Microwave dielectric ceramics and polytetrafluoroethylene-ceramic composite substrate, and preparation methods thereof

A technology of microwave dielectric ceramics and polytetrafluoroethylene, which is applied in the fields of ceramic materials and their preparation, polytetrafluoroethylene-based composite dielectric materials and their substrates, and can solve problems such as difficult industrial production and large temperature coefficient values , achieve low dielectric loss, improve the effect, and simplify the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

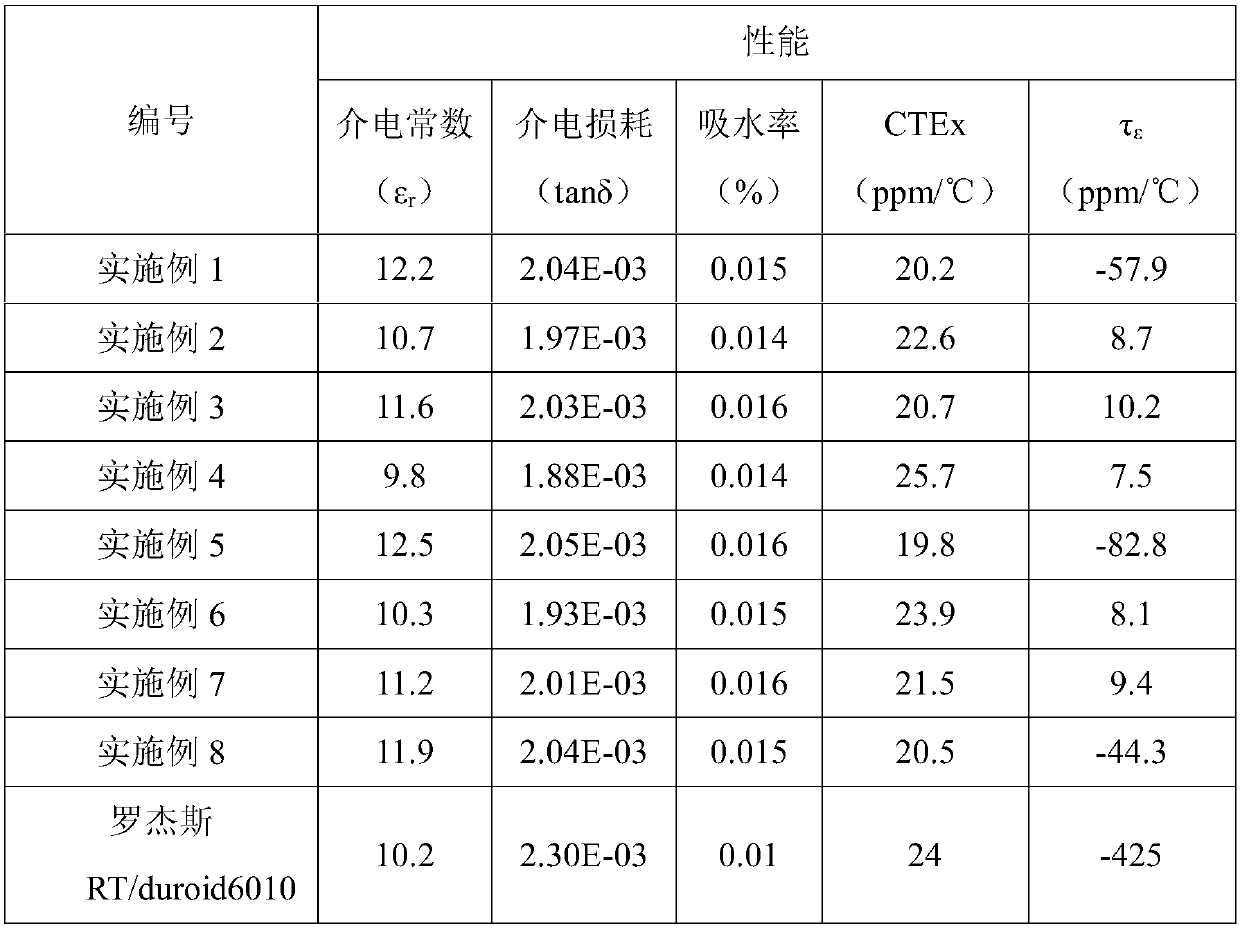

Examples

preparation example Construction

[0037] The preparation method of described ceramic material comprises the following steps:

[0038] (1) Ingredients: According to the general chemical formula Na 0.5-x-y Li x K y SM 0.5-m-n Nd m Bi n TiO 3 , the raw material is selected from Na 2 CO 3 , Li 2 CO 3 、K 2 CO 3 、Sm 2 o 3 、Nd 2 o 3 、 Bi 2 o 3 、TiO 2 , each raw material is determined according to the general chemical formula and the respective mass percentages are accurately weighed;

[0039] (2) Ball milling: the mixture obtained in step (1) is used as the ball milling medium with zirconia balls, and the mass ratio of mixture: balls: absolute ethanol is 1: (3 ~ 5): (1 ~ 2) Ball milling to obtain a uniformly mixed ball mill;

[0040] (3) drying: drying the ball abrasive obtained in step (2) after cleaning to obtain dry ceramics;

[0041] (4) calcining: placing the dried ceramics obtained in step (3) in an alumina crucible to calcinate the ceramic material;

[0042] (5) Ball milling and sieving t...

Embodiment 1

[0067] (1) The sodium carbonate of 15.22g, lithium carbonate of 20.59g, 38.29g samarium trioxide, 93.79g of neodymium trioxide, 15.74g of bismuth trioxide and 134.91g of titanium dioxide are carried out at 25 ℃ for 10 hours Ball milling and mixing to obtain a mixture;

[0068] (2) The obtained mixture was dried at 120°C for 8 hours, and the dried mixture was calcined at 1250°C for 4 hours to obtain the target ceramic;

[0069] (3) the ceramic particles obtained after the ball milling of the gained ceramics at 25° C. for 8 hours were sieved with a standard sampling sieve of 140 objects to obtain ceramic powder;

[0070] (4) Weigh 200g of ceramic powder, dry the ceramic powder in an oven at 120°C for 10h to remove physically adsorbed water, and prepare 150ml of a mixture of hydrogen peroxide and concentrated brine in a three-necked reflux flask (hydrogen peroxide: concentrated brine = 30: 70), and then add the ceramic powder to the mixed solution, boil at 60°C and stir for 1.5h t...

Embodiment 2

[0075] (1) The sodium carbonate of 13.46g, lithium carbonate of 21.90g, 32.48g samarium trioxide, the neodymium trioxide of 99.73g, the bismuth trioxide of 15.78g and the titanium dioxide of 135.25g are carried out at 25 ℃ for 10 hours Ball milling and mixing to obtain a mixture;

[0076] (2) The obtained mixture was dried at 120°C for 8 hours, and the dried mixture was calcined at 1250°C for 4 hours to obtain the target ceramic;

[0077] (3) the ceramic particles obtained after the ball milling of the gained ceramics at 25° C. for 8 hours were sieved with a standard sampling sieve of 140 objects to obtain ceramic powder;

[0078] (4) Weigh 200g of ceramic powder, dry the ceramic powder in an oven at 120°C for 10h to remove physically adsorbed water, and prepare 150ml of a mixture of hydrogen peroxide and concentrated brine in a three-necked reflux flask (hydrogen peroxide: concentrated brine = 30: 70), and then add the ceramic powder to the mixed solution, boil at 60°C and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com