Method for preparing flame-retardant smoke inhibition polypropylene

A polypropylene and polypropylene material technology, applied in the field of preparation of flame-retardant and smoke-suppressing polypropylene, can solve the problems of poor flame-retardant performance, easy aging, poor low-temperature impact resistance, etc. Emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

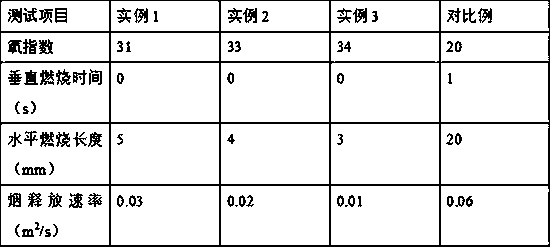

Examples

example 1

[0024]Weigh 200g of sepiolite, place it in a stone grinder and grind for 2h, pass through a 100-mesh sieve to obtain sepiolite powder, add 400mL of phosphoric acid solution with a mass fraction of 40% in the plastic basin, pour the sepiolite powder into the plastic basin, Stir for 40 minutes to obtain a sepiolite suspension, pass 10L of ammonia gas into the sepiolite suspension to obtain a flame-retardant mother liquor; weigh 40g of β-cyclodextrin, 12g of sodium hydroxide and 200mL of distilled water into a four-necked flask, Heat the four-neck flask in a water bath to 80°C, start the stirrer, stir and mix at a speed of 300r / min for 30min, and fill 70mL of dimethyl sulfoxide solution of E-51 epoxy resin with a mass fraction of 30% into a constant Pressure dropping funnel, use the constant pressure dropping funnel to drip the dimethyl sulfoxide solution of E-51 type epoxy resin to the four-necked flask with a dropping rate of 5mL / min, keep the temperature for 6h, and obtain the ...

example 2

[0026] Weigh 250g of sepiolite, place it in a stone grinder and grind for 2.5 hours, pass through a 100-mesh sieve to obtain sepiolite powder, add 450mL of phosphoric acid solution with a mass fraction of 40% to the plastic basin, and pour the sepiolite powder into the plastic basin , stirred for 45 minutes to obtain a sepiolite suspension, and 12L of ammonia gas was passed into the sepiolite suspension to obtain a flame-retardant mother liquor; weigh 45g of β-cyclodextrin, 14g of sodium hydroxide and 250mL of distilled water into a four-neck flask , heat the four-necked flask in a water bath to 85°C, start the agitator, stir and mix at a speed of 320r / min for 35min, and put 75mL of dimethyl sulfoxide solution of E-51 epoxy resin with a mass fraction of 30% into Constant pressure dropping funnel, drop the dimethyl sulfoxide solution of E-51 type epoxy resin to the four-necked flask with the constant pressure dropping funnel at a dropping rate of 8mL / min, keep the temperature fo...

example 3

[0028] Weigh 300g of sepiolite, place it in a stone grinder and grind for 3 hours, pass through a 100-mesh sieve to obtain sepiolite powder, add 500mL of phosphoric acid solution with a mass fraction of 40% in the plastic basin, pour the sepiolite powder into the plastic basin, Stir for 50 minutes to obtain a sepiolite suspension, inject 15L of ammonia gas into the sepiolite suspension to obtain a flame-retardant mother liquor; weigh 50g of β-cyclodextrin, 15g of sodium hydroxide and 300mL of distilled water into a four-necked flask, Heat the four-neck flask in a water bath to 90°C, start the stirrer, stir and mix at a speed of 350r / min for 40min, and fill 80mL of dimethyl sulfoxide solution of E-51 epoxy resin with a mass fraction of 30% into a constant Pressure dropping funnel, use the constant pressure dropping funnel to drip the dimethyl sulfoxide solution of E-51 type epoxy resin to the four-necked flask at a dropping rate of 10mL / min, keep the temperature for 8h, and obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com