A kind of water-based adhesive for automobile filter and preparation method thereof

A water-based adhesive and filter technology, applied in the direction of adhesive types, ester copolymer adhesives, polymer adhesive additives, etc., can solve the problems of slow drying speed, poor antifreeze, and low temperature resistance , achieve the effect of fast drying, strong antifreeze and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 Modified polyetheramine fiber preparation

[0034] The preparation raw material of modified polyetheramine fiber comprises the component of following parts by weight:

[0035] 100 parts of polyetheramine D-230, 150 parts of glyceraldehyde, 5 parts of sodium lauryl sulfate, 15 parts of N,N-methylenebisacrylamide, 5 parts of potassium persulfate, and an appropriate amount of glacial acetic acid.

[0036]Preparation:

[0037] Dissolve polyetheramine D-230 in water to make an aqueous solution with a mass concentration of 100g / L, add sodium lauryl sulfate, stir evenly, heat up to 60°C, add glyceraldehyde, and add appropriate amount of glacial acetic acid to make the pH of the system The value is 3, the solution is fully emulsified, after standing for 10 minutes, add the pre-dissolved concentration of 10g / L N, N-methylenebisacrylamide aqueous solution and 5g / L potassium persulfate aqueous solution, and continue the reaction for 2h, and the reaction Liquid cooli...

Embodiment 2

[0038] Embodiment 2 Acrylic acid-butyl acrylate-styrene copolymer emulsion preparation

[0039] (1) Weigh the polymerized monomer acrylic acid, butyl acrylate and styrene respectively after decompression refining, and mix well. The weight ratio of the acrylic acid, butyl acrylate and styrene is 3.2:4.4:0.9, and then add 2wt % initiator azobisisobutyronitrile (AIBN), mix evenly, then add an appropriate amount of n-butanol to prepare a mixed solution with a solid content of more than 60%, for subsequent use;

[0040] (2) Get 50mL n-butanol and place it in the reactor, heat it up to the solvent reflux temperature, slowly add the mixed solution prepared in step (1) dropwise under uniform stirring, the volume ratio of the mixed solution and n-butanol is 2 : 1, the rate of addition is 0.8mL / min, reflux reaction at 100°C for 6h, after the reaction is over, cool down to 60°C, add ammonia water dropwise under stirring, until the pH value of the system reaches 8, dilute with water, and ...

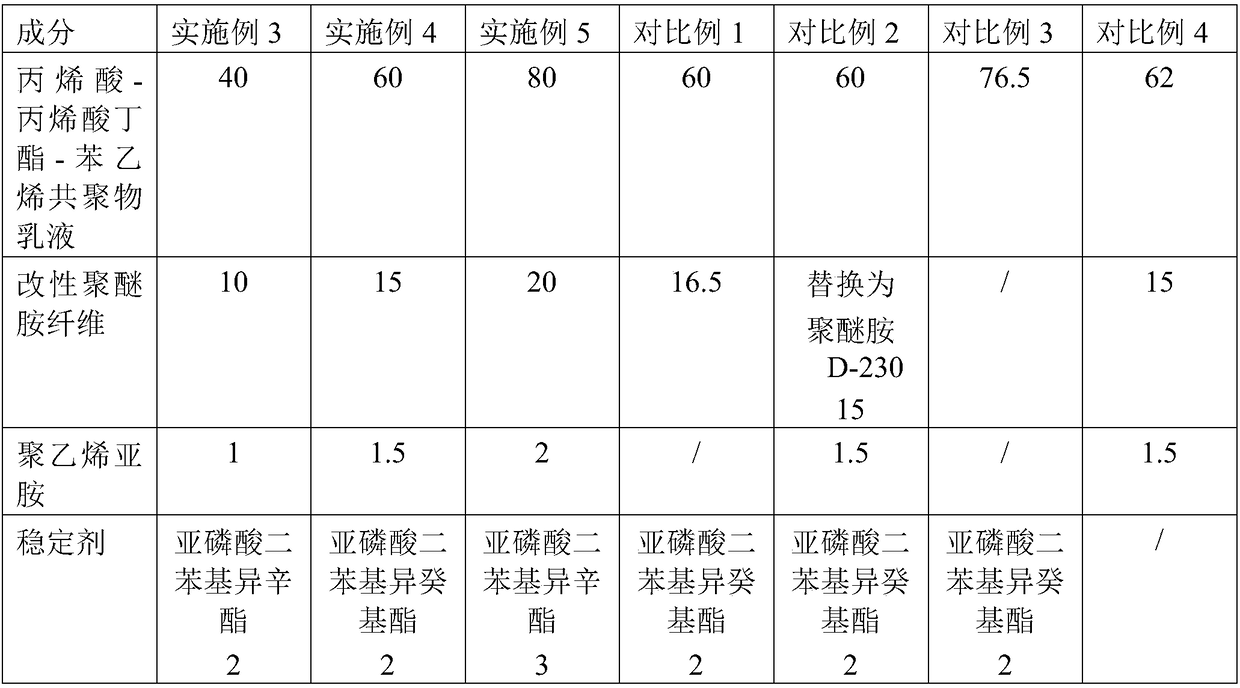

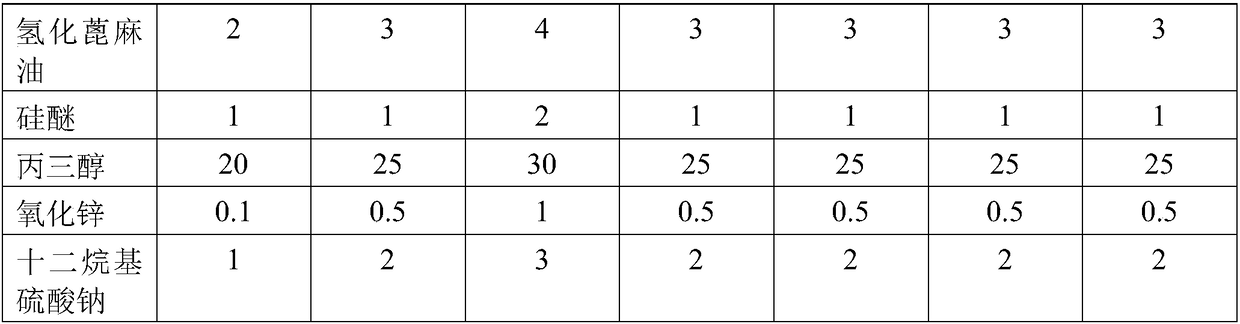

Embodiment 3-5 and comparative example 1-4

[0041] Embodiment 3-5 and comparative example 1-4 water-based adhesive preparation

[0042] Embodiment 3-5 and comparative example 1-4 water-based binder comprise components and parts by weight thereof shown in the table below:

[0043]

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com