Annealing method capable of recovering real resistivity of NTD (neutron transmutation doping) zone-melting monocrystalline silicon

A single crystal silicon, resistivity technology, applied in chemical instruments and methods, crystal growth, post-processing, etc., can solve the problems of unstable resistivity, low minority carrier lifetime, etc., and achieve good resistivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

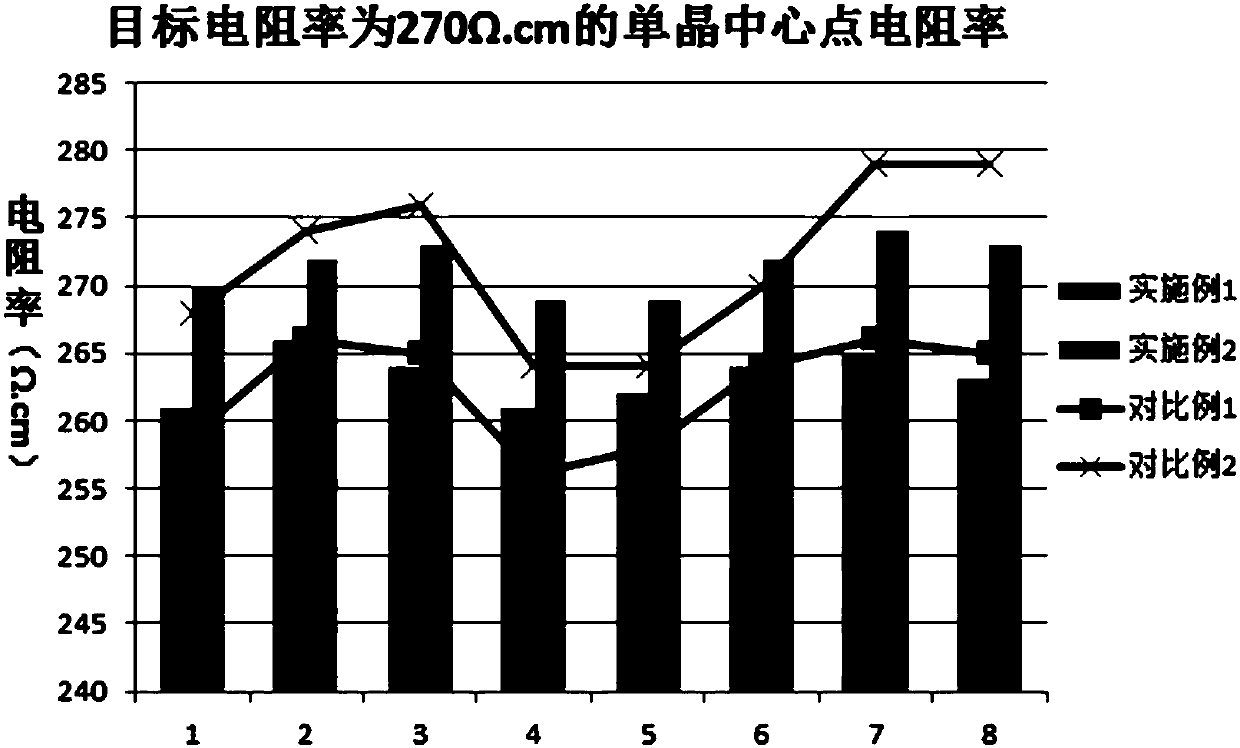

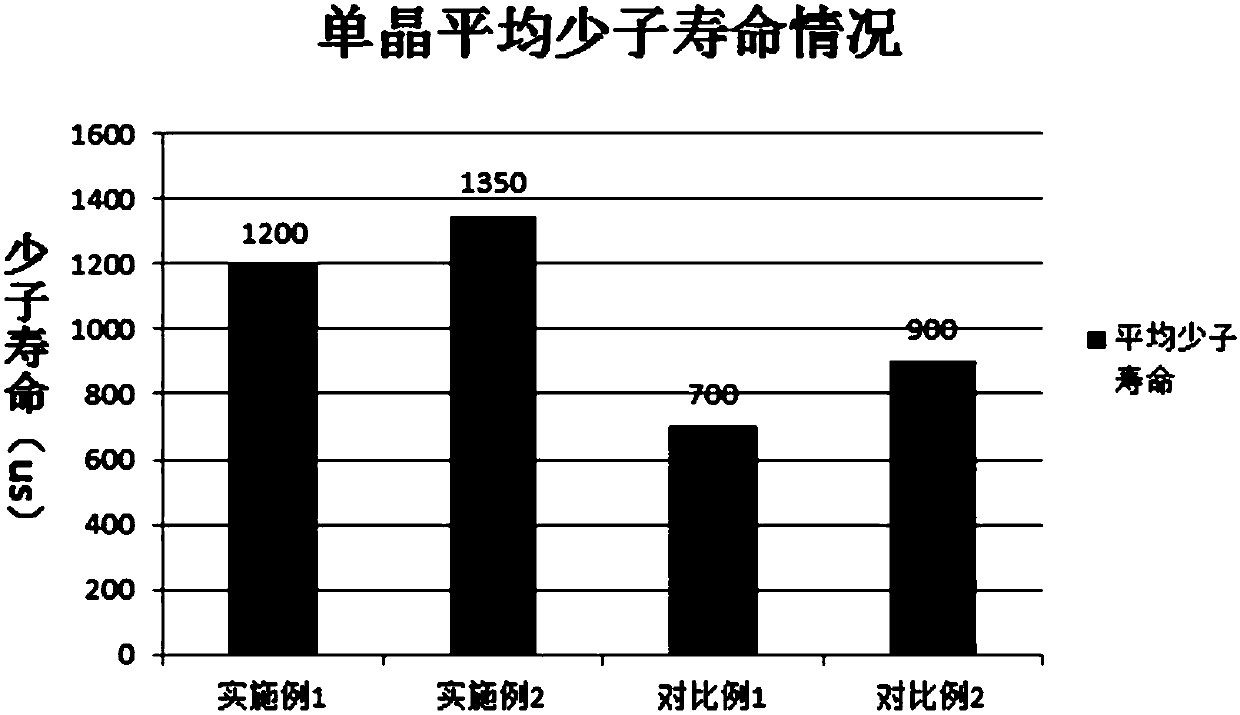

Embodiment 1

[0030] 1. Put the zone-melted single crystal silicon doped by neutron irradiation into the pickling solution (the volume ratio is HF:HNO 3 =1:6), pickling for 5 minutes, then rinsed with deionized water for 3 times, and dried;

[0031] 2. Put the cleaned single crystal silicon into the prepared passivation agent (ethanol solution of phosphorus pentoxide, the mass concentration is 5g / L), passivate for 5min, and then dry the single crystal;

[0032] 3. Put the passivated silicon single crystal into the quartz tube of the annealing furnace fed with nitrogen (the flow rate of nitrogen is 4L / min), heat up from room temperature to 1000°C at a rate of 20°C / min, keep it warm for 2mim, and then Cool down to 550°C at a rate of 20°C, close the nitrogen flow valve, and keep warm for 5 minutes;

[0033] 4. Open the oxygen flow valve, control the flow at 2L / min, raise the temperature from 550°C to 800°C at a rate of 4°C / min, and keep warm for 3 hours; then cool down from 800°C to 700°C at ...

Embodiment 2

[0036] 1. Put the zone-melted single crystal silicon doped by neutron irradiation into the pickling solution (the volume ratio is HF:HNO 3 =1:6), pickling for 5 minutes, then rinsed with deionized water for 3 times, and dried;

[0037] 2. Put the cleaned single crystal silicon into the prepared passivation agent (ethanol solution of phosphorus pentoxide, the mass concentration is 5g / L), passivate for 5min, and then dry the single crystal;

[0038] 3. Put the passivated silicon single crystal into the quartz tube of the annealing furnace fed with nitrogen (the flow rate of nitrogen is 6L / min), raise the temperature from room temperature to 1100°C at a rate of 25°C / min, keep it warm for 5mim, and then Cool down to 650°C at a rate of 25°C, close the nitrogen flow valve, and keep warm for 10 minutes;

[0039] 4. Open the oxygen flow valve, control the flow at 4L / min, raise the temperature from 650°C to 900°C at a rate of 3°C / min, and keep it for 5 hours; then cool it down from 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com