A kind of preparation method of barium sodium titanate composite negative electrode material for lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing the energy density of the whole battery, low lithium ion diffusion rate, low theoretical capacity, etc., and achieve excellent rate performance, dispersion The effect of good performance, stability and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

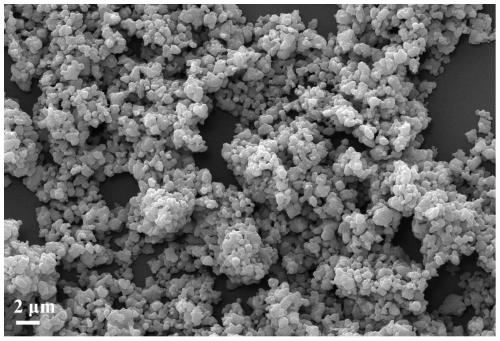

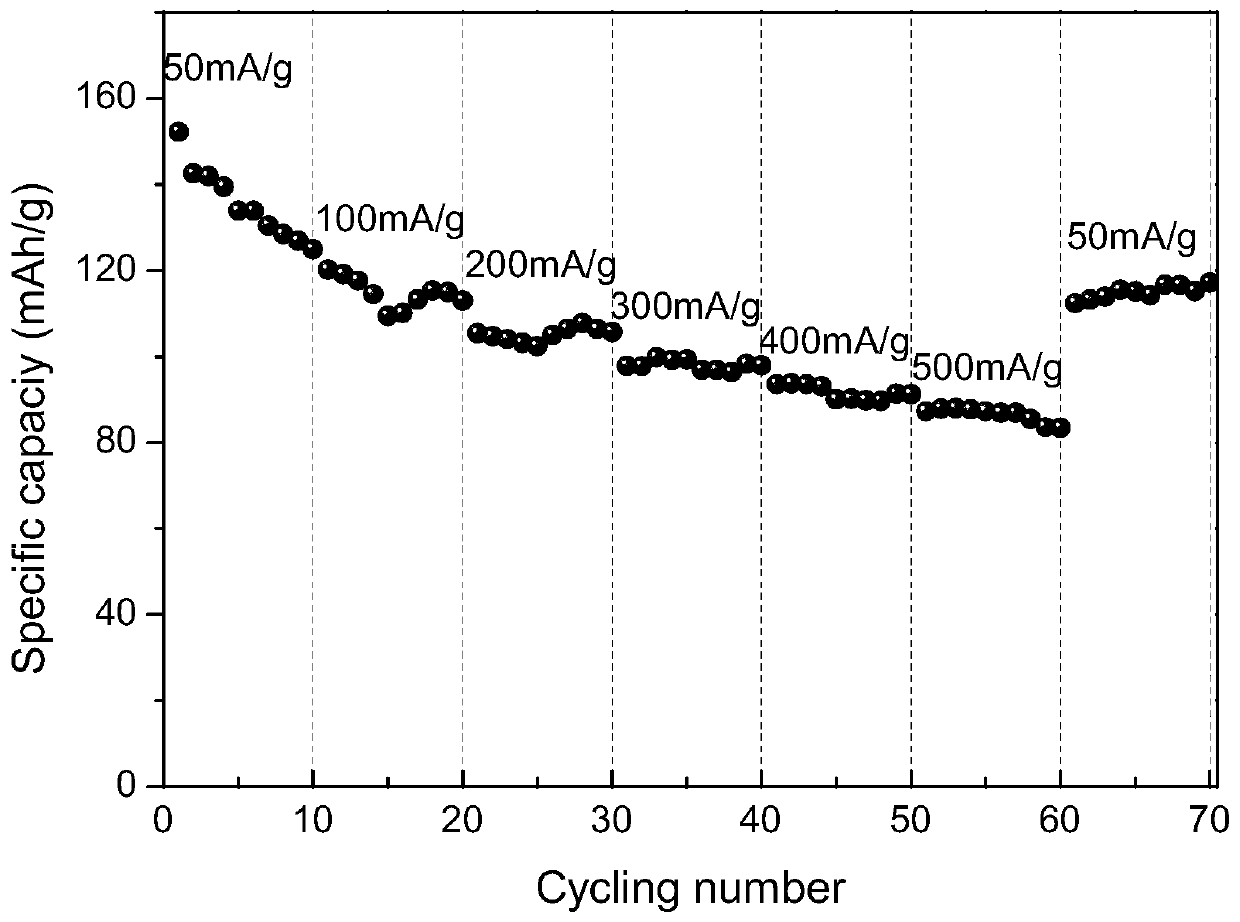

[0020] Dissolve 0.02mol sodium nitrate and 0.01mol barium nitrate in 300mL ethanol aqueous solution, add citric acid, the ratio of citric acid to metal cation is 3.5:1, stir for 3h, and record it as solution A; 4 Dissolved in alcohol solution, stirred for 2h, recorded as solution B. The solutions A and B were quickly mixed and vigorously stirred, and the temperature was raised to 80°C. After the liquid was evaporated to dryness, it was placed in a vacuum drying oven for 12 hours at 100°C for vacuum drying. Then put the precursor in a muffle furnace for pre-calcination at 450°C for 6 hours, cool to room temperature, mill in a ball mill for 4 hours, sieve, put it into a muffle furnace and burn at 1000°C for 12 hours, cool to room temperature, and ball mill 24h, the lithium-ion battery negative electrode material BaNa 2 Ti 6 o 14 Material. Take 1g of the resulting BaNa 2 Ti 6 o 14 Put the material into a clean beaker, add 100mg of sodium dodecylsulfonate, add 400mL of deio...

Embodiment 2

[0022] Dissolve 0.02mol sodium nitrate and 0.01mol barium nitrate in 300mL ethanol aqueous solution, add citric acid, the ratio of citric acid to metal cation is 3:1, stir for 2h, record as solution A; 4 Dissolved in alcohol solution, stirred for 1h, recorded as solution B. The solutions A and B were quickly mixed and vigorously stirred, and the temperature was raised to 80°C. After the liquid was evaporated to dryness, it was placed in a vacuum drying oven at 90°C for 12 hours in vacuum. Then put the precursor in a muffle furnace at 400°C for 4 hours, cool to room temperature, ball mill in a ball mill for 3 hours, sieve, put it in a muffle furnace and burn at 900°C for 10 hours, cool to room temperature, and ball mill 24h, the lithium-ion battery negative electrode material BaNa 2 Ti 6 o 14 Material. Take 1g of the resulting BaNa 2 Ti 6 o 14 Put the material into a clean beaker, add 100mg of sodium dodecylsulfonate, then add 400mL of deionized water, sonicate for 10min...

Embodiment 3

[0024] Dissolve 0.02mol sodium nitrate and 0.01mol barium nitrate in 300mL ethanol aqueous solution, add citric acid, the ratio of citric acid to metal cation is 4:1, stir for 3h, record as solution A; 4 Dissolved in alcohol solution, stirred for 2h, recorded as solution B. The solutions A and B were quickly mixed and vigorously stirred, and the temperature was raised to 80°C. After the liquid was evaporated to dryness, it was placed in a vacuum drying oven at 120°C for vacuum drying for 12 hours. Then put the precursor in a muffle furnace at 600°C for 6 hours, cool to room temperature, mill in a ball mill for 4 hours, sieve, put it in a muffle furnace and burn at 1100°C for 15 hours, cool to room temperature, and ball mill 24h, the lithium-ion battery negative electrode material BaNa 2 Ti 6 o 14 Material. Take 1g of the resulting BaNa 2 Ti 6 o 14 Put the material into a clean beaker, add 100mg of sodium dodecylsulfonate, then add 400mL of deionized water, sonicate for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com