Preparation method of low-temperature-resistant TPU hot melt adhesive membrane

A technology of hot-melt adhesive film and low temperature resistance, which is applied in the direction of heat-activated film/sheet, film/sheet-shaped adhesive, adhesive, etc., and can solve problems such as poor bonding strength, high melting point, stretching or fracture, Achieve strong surface adsorption and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

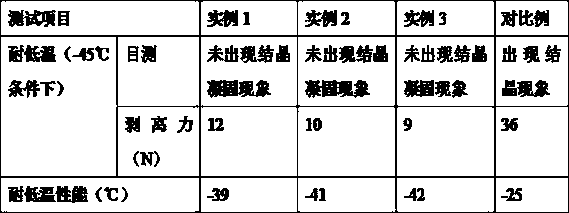

example 1

[0024] Put 60g of rosin into a four-necked flask equipped with a condenser, a stirrer, and a dropping funnel, pass nitrogen to the four-necked flask to drive away the air, heat up to 150°C, start the agitator, and stir at a speed of 400r / min. After all melted, add 35g of rosin, add dropwise 30mL of maleic anhydride to the four-neck flask with a dropping funnel at a dropping rate of 3mL / min while stirring. Diolefination product: add 40mL glycerin to the above-mentioned dienylation product, heat the above-mentioned four-neck flask to 270°C, keep the temperature for 7 hours, cool down to room temperature naturally, and discharge the material to obtain the esterification product, and vacuumize the esterification product , control the vacuum degree to be 0.02MPa, take out the small molecule product, obtain the esterified product of purification, namely modified rosin; Alcohol, 10 parts of stannous octoate, and 20 parts of modified rosin are placed in a three-necked flask with a ven...

example 2

[0026] Add 63g of rosin into a four-necked flask equipped with a condenser, a stirrer, and a dropping funnel, pass nitrogen to the four-necked flask to drive away the air, heat up to 155°C, start the agitator, and stir at a speed of 500r / min. After all melted, add 38g of rosin, and add 33mL of maleic anhydride dropwise to the four-neck flask with a dropping funnel at a dropping rate of 3mL / min while stirring. Obtain the dienylation product; add 43mL glycerin to the above-mentioned dienylation product, heat the above-mentioned four-necked flask to 275°C, keep it warm for 7.5h, cool down to room temperature naturally, and discharge the material to obtain the esterification product, and the esterification product Vacuumize, control the vacuum degree to be 0.03MPa, take out the small molecular product, obtain the esterification product of purification and be modified rosin; By weight, 38 parts of polybutylene adipate diol, 23 parts of polyoxygen Propylene glycol, 11 parts of stannou...

example 3

[0028] Add 65g of rosin into a four-necked flask equipped with a condenser, a stirrer, and a dropping funnel, pass nitrogen to the four-necked flask to drive away the air, heat up to 160°C, start the agitator, stir at a speed of 550r / min, and wait for the rosin to After all melted, add 40g of rosin, add 35mL of maleic anhydride dropwise to the four-neck flask with a dropping funnel at a dropping rate of 4mL / min while stirring. Diolefination product: add 45mL glycerin to the above-mentioned diolefination product, heat the above-mentioned four-neck flask to 280°C, keep it warm for 8 hours, cool down to room temperature naturally, and discharge the material to obtain the esterification product, and vacuumize the esterification product , control the vacuum degree to be 0.04MPa, take out the small molecule product, obtain the esterified product of purification, namely modified rosin; Alcohol, 12 parts of stannous octoate, and 22 parts of modified rosin are placed in a three-necked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com