Carbon coating treatment method for copper-aluminum-silicon nano alloy material and application of carbon coating treatment method

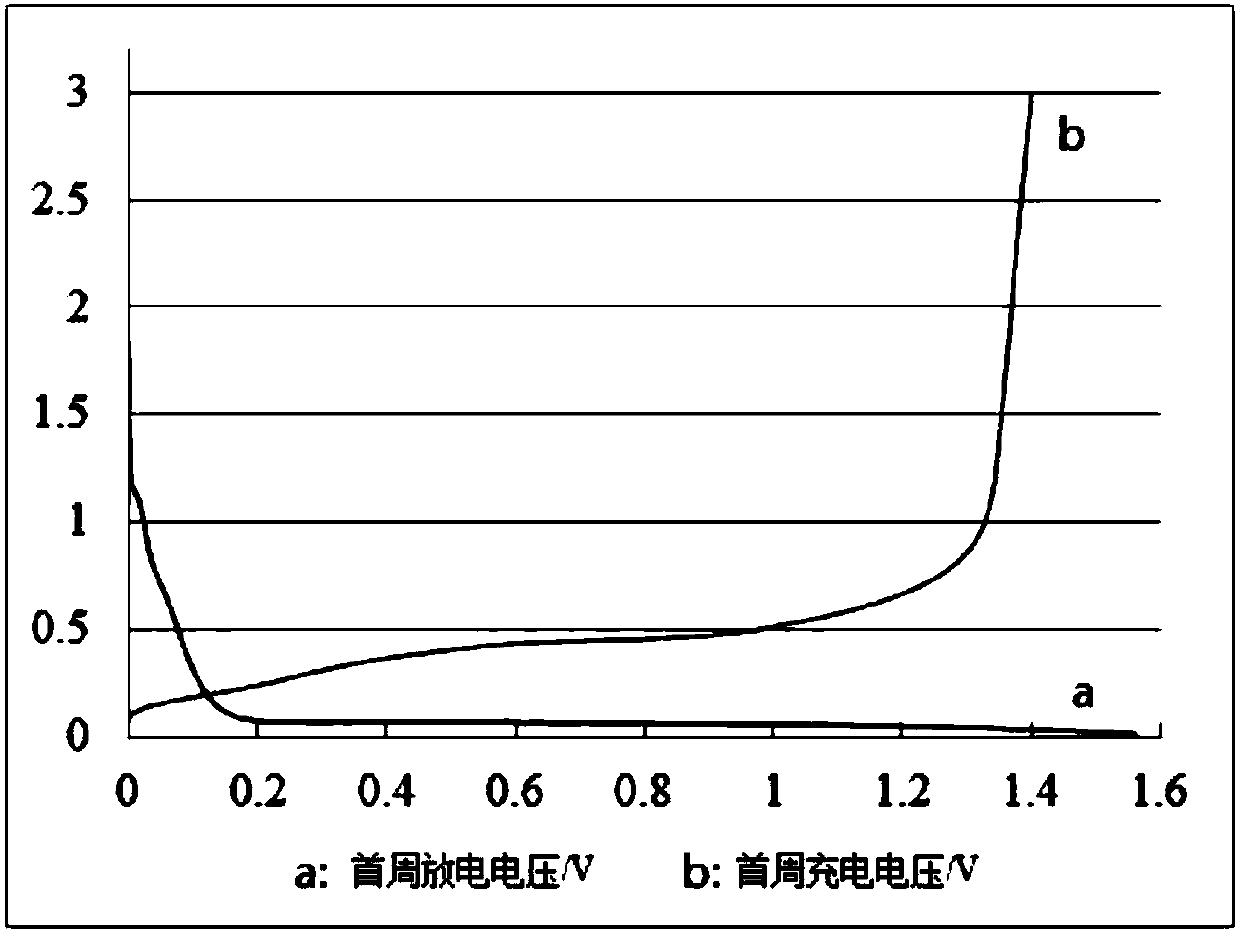

A processing method and alloy material technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of low first-week efficiency, short cycle life, long charge and discharge time, etc., to meet coating requirements, reasonable particle size distribution, The unique effect of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

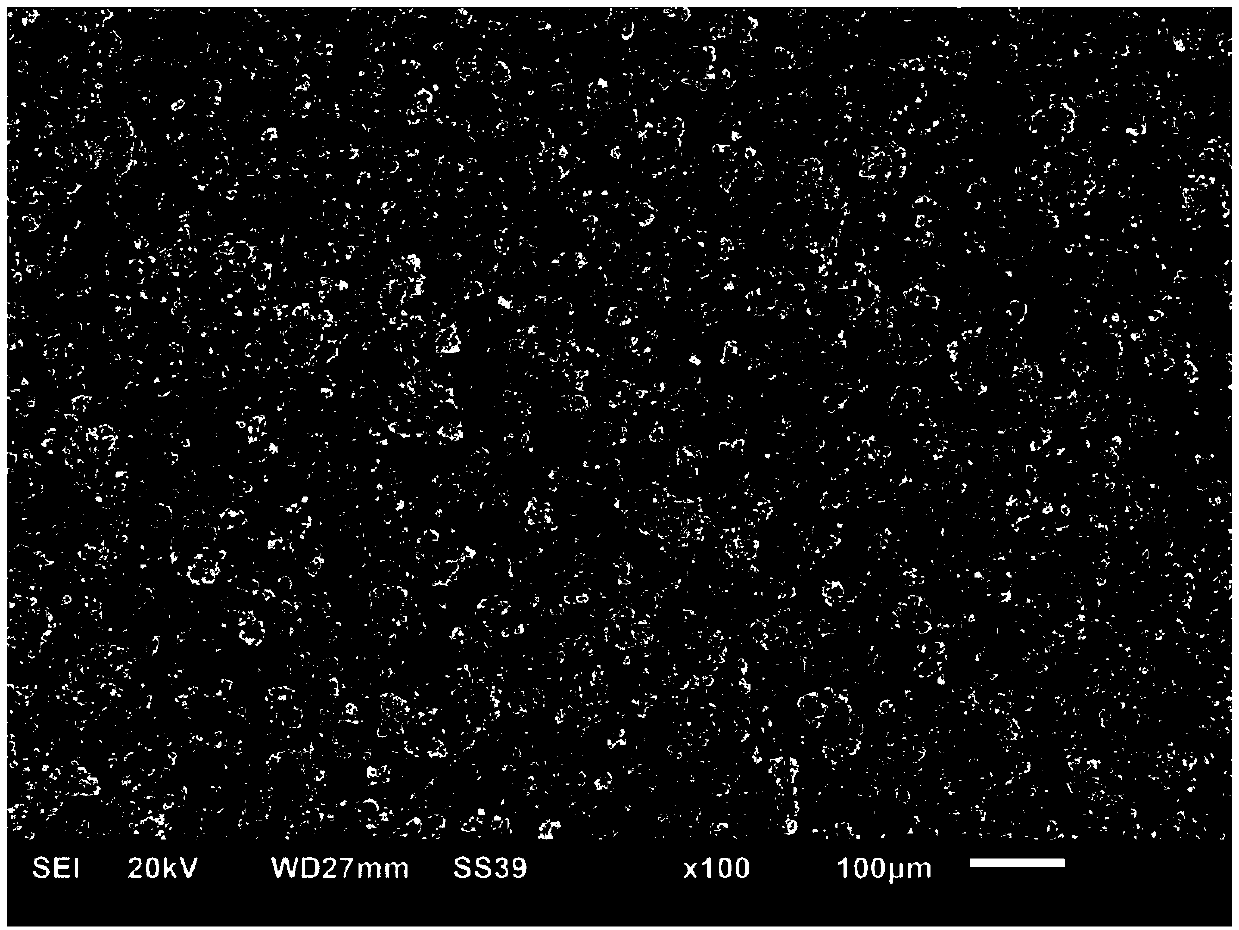

Embodiment 1

[0062] (1) Ingredients of Cu-Al-Si alloy,

[0063] Cut pure copper into φ50mm×100mm rods, pre-treat with pickling and vacuum drying before use, and control the drying temperature at 110±5°C; cut pure aluminum into 50mm×50mm×30mm small aluminum plates, and use acid before use Washing plus vacuum drying pretreatment, the drying temperature is controlled at 200±5°C; the block size of metal silicon is controlled at 5-30mm, pickling before use to remove surface impurities, and then vacuum drying, the drying temperature is controlled at 180± 5°C. The total weight of ingredients is 20Kg, of which by weight: 22-27.5 parts of silicon, 60-70 parts of copper, 0.5-10 parts of aluminum, 0-5 parts of impurities, impurities include: titanium, cobalt, nickel, manganese, iron, boron , phosphorus, carbon, etc., first add part of the silicon, then add copper and aluminum, then add the remaining silicon, and start heating.

[0064] (2) Smelting of Cu-Al-Si alloy:

[0065] Select the technical ...

Embodiment 2

[0087] Example 2, the composition of the copper-aluminum-silicon alloy is in parts by weight: 27.5-32 parts of silicon, 58-63 parts of copper, 1-11 parts of aluminum, 0-5 parts of impurities, molten copper- The furnace temperature of aluminum-silicon alloy is 1550 ± 50 ℃, other steps and methods are basically similar to embodiment 1, Figure 6-10 Shown, the performance of the final product of this embodiment and embodiment 1 is basically the same.

Embodiment 3

[0088] Example 3, the composition of the copper-aluminum-silicon alloy is by weight: 32-39 parts of silicon, 54-59 parts of copper, 1-8 parts of aluminum, 0-5 parts of impurities, molten copper- The outgoing temperature of aluminum-silicon alloy is 1650 ± 50 ℃, other steps and methods are basically similar to embodiment 1, Figure 11-20 Shown, the performance of the final product of this embodiment and embodiment 1 is basically the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com