Polyether-ether-ketone high-voltage flexible DC transmission optical fiber composite extruded cable

A flexible direct current transmission, polyether ether ketone technology, applied in the direction of insulated cables, communication cables, flexible cables, etc., can solve the problems of low carrier mobility, catalyst residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1. Preparation of modified potassium hexatitanate whiskers:

[0031] Add 1 to 3 kg of titanate coupling agent—pyrophosphate type monoalkoxy titanate TMC-114 or KR-38S into a mixed solvent of 10 L of water and 20 L of ethanol. After stirring for 60 min, add 100 kg of potassium hexatitanate whiskers with a diameter of 0.2-1.5 μm and a length of 10-50 μm into the above titanate coupling agent solution, ultrasonically disperse for 1-2 h, and then remove the Solvent ethanol and water to obtain 100 kg of surface-modified potassium hexatitanate whiskers.

[0032] 2. Preparation of thermally conductive insulating polyetheretherketone cable material:

[0033] 1. Preparation of modified nano-inorganic thermally conductive materials:

[0034] Method 1: Preparation of modified nano silicon nitride:

[0035] Add 1.0 kg of silane coupling agent KH550 into 10 L of water and 20 L of ethanol mixed solvent, stir for 30 min, then add 100 kg of nano-silicon nitride into the silane coupl...

example 1

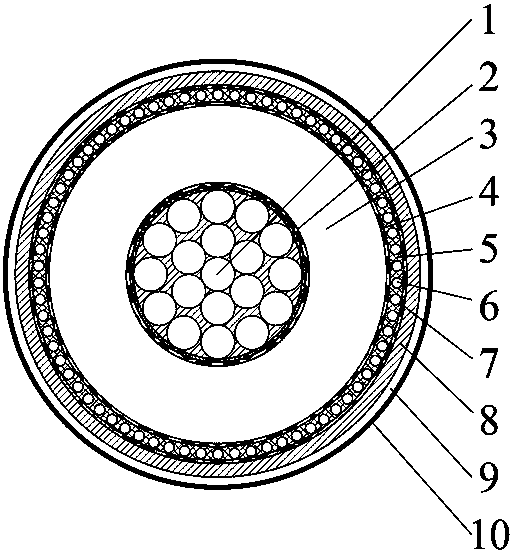

[0086] Example 1. Production of cables with rated voltage ±160 kV:

[0087] (1) At a cross-sectional area of 500 mm 2 The tightly pressed circular copper conductor is wrapped with a semi-conductive nylon wrapping tape.

[0088] (2) Take the semi-conductive polyetheretherketone cable material, and form a conductor shielding layer 2 outside the wrapping tape through an extrusion process, with a thickness of 1.3 mm.

[0089] (3) Take thermally conductive and insulating polyetheretherketone cable material, and form an insulating layer 3 outside the conductor shielding layer 2 through extrusion process, with a thickness of 12.5 mm.

[0090] (4) Take the semiconductive polyether ether ketone cable material, and form an insulating shielding layer 4 outside the insulating layer 3 through an extrusion process, with a thickness of 1.0 mm.

[0091] (5) Wrap the optical fiber 6 in a stainless steel tube to make an optical fiber protected by a stainless steel tube in which the optical ...

example 2

[0097] Example 2. Production of cables with rated voltage ±220 kV:

[0098] (1) In a cross-sectional area of 1000 mm 2 The tightly pressed round high-purity aluminum conductor is wrapped with a semi-conductive nylon wrapping tape.

[0099] (2) Take the semi-conductive polyetheretherketone cable material, and form a conductor shielding layer 2 outside the wrapping tape through an extrusion process, with a thickness of 2.0 mm.

[0100] (3) Take thermally conductive and insulating polyetheretherketone cable material, and form an insulating layer 3 outside the conductor shielding layer 2 through an extrusion process, with a thickness of 25.0 mm.

[0101] (4) Take the semi-conductive polyetheretherketone cable material, and form an insulating shielding layer 4 outside the insulating layer 3 through an extrusion process, with a thickness of 1.3 mm.

[0102] (5) Wrap the optical fiber 6 in a stainless steel tube to make an optical fiber protected by a stainless steel tube in whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com