Control and synthesis method for graphene-like carbon nitride ultrathin nanosheet

A technology of alkene carbonitride and a synthesis method, which is applied in the field of preparation of carbon nitride nanosheets, can solve problems such as difficult reaction control, and achieve the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Weigh 120g of melamine, mix with 1.5g of boric acid, add 100ml of aqueous solution, and heat to 80°C. After the above-mentioned materials are all dissolved in water and appear uniform milky white, they are naturally cooled, and the precipitated composite is mixed with 1 g of carbon fiber uniformly, and then put into a quartz crucible. Place the crucible and the materials in the center of the microwave cavity, evacuate to a pressure of 5kPa in the microwave cavity, set the microwave irradiation power to 6kW, heat it up to 550°C at a rate of 90°C / min and keep it warm for 15 minutes. Natural cooling to obtain the product.

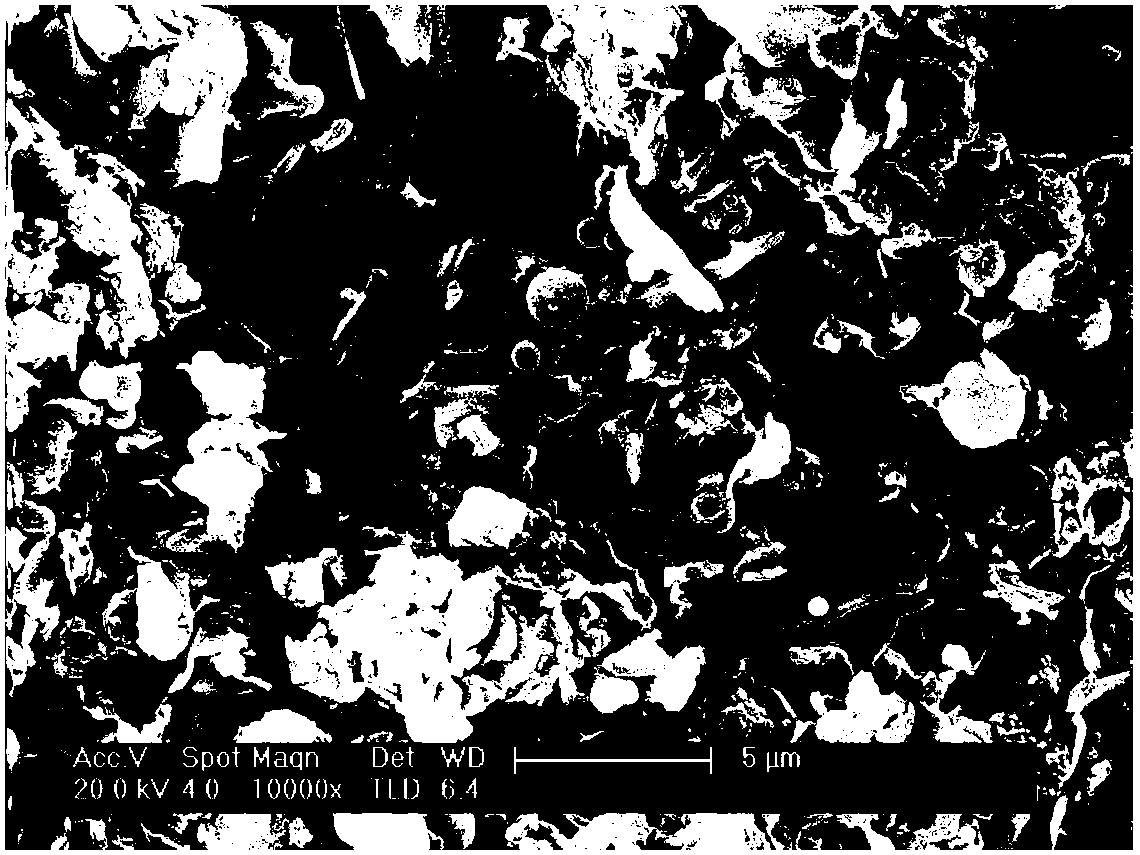

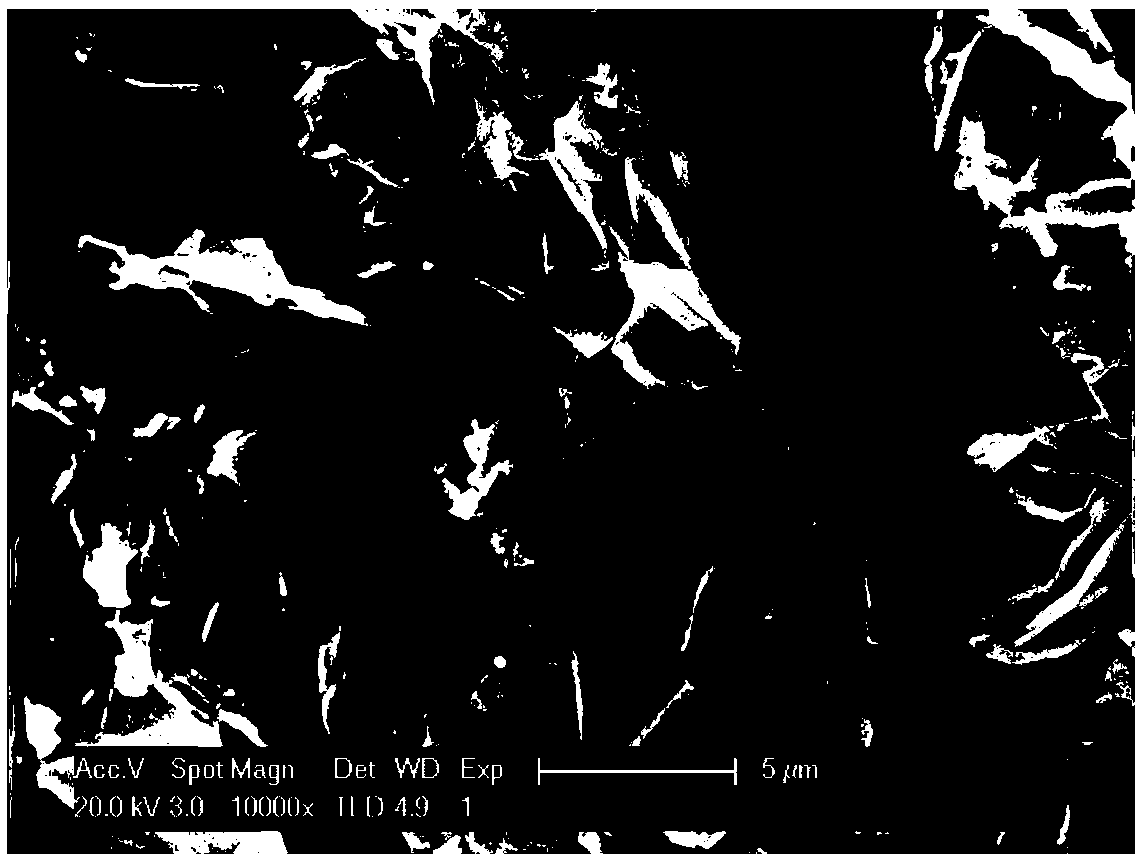

[0044] Using scanning electron microscope (SEM) to observe the product to confirm ( figure 2 ), the obtained products are basically in the form of nanosheets with two-dimensional structure, and the morphology photos of the product of Comparative Example 5 without the addition of morphology control agent ( figure 1 )compared to, figure 2 No obvious powder...

Embodiment 2

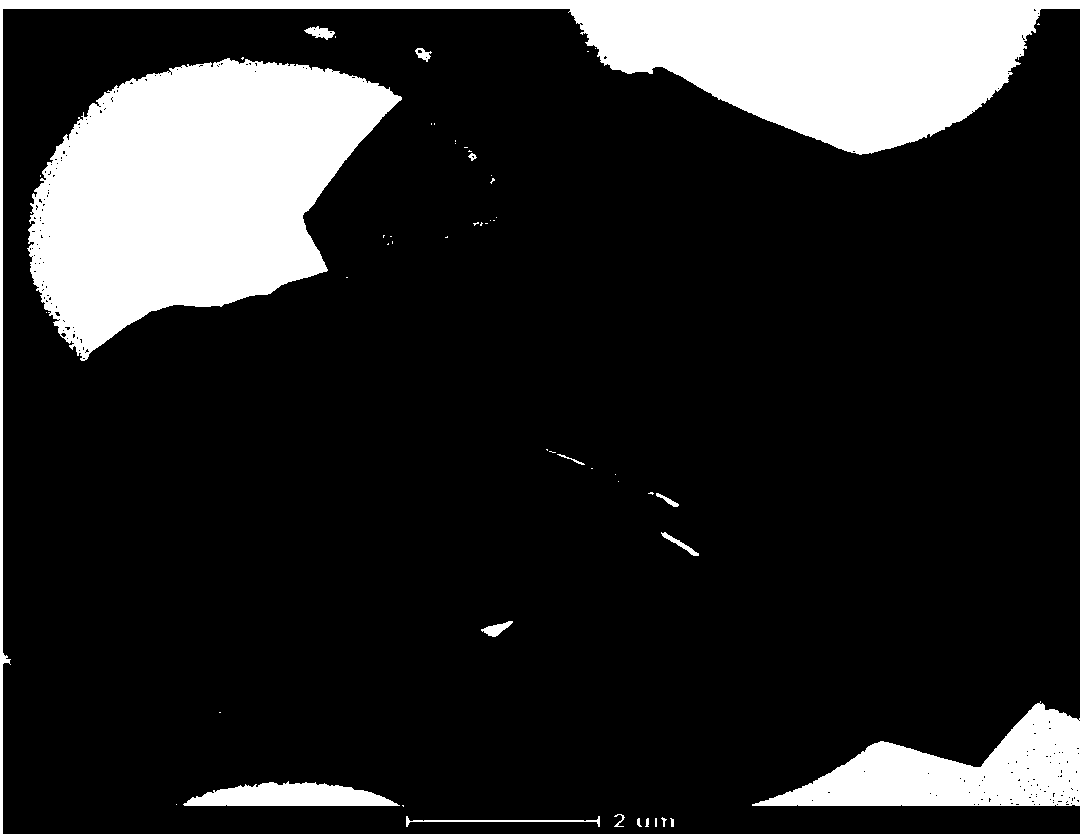

[0046] Weigh 80 g of dicyandiamide, mix with 0.5 g of boron oxide, add 100 ml of aqueous solution, and heat to 70°C. After the above-mentioned materials are all dissolved in water and appear uniform milky white, they are naturally cooled, and the precipitated composite is mixed with 1 g of carbon fiber uniformly, and then put into a quartz crucible. Place the crucible and the materials in the center of the microwave resonant cavity, evacuate to a pressure of 25kPa in the microwave resonant cavity, set the microwave irradiation power to 3kW, heat it up to 520°C at a rate of 50°C / min and heat it for 20 minutes, Naturally cooled ultra-thin carbon nitride nanosheets (Graphene-like gC 3 N 4 ), the thickness is about 2 ~ 3nm.

Embodiment 3

[0048] Weigh 100 g of dicyandiamide and 1.0 g of boron oxide, add 100 ml of aqueous solution after mixing, and heat to 70°C. After the above-mentioned materials are all dissolved in water and appear uniform milky white, they are naturally cooled, and the precipitated composite is mixed with 1 g of carbon fiber uniformly, and then put into a quartz crucible. Place the crucible and the materials in the center of the microwave resonant cavity, evacuate to a pressure of 20kPa in the microwave resonant cavity, set the microwave irradiation power to 4kW, heat it up to 550°C at a rate of 50°C / min and keep it warm for 30 minutes. Naturally cooled ultra-thin carbon nitride nanosheets (Graphene-likeg-C 3 N 4 ), the thickness is about 3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com