Catalyst for preparing n-Butyl butyrate by n-butanal and preparation method thereof

A technology of n-butyl n-butyrate and n-butyraldehyde is applied in catalyst activation/preparation, aldehyde redox preparation, chemical instruments and methods, etc. Highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

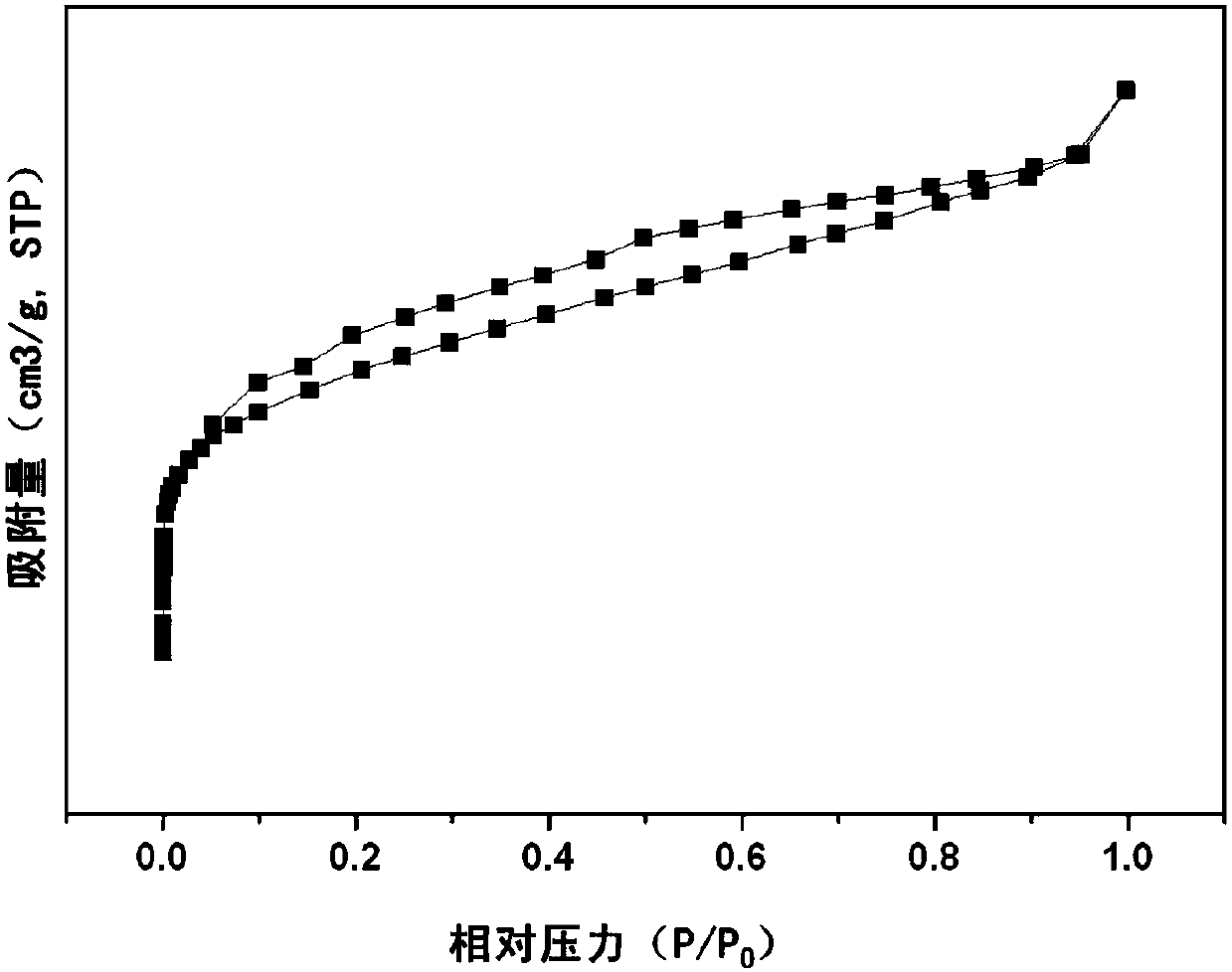

Embodiment 1

[0032] Add 50g of 1,2-dichloroethane into the flask as a solvent, add 2g of phenol, 5g of dimethoxymethane, add 2g of ferric chloride under vigorous stirring, heat to 80°C, phenol and dimethyl Oxymethane is homogeneously polymerized under the action of ferric chloride, and the polymerization time is 12h. Soxhlet extraction was performed on the obtained solid with ethanol as a solvent for 18 hours to obtain a hydroxyl-rich porous organic polymer material POP. The obtained porous organic polymer material was dispersed in toluene, 3.6 g of tert-butyllithium was added, and stirred at room temperature for 4 h. The polymer POP-Li was obtained by suction filtration. The obtained POP-Li was redispersed in toluene, 5g of ruthenium trichloride was added, heated to 80°C, stirred for 4 hours, and the polymer POP-Ru was obtained by suction filtration.

Embodiment 2

[0034] Add 25g of 1,2-dichloroethane into the flask as a solvent, add 2g of phenol and 5g of dimethoxymethane, add 1g of ferric chloride under vigorous stirring, and heat to 85°C to make phenol and dimethoxymethane Methoxymethane is homogeneously polymerized under the action of ferric chloride, and the polymerization time is 20h. The obtained solid was subjected to Soxhlet extraction with ethanol as a solvent for 12 hours. A hydroxyl-rich porous organic polymer material POP was obtained. The obtained porous organic polymer material was dispersed in toluene, 3.6 g of n-butyllithium was added, and stirred at room temperature for 5 h. The polymer POP-Li was obtained by suction filtration. The obtained POP-Li was redispersed in cyclohexane, 5 g of ruthenium acetylacetonate was added, heated to 60° C., stirred for 7 h, and the polymer POP-Ru was obtained by suction filtration.

Embodiment 3

[0036] Add 50g of 1,2-dichloroethane into the flask as a solvent, add 2g of phenol and 6g of dimethoxymethane, add 0.5g of ferric chloride under vigorous stirring, heat to 90°C, phenol and dimethoxymethane Methoxymethane is homogeneously polymerized under the action of ferric chloride, and the polymerization time is 24h. The obtained solid was subjected to Soxhlet extraction with ethanol as a solvent for 24 hours. A hydroxyl-rich porous organic polymer material POP was obtained. The obtained porous organic polymer material was dispersed in toluene, 4.2 g of tert-butyllithium was added, and stirred at room temperature for 6 h. The polymer POP-Li was obtained by suction filtration. The obtained POP-Li was redispersed in toluene, 6g of ruthenium nitrate was added, heated to 100°C, stirred for 6h, and the polymer POP-Ru was obtained by suction filtration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com