Anti-scratching highlight RC printing paper and preparation method thereof

An anti-scratch, photographic paper technology, applied in reproduction/marking methods, coating, printing, etc., can solve the problems of complex process, high price, low yield, etc., and achieve the effect of low cost, good hue and good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

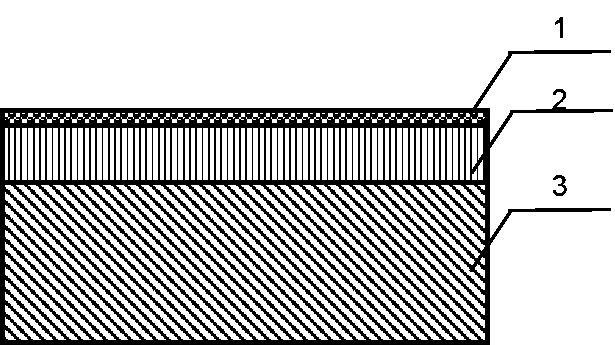

Image

Examples

preparation example Construction

[0024] The preparation method of anti-scratch high-gloss RC photographic paper of the present invention specifically comprises the following steps:

[0025] (1) Provide the original high-gloss RC paper, the paper base is made of whole wood pulp or mixed wood pulp, and then coated with polyethylene film on both sides. The glossiness of high-gloss RC paper is higher than 65% (60°, GB / T 8941-2007).

[0026] (2) Preparation of ink absorbing layer coating

[0027] Preparation of the dispersion: under stirring, slowly add 100 parts of nano-alumina, 0.5-1.0 parts of pH regulator and 0.5-1.0 parts of silane coupling agent into deionized water, then slowly increase the stirring speed to above 2000r / min, Disperse at high speed for 30 minutes to make a dispersion with a solid content of 20% to 30%.

[0028] Aging of the dispersion: place the above-prepared dispersion in a water bath at 60±5°C for more than 8 hours to ensure sufficient hydrolysis of the silane coupling agent.

[0029] ...

Embodiment 1

[0045] High-gloss RC paper adopts all-wood pulp short-fiber RC paper coated with polyethylene film on both sides, and the basis weight of the paper is 165g / m 2 , gloss 68% (60°, GB / T 8941-2007).

[0046] Ink absorbing layer coating: 100 parts of nano-alumina, 10 parts of adhesive, 0.5 part of pH regulator, 0.5 part of silane coupling agent, 20 parts of defoaming agent, 0.2 part of leveling agent, and 0.2 part of crosslinking agent. The binder is polyvinyl alcohol, the pH regulator is 10% nitric acid aqueous solution, the defoamer is isopropanol, and the leveling agent is a fluorine-modified acrylic acid copolymer. The cross-linking agent described is boric acid.

[0047] Use a screw gap type scraper to coat the ink-absorbing layer paint on the surface of RC paper, heat and dry to form an ink-absorbing layer, and the coating amount is 25g / m 2 .

[0048] Anti-scratch gloss coating: 40 parts of fine transparent powder, 60 parts of nano-alumina, 10 parts of adhesive, 1.0 part o...

Embodiment 2

[0051] High-gloss RC paper adopts all-wood pulp short-fiber RC paper coated with polyethylene film on both sides, and the basis weight of the paper is 190g / m 2 , glossiness 67% (60°, GB / T 8941-2007).

[0052] Ink absorbing layer coating: 100 parts of nano-alumina, 15 parts of adhesive, 0.5 part of pH regulator, 0.5 part of silane coupling agent, 20 parts of defoaming agent, 0.2 part of leveling agent, and 0.2 part of crosslinking agent. Described binding agent is that polyvinyl alcohol and styrene-butadiene latex are mixed in the ratio of 5:1, and described pH adjusting agent is 10% nitric acid aqueous solution, and described antifoaming agent is isopropanol, and described leveling agent It is a fluorine-modified acrylic copolymer, and the cross-linking agent is boric acid.

[0053] Use a screw gap type spatula to coat the ink-absorbing layer paint on the surface of RC paper, heat and dry to form an ink-absorbing layer, and the coating amount is 26g / m 2 .

[0054] Anti-scra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com