Metal manganese chromium-free passivator and preparation method and application thereof

A chromium-free passivator and metal manganese technology, applied in the field of metallurgy, can solve the problems of reducing the quality of electrolytic metal manganese products, increasing the silicon content, and not having self-healing properties, achieving good biodegradability, slowing down hydrolysis, and good environmental compatibility. capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

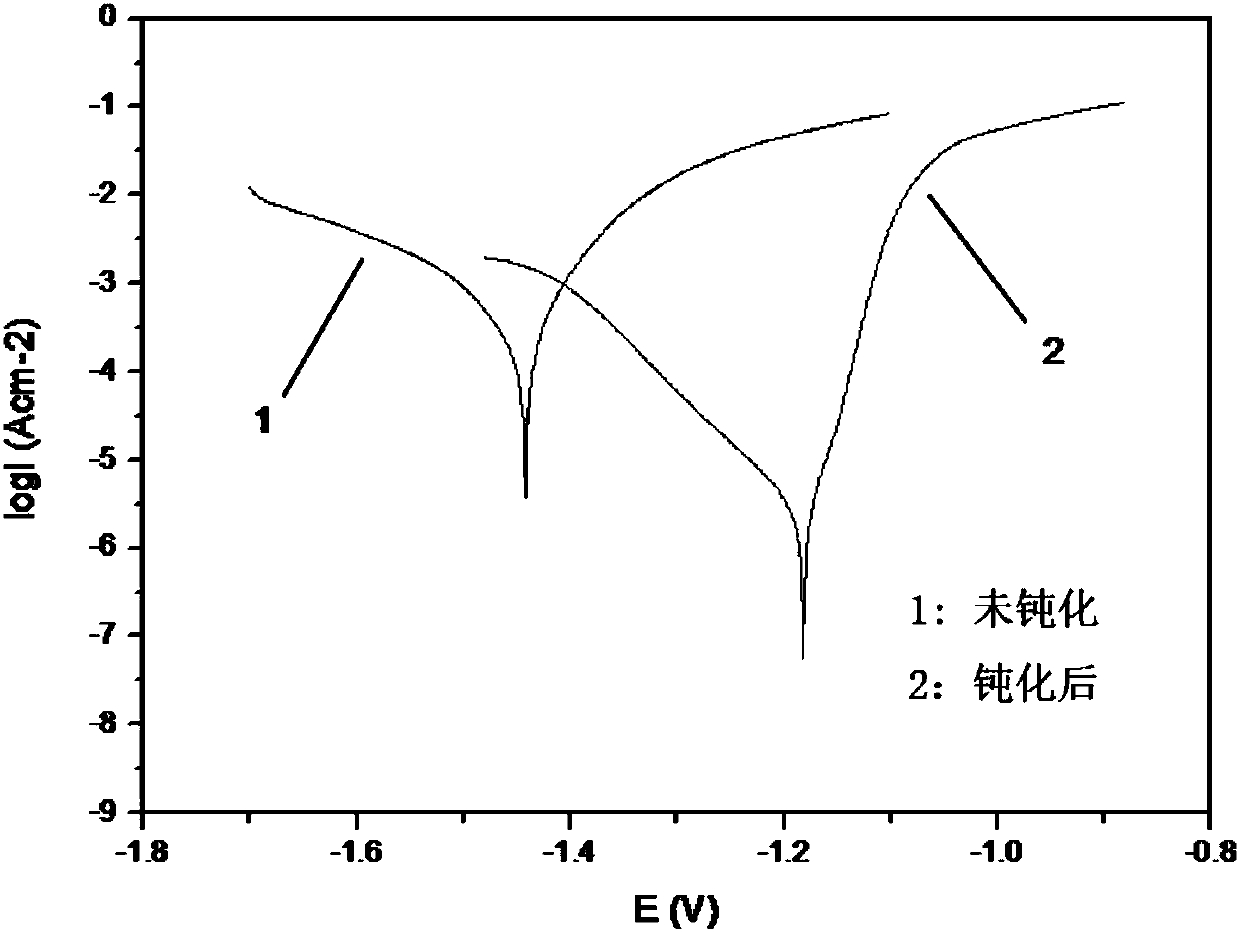

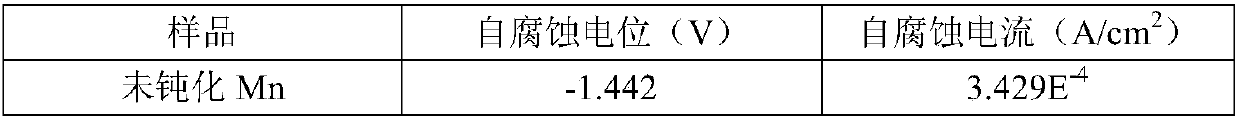

[0042] First, an electrolytic manganese product is prepared in a diaphragm tank by electrolysis: stainless steel is used as a cathode plate, and a lead-silver alloy plate is used as an anode plate. Electrolysis conditions: ammonium sulfate 120g / L, manganese sulfate 35.67g / L, selenium dioxide 0.05g / L catholyte, catholyte pH is about 6.8~7.0, current density is 330A / m 2 , the electrolysis temperature was 38°C, and the electrolysis time was 1.5h. The prepared electrolytic manganese product was used for subsequent passivation experiments and performance evaluation of the passivation layer.

[0043] Preparation of passivation solution: Add 2g of stearic acid, 6g of sodium methyl stearate sulfonate, 2.5g of cerium nitrate and 2.5g of 2-morpholineethanesulfonic acid into 350mL of water, heat and stir at 80°C to dissolve, Then add 7 mL of 30% H 2 o 2 Stir for 1 minute, adjust to pH = 6.0, and prepare a chromium-free passivation solution (mass concentration is about 3%) for electroly...

Embodiment 2

[0061] The preparation of the electrolytic manganese metal product is the same as in Example 1.

[0062] Preparation of passivation solution: 2g of stearic acid, 2g of sodium stearate methyl sulfonate, 4.5g of cerium nitrate and 3.5g of 2-morpholineethanesulfonic acid were added to 350mL of water, followed by 15mL of 30% h 2 o 2 Stir for 1 minute, heat and stir to dissolve at 80° C., adjust to pH=6.0, and prepare a chromium-free passivation solution for electrolytic metal manganese surface treatment. The mass ratio of stearic acid, sodium methyl stearate sulfonate, cerium nitrate and 2-morpholineethanesulfonic acid in the passivator is 1:1:2.25:1.75.

[0063] Passivation and performance testing of electrolytic manganese products: Put the chromium-free passivation solution in the passivation tank, rinse the surface of the cathode plate after electrolysis with clean water, then put the cathode plate into the passivation tank, and immerse the chromium-free passivation solution ...

Embodiment 3

[0066] The preparation of electrolytic manganese metal is the same as in Example 1.

[0067] Preparation of the mixture of stearic acid and sodium stearate methyl sulfonate: Weigh 30g of stearic acid and 20mL of methanol into a 250mL four-neck flask, add 1mL of concentrated sulfuric acid, stir and reflux at 80°C for 20h, stop the reaction , wash the product with hot water at 60°C for 3 times, adjust the pH to 7.5 with sodium hydroxide, and cool to obtain the intermediate esterification product; put the esterification product, 12mL of chloroform and 2g of sodium sulfate in a four-necked flask, and heat to 35-40 ℃, and control the temperature below 50℃, add 7g of chlorosulfonic acid dropwise, then slowly raise the temperature to 70℃, stir for 1h, cool to obtain the sulfonated product; control the temperature at 40~50℃, neutralize the sulfonic acid with 20% NaOH The product was oxidized to control its pH to about 8, and then 20 mL of H was added 2 o 2 (mass fraction is 30%) to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com