A kind of halogen-free flame-retardant high-gloss mineral fiber reinforced PC/ABS composite material and its preparation method

A composite material and mineral fiber technology, applied in the field of polymer material modification, can solve the problems of long processing cycle, low production efficiency and high manufacturing cost, and achieve the effect of increasing compatibility and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the halogen-free flame-retardant high-gloss mineral fiber reinforced PC / ABS material described in this embodiment includes the following steps:

[0029] 1) Drying the mineral fiber material, spraying a silane coupling agent solution on the surface to mix, drying and cooling to obtain a surface-treated mineral fiber material;

[0030] 2) Add the PC, ABS, silsesquisilicone flame retardant, stabilizer, toughening agent, anti-dripping agent, compatibilizer, coupling agent and anti-floating fiber leakage agent into the high-speed mixing In the machine, mix at high speed for 2-10 minutes to obtain the main feed mixture;

[0031]3) Put the above-mentioned main feed mixture into an intermeshing co-rotating twin-screw extruder to melt and extrude, and add the organophosphorus flame retardant and surface-treated mineral fiber materials through side feeding according to the ratio, and melt the reaction , extrusion, cooling, pelletizing, and drying to obt...

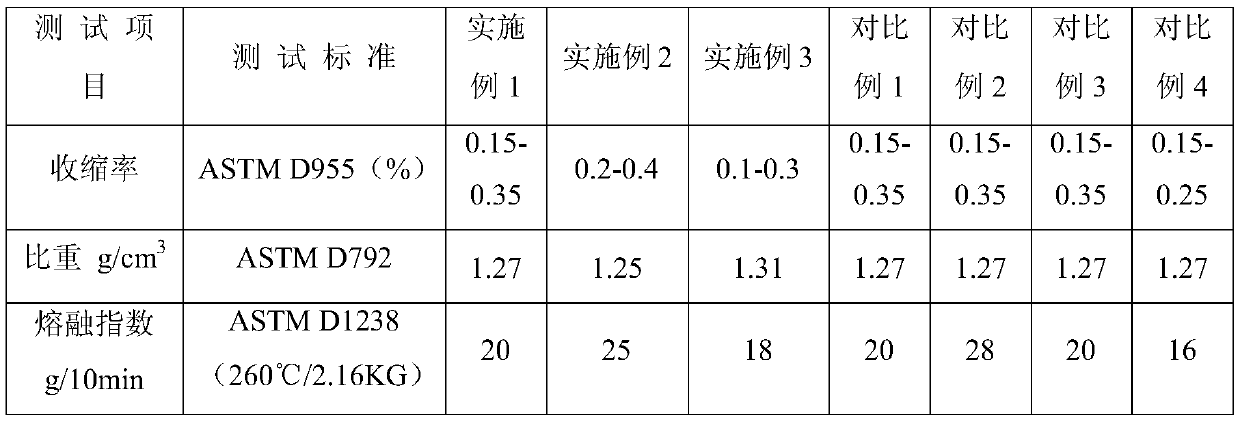

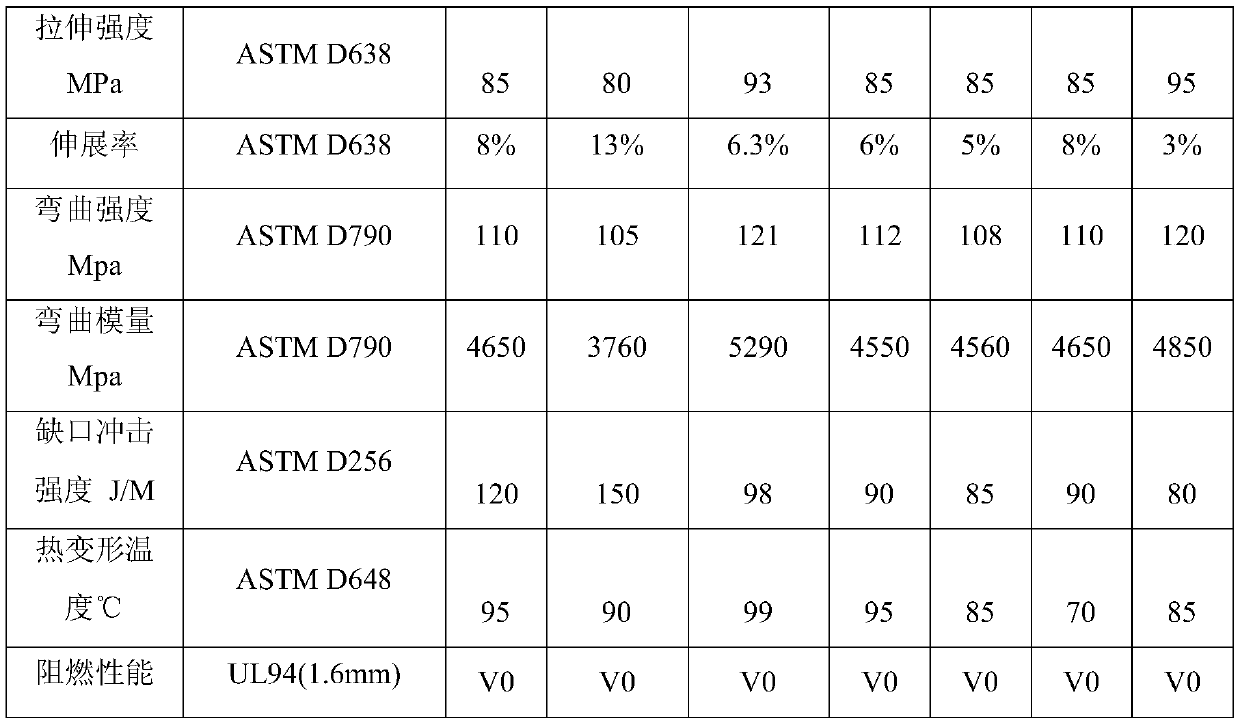

Embodiment 1

[0037] The mass to weight ratio of PC 59.8%, ABS 10%, POSS 0.2%, anti-dripping agent DB105 0.3%, compatibilizer SMA700 2.0%, compound toughening agent 4.0% (is high rubber powder, MBS, acid polyethylene Wax mixture, the mass ratio is 1:2:1), 0.1% stabilizer, 0.3% coupling agent KH550, 0.3% anti-glass fiber leakage agent, stirred in a mixing bucket for 5 minutes, BDP8.0%, talcum powder 15% is added through the side feeding of the weighing scale, and is melt-extruded and granulated by a twin-screw extruder. The processing technology is as follows: twin-screw extruder 1 zone 180°C, zone 2 250°C, zone 3 250°C, zone 4 250°C, zone 5 230°C, zone 6 210°C, zone 7 210°C, zone 8 210°C, The eighth zone is 260°C; the screw speed is 300-450 rpm.

Embodiment 2

[0039] The mass ratio of PC 64.8%, ABS 10%, POSS 0.2%, anti-dripping agent 0.3%, compatibilizer SMA700 2.0%, compound toughening agent 4.0% (which is the product of high rubber powder, MBS, acid polyethylene wax Mixture, the mass ratio is 1:2:1), stabilizer 0.1%, coupling agent KH550 0.3%, glass fiber leakage prevention agent 0.3%, stirred in a mixing bucket for 5 minutes, BDP 8.0%, talcum powder 10% through The side feeding of the weighing scale is added, and the pellets are melted and extruded by a twin-screw extruder. The processing technology is as follows: twin-screw extruder 1 zone 180°C, zone 2 250°C, zone 3 250°C, zone 4 250°C, zone 5 230°C, zone 6 210°C, zone 7 210°C, zone 8 210°C, The eighth zone is 260°C; the screw speed is 300-450 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com