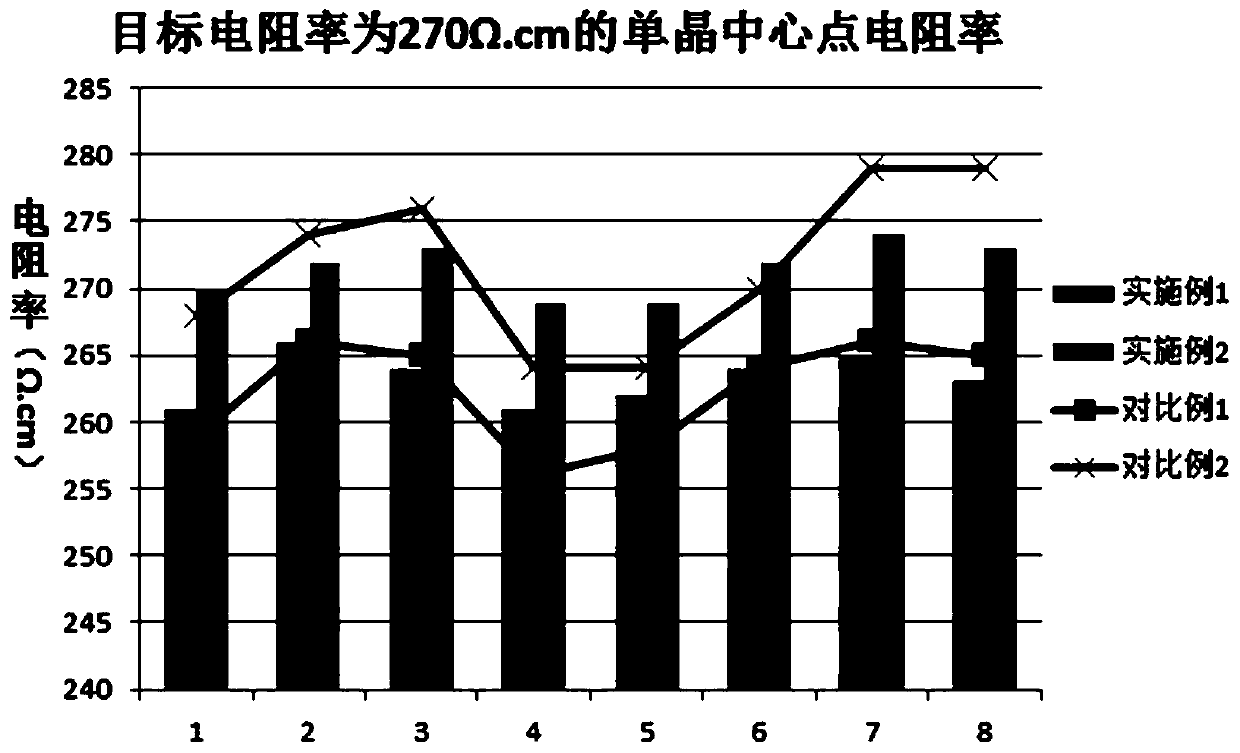

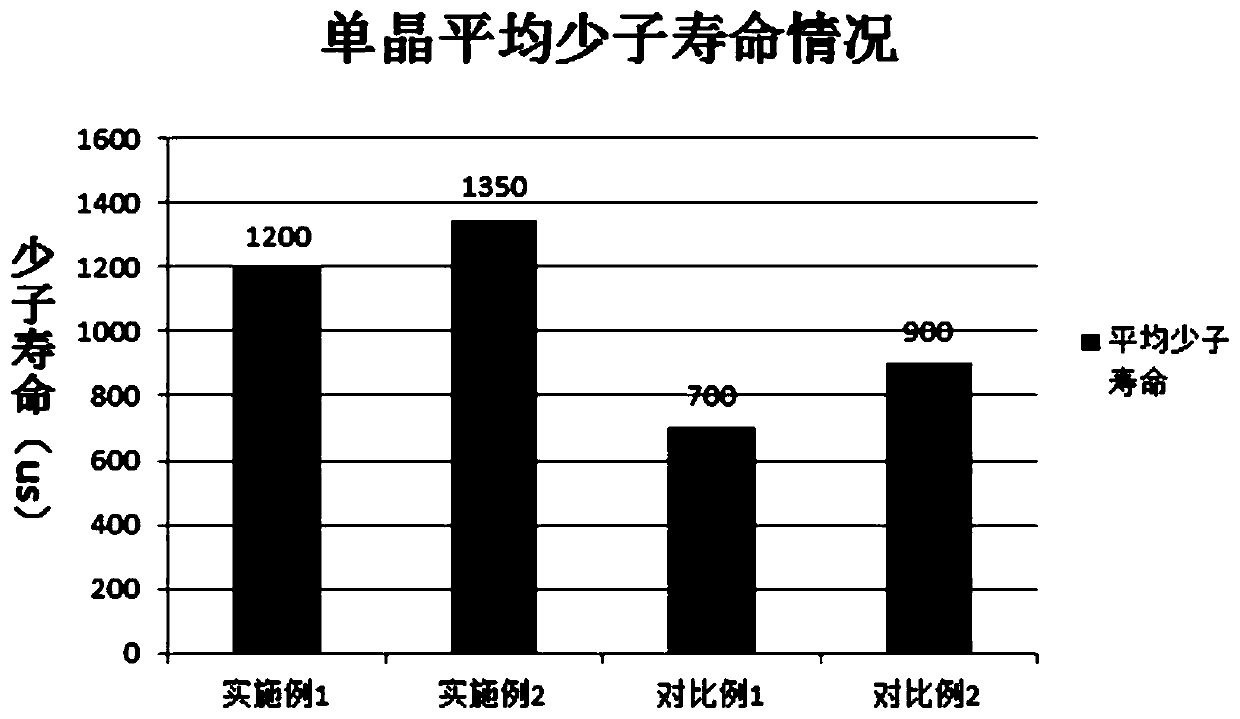

An annealing method for recovering the true resistivity of ntd zone molten single crystal silicon

A single crystal silicon and resistivity technology, applied in chemical instruments and methods, crystal growth, after treatment, etc., can solve the problems of unstable resistivity and low lifetime of minority carriers, and achieve the effect of good resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Put the zone-melted single crystal silicon doped by neutron irradiation into the pickling solution (the volume ratio is HF:HNO 3 =1:6), pickling for 5 minutes, then rinsed with deionized water for 3 times, and dried;

[0031] 2. Put the cleaned single crystal silicon into the prepared passivation agent (ethanol solution of phosphorus pentoxide, the mass concentration is 5g / L), passivate for 5min, and then dry the single crystal;

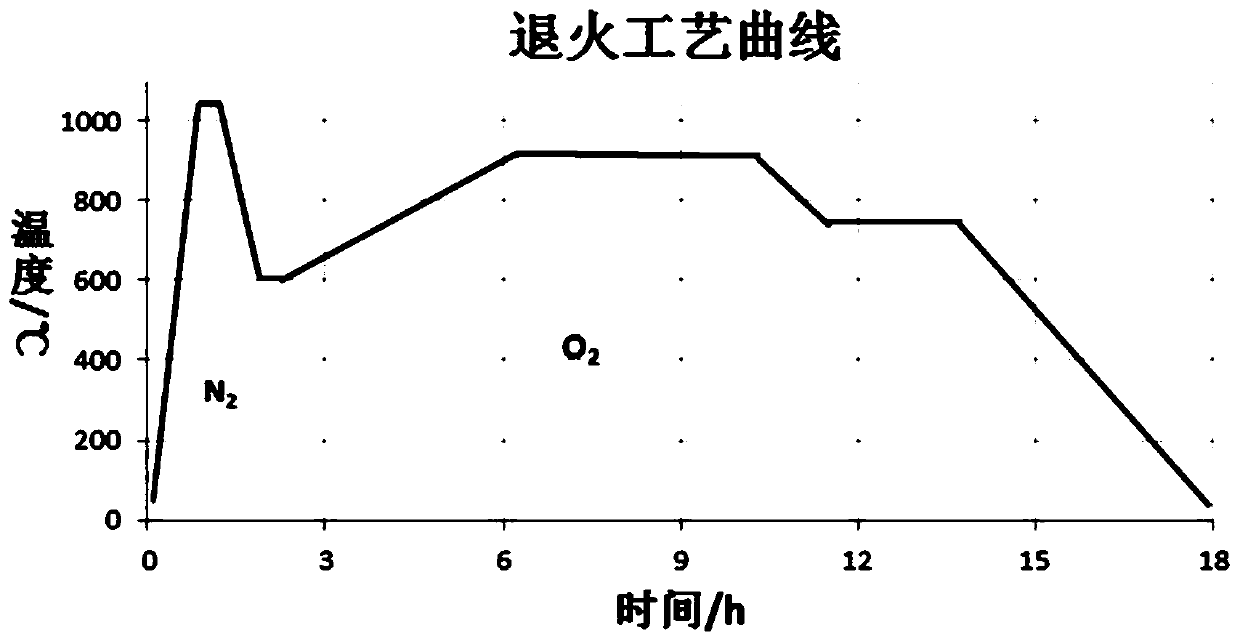

[0032] 3. Put the passivated silicon single crystal into the quartz tube of the annealing furnace fed with nitrogen (the flow rate of nitrogen is 4L / min), heat up from room temperature to 1000°C at a rate of 20°C / min, keep it warm for 2mim, and then Cool down to 550°C at a rate of 20°C, close the nitrogen flow valve, and keep warm for 5 minutes;

[0033] 4. Open the oxygen flow valve, control the flow at 2L / min, raise the temperature from 550°C to 800°C at a rate of 4°C / min, and keep warm for 3 hours; then cool down from 800°C to 700°C at ...

Embodiment 2

[0036] 1. Put the zone-melted single crystal silicon doped by neutron irradiation into the pickling solution (the volume ratio is HF:HNO 3 =1:6), pickling for 5 minutes, then rinsed with deionized water for 3 times, and dried;

[0037] 2. Put the cleaned single crystal silicon into the prepared passivation agent (ethanol solution of phosphorus pentoxide, the mass concentration is 5g / L), passivate for 5min, and then dry the single crystal;

[0038] 3. Put the passivated silicon single crystal into the quartz tube of the annealing furnace fed with nitrogen (the flow rate of nitrogen is 6L / min), raise the temperature from room temperature to 1100°C at a rate of 25°C / min, keep it warm for 5mim, and then Cool down to 650°C at a rate of 25°C, close the nitrogen flow valve, and keep warm for 10 minutes;

[0039] 4. Open the oxygen flow valve, control the flow at 4L / min, raise the temperature from 650°C to 900°C at a rate of 3°C / min, and keep it for 5 hours; then cool it down from 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com