Negative plate of secondary nickel-iron battery, preparation method of negative plate and secondary nickel-iron battery of using negative plate

A secondary battery and negative plate technology, which is applied to battery electrodes, nickel storage batteries, alkaline storage batteries, etc., can solve the problems that it is difficult to make up the gap between energy density and power density, and achieve improved hydrogen evolution overpotential, long cycle life, and reduced The effect of the hydrogen evolution reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

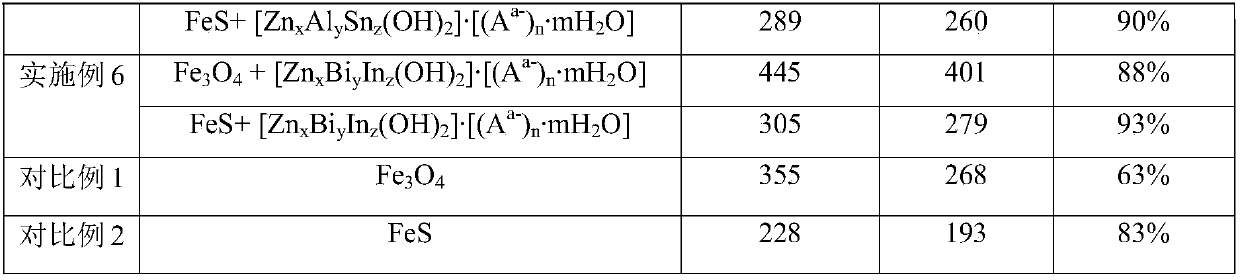

Examples

Embodiment 1

[0024] [Zn x Ti y (OH) 2 ]·[(A a- ) n ·mH 2 O](Zn / Ti=4 / 1,A=S 2- ) preparation of additives

[0025]In a fume hood, dissolve the titanium tetrachloride solution in a certain amount of deionized water, add zinc chloride, control the molar ratio of titanium tetrachloride to zinc salt to be Zn / Ti=4 / 1, and then add a certain amount of The amount of urea was mixed into a zinc-titanium composite salt solution with a molar concentration of 2 mol / L after stirring; the zinc-titanium composite salt solution was moved into a hydrothermal reactor and hydrothermally treated at 180 ° C for 25 hours, and then filtered to obtain an intermediate product white powder ; Transfer the white powder to a sodium sulfide solution with a molar concentration of 1 mol / L, treat it at 80°C for 5 hours under inert gas nitrogen, and then filter, wash and dry to obtain the target product.

[0026] Application of additives: (1) 75g of triiron tetroxide, synthesized [Zn x Ti y (OH) 2 ]·[(A a- ) n ·mH...

Embodiment 2

[0029] [Zn x Bi y (OH) 2 ]·[(A a- ) n ·mH 2 O](Zn / Bi=3 / 1,A=CO 3 2- ) preparation of additives

[0030] The bismuth sulfate is dissolved in the nitric acid solution, and zinc sulfate is added, wherein the molar ratio of bismuth sulfate and zinc sulfate is controlled as (Zn / Bi=3 / 1), and then the deionized water is added and the molar concentration is 2mol / L of zinc. Bismuth complex salt solution; dissolving sodium hydroxide in deionized water to prepare a sodium hydroxide solution with a molar concentration of 2 mol / L; adding the sodium hydroxide solution dropwise to the zinc-bismuth complex salt solution under the reaction conditions of 30 °C, Stir continuously until the pH of the mixed solution is 8 after the reaction is completed; transfer the mixed solution into a hydrothermal reaction kettle for hydrothermal treatment at 130 ° C for 15 h, cool to room temperature, filter, wash and dry to obtain a white powder; the obtained white powder Transfer to the prepared sodiu...

Embodiment 3

[0034] [Zn x Ti y Cu z (OH) 2 ]·[(A a- ) n ·mH 2 O](Zn / Ti / Cu=4 / 1 / 1, A=WO 4 2- , OH - ) preparation of additives

[0035] In a fume hood, dissolve the titanium tetrachloride solution in a certain amount of deionized water, add zinc chloride and copper chloride, control the molar ratio of Zn / Ti / Cu to 4 / 1 / 1, and then add a certain amount of Amount of urea was mixed into a compound salt solution with a molar concentration of 3 mol / L after stirring; the compound salt solution was moved into a hydrothermal reactor and hydrothermally treated at 170 ° C for 25 hours, and then filtered to obtain an intermediate product white powder; the white powder was It was transferred to an alkaline solution of sodium tungstate with a molar concentration of 2 mol / L with a pH value of 14, treated at 100 °C for 10 h under inert gas nitrogen, and then filtered, washed and dried to obtain the target product.

[0036] Application of additives: (1) 65g of triiron tetroxide, synthesized Zn x Ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com