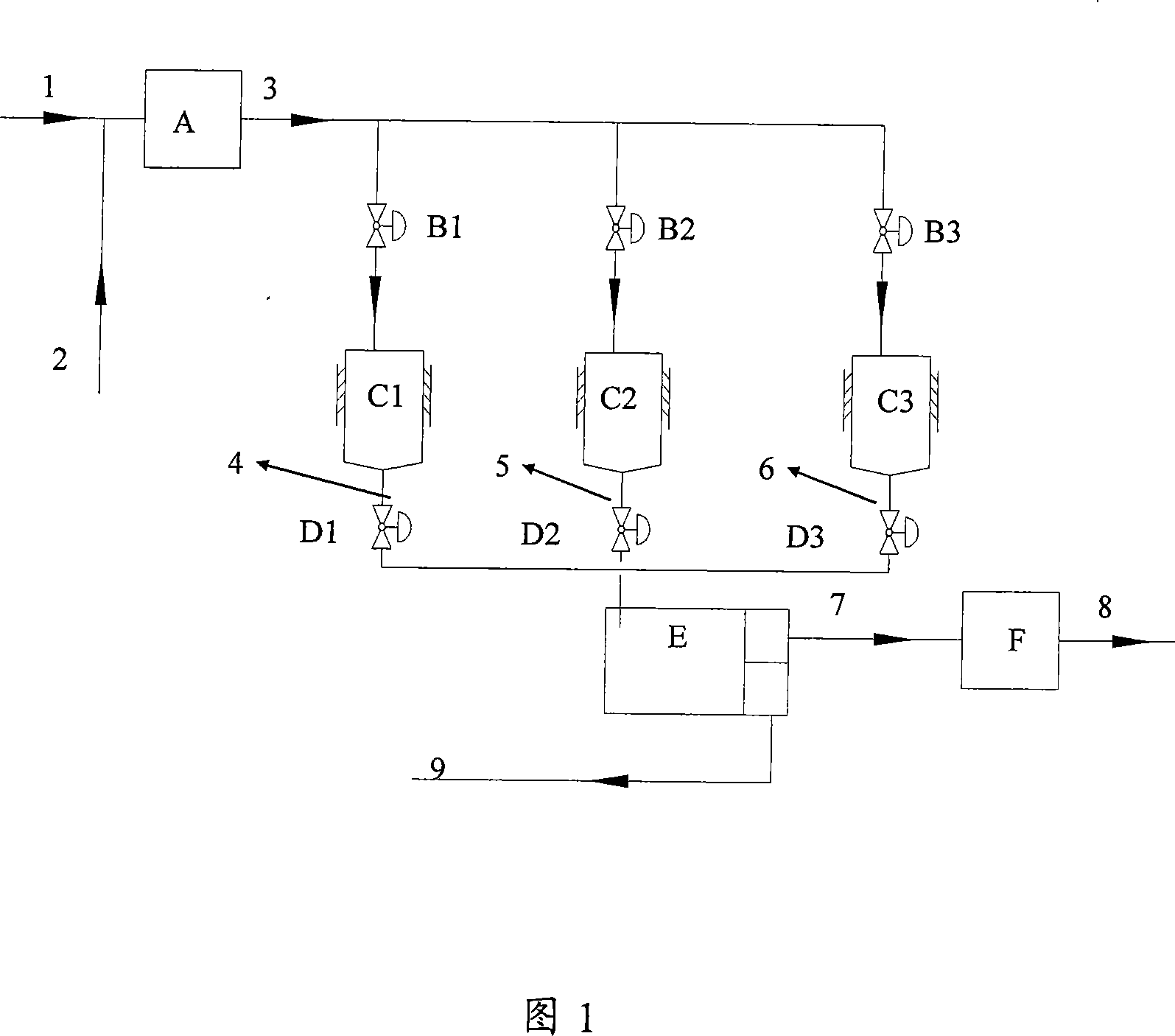

[0012] Attached below figure 1 Illustrates a semi-continuous extraction or stripping process for processing heat-sensitive, easily emulsified organic phases:

[0013] First, the extractant 1 for extraction and the aqueous solution 2 to be treated, or the loaded organic phase 1 and stripping agent 2 for stripping are respectively metered and then continuously transported to the preheater A and heated up to the temperature required by the process Finally, the high-temperature oil-water mixture 3 is used for extraction or stripping;

[0014] Secondly, open the stirring system of the extraction or stripping reactor C1 inlet automatic adjustment valve B1 and C1-C3, close the C1 outlet automatic adjustment valve D1, close the C2, C3 import and export automatic adjustment valve B2, B3, D2, D3, let 3 Enter C1, and perform extraction or stripping in C1;

[0015] After a certain period of time, open the C2 inlet automatic adjustment valve B2, close the C1 inlet automatic adjustment va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com