A kind of preparation method of cast iron cylinder liner based on inner surface coating

An inner surface and coating technology, applied in coating, casting molding equipment, metal material coating process, etc., can solve the difficulty of meeting the requirements of cylinder liner strength, wear resistance and cost, high production cost of cylinder liner, running-in Long time and other problems, to achieve the effect of low manufacturing cost, convenient processing and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

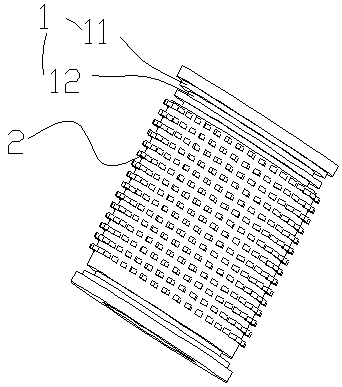

Image

Examples

Embodiment 1

[0032] 1) 100 parts by mass of silicon micropowder with a particle size of 325-400 mesh, 25 parts by mass of sodium bentonite with a particle size of 325-400 mesh, 23 parts by mass of high-alumina bauxite with a particle size of 325-400 mesh, and 1.1 parts by mass of Add sodium stearate, 33 parts by mass and benzoxazine resin with a particle size of 325 to 400 meshes, and 1.2 parts by mass of copper chloride in the wheel-type sand mixer, and mix and grind for 25 minutes; pour the rolled material into After adding 200 parts by mass of water into the mixing tank, the mixture was stirred at a speed of 200 rpm for 3 hours to prepare the coating.

[0033] 2) Dosing according to the following chemical composition percentage: C: 3.0%~3.2%, Si: 2.5%~3.0%, S: ≤0.1%, P: ≤0.2%, Cr: 0.5%~0.6%, Ni : 0.1%~0.2%, Mo: 0.2%~0.3%, Cu: 0.4%~0.5%, Ti: ≤0.03%, rare earth ferrosilicon alloy inoculant: 0.8%, the rest is Fe, pour the above ingredients into the medium frequency induction furnace Melti...

Embodiment 2

[0039] 1) 100 parts by mass of silicon micropowder with a particle size of 325-400 mesh, 28 parts by mass of sodium bentonite with a particle size of 325-400 mesh, 25 parts by mass of high-alumina bauxite with a particle size of 325-400 mesh, and 1.2 parts by mass of Add sodium stearate, 35 parts by mass of benzoxazine resin with a particle size of 325 to 400 meshes, and 1.2 parts by mass of copper chloride in a wheel-type sand mixer, and mix and grind for 30 minutes; pour the rolled material into After adding 210 parts by mass of water into the mixing tank, the mixture was stirred at a speed of 220 rpm for 3 hours to prepare the coating.

[0040] 2) Dosing according to the following chemical composition percentage: C: 3.0%~3.2%, Si: 2.5%~3.0%, S: ≤0.1%, P: ≤0.2%, Cr: 0.5%~0.6%, Ni : 0.1%~0.2%, Mo: 0.2%~0.3%, Cu: 0.4%~0.5%, Ti: ≤0.03%, rare earth ferrosilicon alloy inoculant: 0.8%, the rest is Fe, pour the above ingredients into the medium frequency induction furnace Melting ...

Embodiment 3

[0046] 1) 100 parts by mass of silica powder with a particle size of 325-400 mesh, 30 parts by mass of sodium bentonite with a particle size of 325-400 mesh, 25 parts by mass of high-alumina bauxite with a particle size of 325-400 mesh, and 1.2 parts by mass of Add sodium stearate, 35 parts by mass and benzoxazine resin with a particle size of 325 to 400 meshes, and 1.3 parts by mass of copper chloride in the wheel-type sand mixer, and mix and grind for 30 minutes; pour the rolled material into In the mixing bucket, after adding 220 parts by mass of water, the mixture was stirred at a speed of 230 rpm for 4 hours to prepare the coating.

[0047] 2) Dosing according to the following chemical composition percentage: C: 3.0%~3.2%, Si: 2.5%~3.0%, S: ≤0.1%, P: ≤0.2%, Cr: 0.5%~0.6%, Ni : 0.1%~0.2%, Mo: 0.2%~0.3%, Cu: 0.4%~0.5%, Ti: ≤0.03%, rare earth ferrosilicon alloy inoculant: 0.8%, the rest is Fe, pour the above ingredients into the medium frequency induction furnace Melting is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com