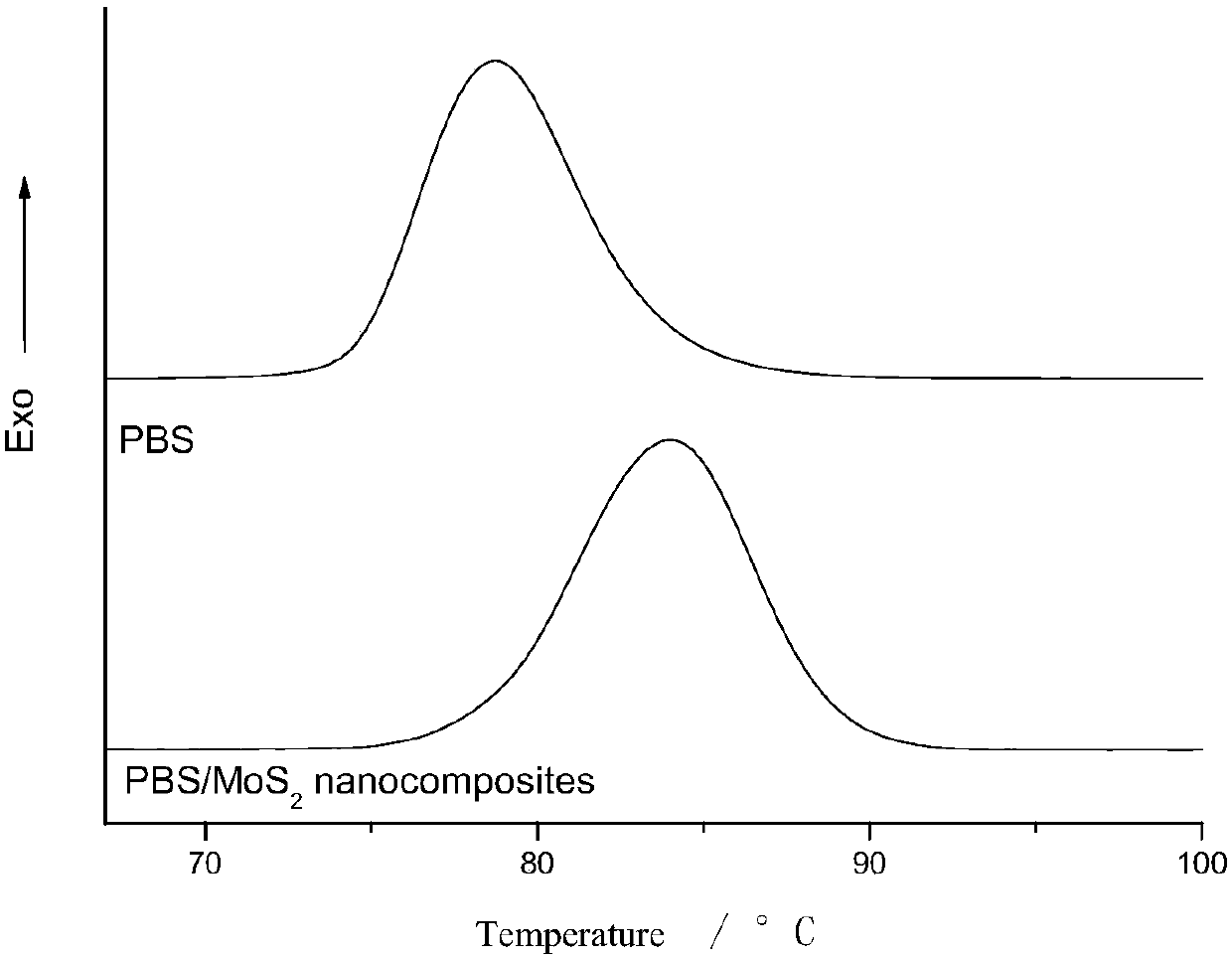

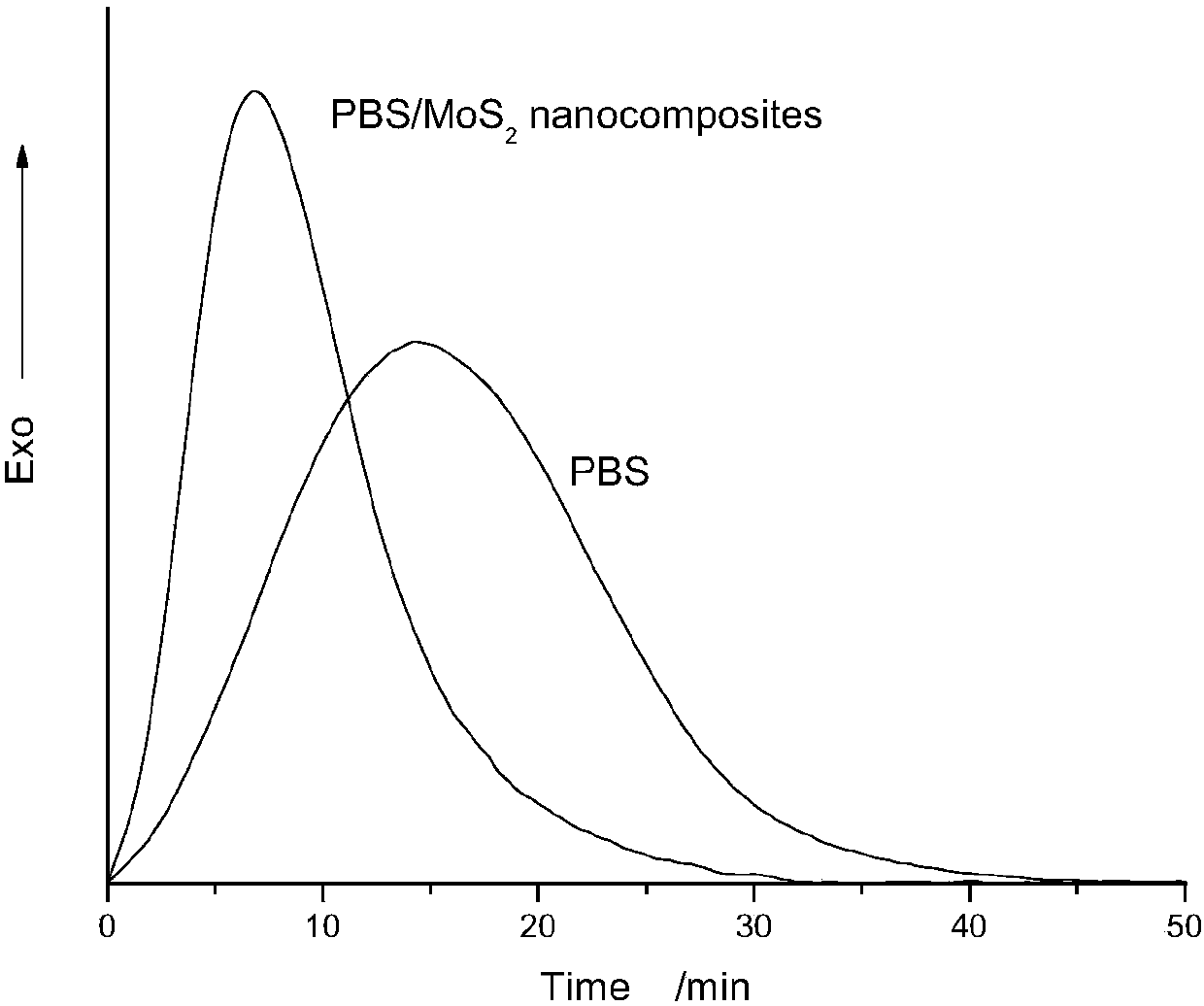

Preparation method for polybutylene succinate/graphene-molybdenum-disulfide-like nanocomposite material

A technology of polybutylene succinate and nano-composite materials, applied in the field of biodegradable materials, can solve the problems of poor gas-liquid barrier property, poor melt strength, slow crystallization rate, etc. the effect of reducing the nucleation energy barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Mix deionized water and butanediol at a molar ratio of 1:0.8 to obtain a butanediol / water mixture; add molybdenum disulfide powder to the above-mentioned butanediol / water mixture at a ratio of 2 mg / mL, and seal Under the power of 300W, liquid phase ultrasonication at room temperature for 40h, and then centrifuged at 10000rpm for 30min, the upper layer of dark green liquid was retained, and a stable graphene-like molybdenum disulfide dispersion was obtained.

[0027] Add 11.81g of succinic acid to 12.40g of the above-mentioned graphene-like molybdenum disulfide dispersion, raise the temperature to 170-210°C under the protection of nitrogen, and vigorously stir mechanically until no water is formed in the water separator to obtain graphene-like molybdenum disulfide Molybdenum hydroxyl-terminated prepolymer.

[0028] Quickly add 0.11g catalyst n-butyl titanate to the above-mentioned hydroxyl-terminated prepolymer containing graphene-like molybdenum disulfide under stirring...

Embodiment 2

[0030] Mix deionized water and butanediol at a molar ratio of 1:1 to obtain a butanediol / water mixture; add molybdenum disulfide powder to the above-mentioned butanediol / water mixture at a ratio of 2 mg / mL, and seal the Liquid phase ultrasonication at room temperature for 16 hours at 600W power, and then centrifuged at 10,000rpm for 30 minutes to retain the dark green liquid in the upper layer to obtain a stable graphene-like molybdenum disulfide dispersion.

[0031] Add 11.81g of succinic acid to 12.98g of the above-mentioned graphene-like molybdenum disulfide dispersion, raise the temperature to 180-225°C under the protection of nitrogen, and vigorously stir mechanically until no water is generated in the water separator to obtain graphene-like molybdenum disulfide Molybdenum hydroxyl-terminated prepolymer.

[0032] Quickly add 0.22g of catalyst germanium dioxide to the above-mentioned hydroxyl-terminated prepolymer containing graphene-like molybdenum disulfide under stirrin...

Embodiment 3

[0034] Mix deionized water and butanediol at a molar ratio of 1:1.5 to obtain a butanediol / water mixture; add molybdenum disulfide powder to the above-mentioned butanediol / water mixture according to the ratio of 2 mg / mL, and seal the Under the power of 540W, liquid phase ultrasonication at room temperature was carried out for 24 hours, and then centrifuged at a speed of 10,000 rpm for 30 minutes, and the upper layer of dark green liquid was retained to obtain a stable graphene-like molybdenum disulfide dispersion.

[0035] Add 11.81g of succinic acid to 10.73g of the above-mentioned graphene-like molybdenum disulfide dispersion, raise the temperature to 160-200°C under the protection of nitrogen, and vigorously stir mechanically until no water is formed in the water separator to obtain graphene-like molybdenum disulfide Molybdenum hydroxyl-terminated prepolymer.

[0036] Quickly add 0.11g catalyst n-butyl titanate to the above-mentioned hydroxyl-terminated prepolymer containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com