A kind of preparation method of smokeless black betel nut

A production method and betel nut technology, applied in the field of food processing, can solve the problems of big difference in taste of betel lang black fruit, non-compliance with detection standards, infiltration of blackened parts, etc., and achieve the effects of soft taste, easy to remove pits, and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

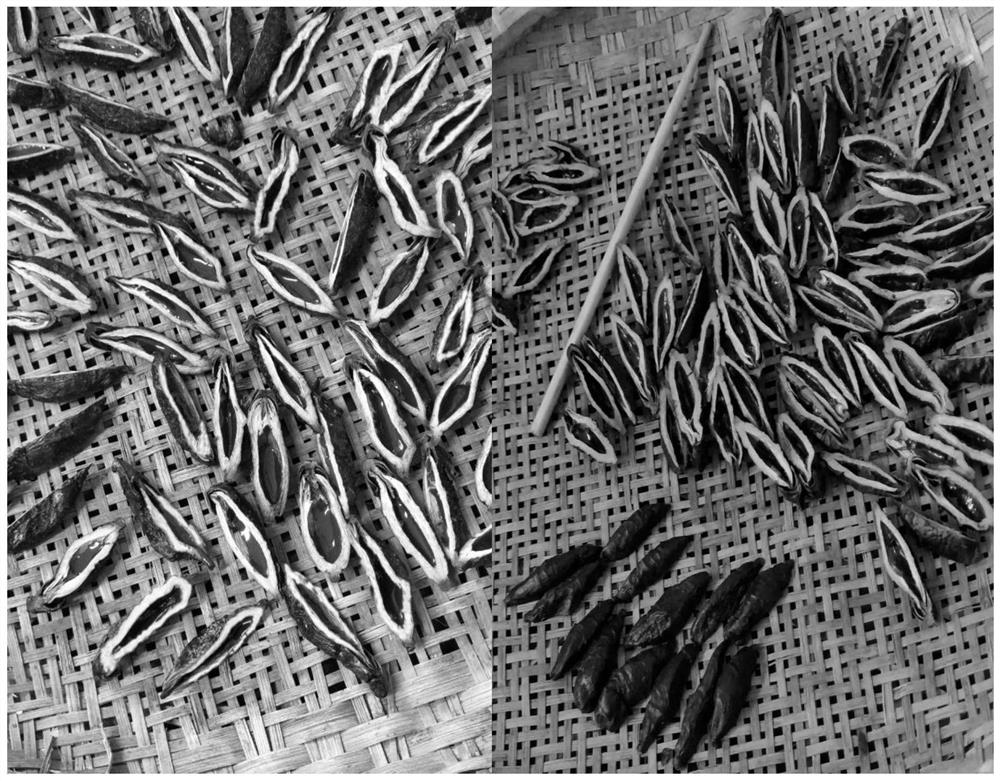

Image

Examples

Embodiment 1

[0039] A preparation method of smokeless black fruit betel nut, comprising the following method steps:

[0040] Step 1. Seed selection: select green fruit betel nut with good quality, full particles and fine and deep mesh grooves for use;

[0041] Step 2, microwave pretreatment: use microwave heating equipment to carry out microwave heating treatment on green fruit betel nut, microwave power 800W, microwave time 3min, put the processed green fruit betel nut into food-grade alkaline water with a concentration of 5% for 5min, and use clear water to soak it. Rinse the surface of betel nut;

[0042] Step 3, boil the seeds: put the green fruit betel nut processed in step 2 into the seed cooking machine, add water and add the food-grade sodium sulfite of 0.045% of the total amount of betel nut to boil the seeds, the temperature is 98°C, and the time is 20min;

[0043] Step 4. Corrosion and steam explosion treatment: take out the betel nut processed in step 3, drain and put it into ...

Embodiment 2

[0055] A preparation method of smokeless black fruit betel nut, comprising the following method steps:

[0056] Step 1. Seed selection: select green fruit betel nut with good quality, full particles and fine and deep reticulated grooves for use;

[0057] Step 2, microwave pretreatment: use microwave heating equipment to carry out microwave heating treatment on green fruit betel nut, microwave power 1200W, microwave time 5min, put the processed green fruit betel nut into food-grade alkaline water with a concentration of 8% and soak for 10min, use clear water to soak it. Rinse the surface of betel nut;

[0058] Step 3, boil the seeds: put the green fruit betel nut processed in step 2 into the seed cooking machine, add water and add food-grade sodium sulfite of 0.045% of the total amount of betel nut to boil the seeds, the temperature is 100 ° C, and the time is 30 min;

[0059] Step 4. Corrosion and steam explosion treatment: take out the betel nut treated in step 3, drain and ...

Embodiment 3

[0071] A preparation method of smokeless black fruit betel nut, comprising the following method steps:

[0072] Step 1. Seed selection: select green fruit betel nut with good quality, full particles and fine and deep reticulated grooves for use;

[0073] Step 2, microwave pretreatment: use microwave heating equipment to carry out microwave heating treatment on green fruit betel nut, microwave power 900W, microwave time 4min, put the processed green fruit betel nut into food-grade alkaline water with a concentration of 10% for 8min, and rinse with water. Rinse the surface of betel nut;

[0074] Step 3, boil the seeds: put the green fruit betel nut processed in step 2 into the seed cooking machine, add water and add the food-grade sodium sulfite of 0.045% of the total amount of betel nut to boil the seeds, the temperature is 99°C, and the time is 26min;

[0075] Step 4. Corrosion and steam explosion treatment: take out the betel nut treated in step 3, drain and put it into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com