a kind of eu 3+ Doped tellurite high-density scintillation glass and preparation method thereof

A scintillation glass, high-density technology, applied in the field of rare earth luminescent materials, can solve the problems of weak luminescence of rare earth ions, high phonon energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] According to the composition: 55TeO 2 -30ZnO-10Lu 2 o 3 -5Eu 2 o 3 (mol%) Weigh the TeO required for a total mass of 20 grams 2 , ZnO, Lu 2 o 3 、Eu 2 o 3 Put the powder raw materials into a mortar, mix well and grind evenly. Pour the uniformly mixed glass raw materials into a crucible, place it in an electric furnace at 900°C for 45 minutes, and then quickly pour the molten glass into a cast iron mold preheated at 350°C. After the glass is formed, transfer it to a 370°C horse Anneal in a furnace for 2 hours, cool down to room temperature naturally, cut, grind and polish the obtained glass to make scintillation glass of 10x10x1.5mm.

Embodiment 2

[0019] According to the composition: 65TeO 2 -25ZnO-8Lu 2 o 3 -2Eu 2 o 3 (mol%) Weigh the TeO required for a total mass of 20 grams 2 , ZnCO 3 、Lu 2 o 3 、Eu 2 o 3 Put the powder raw materials into a mortar, mix well and grind evenly. Pour the uniformly mixed glass raw materials into a crucible, place it in an electric furnace at 1000°C for 50 minutes, and then quickly pour the molten glass into a cast iron mold preheated at 350°C. After the glass is formed, transfer it to a 380°C horse Anneal in a furnace for 2 hours, cool down to room temperature naturally, cut, grind and polish the obtained glass to make scintillation glass of 10x10x1.5mm.

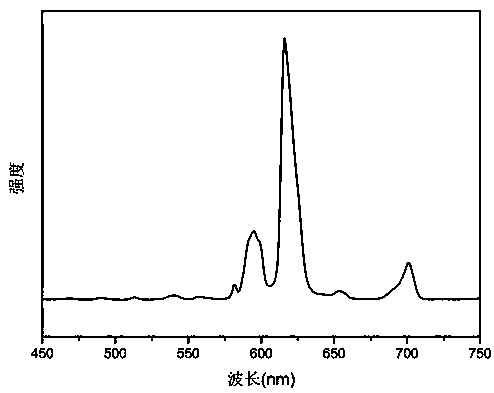

[0020] In this example, a Eu 3+ The emission spectrum of doped tellurate high-density scintillation glass is as follows figure 1 shown.

Embodiment 3

[0022] According to the composition: 70TeO 2 -20ZnO-7Lu 2 o 3 -3Eu 2 o 3 (mol%) Weigh the TeO required for a total mass of 20 grams 2 , ZnO, Lu 2 o 3 、Eu 2 o 3 Put the powder raw materials into a mortar, mix well and grind evenly. Pour the uniformly mixed glass raw materials into a crucible, place it in an electric furnace at 1000°C for 50 minutes, and then quickly pour the molten glass into a cast iron mold preheated at 350°C. After the glass is formed, transfer it to a 490°C horse Anneal in a furnace for 2 hours, cool down to room temperature naturally, cut, grind and polish the obtained glass to make scintillation glass of 10x10x1.5mm.

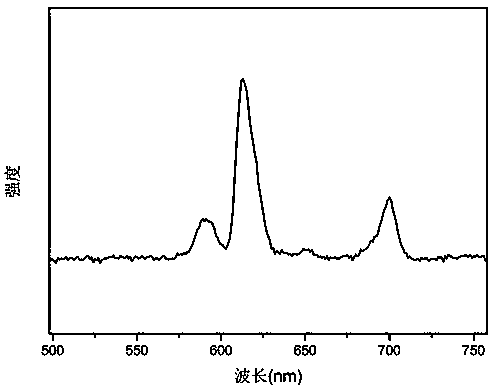

[0023] In this example, a Eu 3+ X-ray excitation spectra of doped tellurate high-density scintillation glass such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com