Bimetallic composite wire cross section transmission sample preparation method

A technology for sample preparation and bimetallic wire, applied in the direction of material analysis, measurement device, and instrument using wave/particle radiation, which can solve the problems of high preparation cost, strong dependence on proprietary equipment, and hindering research by scientific researchers. Achieve the effect of reducing preparation cost, reducing dependence and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

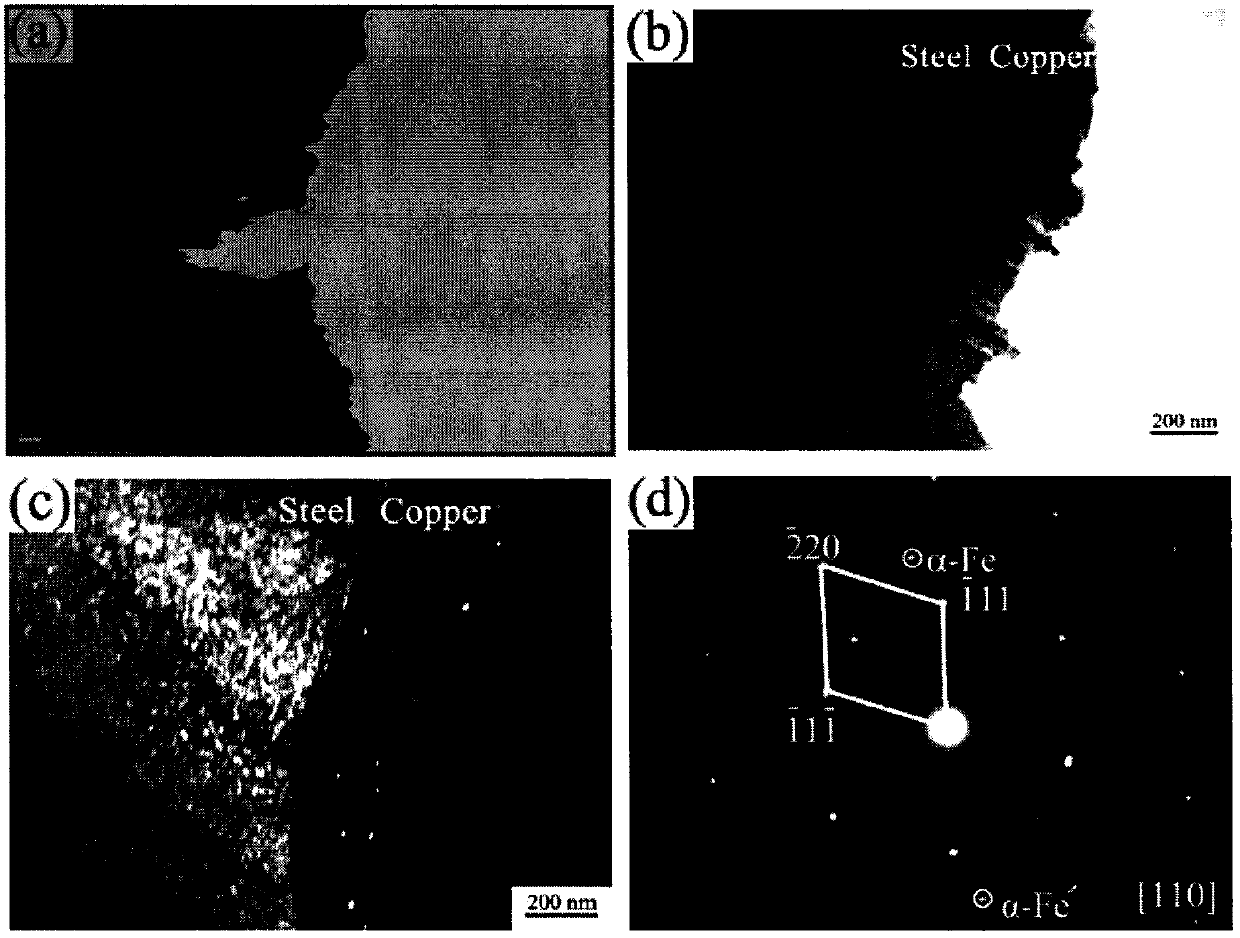

Image

Examples

Embodiment 1

[0022] A method for preparing a cross-sectional transmission sample of a bimetal composite wire, specifically comprising the following steps:

[0023] S1. The bimetallic wire is cut into 0.5mm thick round slices along the direction perpendicular to the drawing;

[0024] S2. After cleaning the circular slices with acetone and alcohol, in order to obtain the interface sample with the largest copper layer, use 502 glue to stick three circular slices closely to each other at the same time on a sample with a suitable size and a flat and smooth surface. on the stage to ensure the existence of a thin coating layer in the subsequent grinding and polishing process;

[0025] S3. Grind with water-grinding sandpaper and then mechanically polish to the mirror surface; then soak the polished sample circular slice sticking on the sample table with acetone, and use the same method to grind and polish the other side of the sample after cleaning with alcohol ;

[0026] S3. Finally, the sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com