Composite anode material, preparation method of composite anode material, anode plate and preparation method of anode plate

A composite anode and anode technology, applied in the field of electrochemistry, can solve the problems of short life, reduced cathode product yield, and porous deposition layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

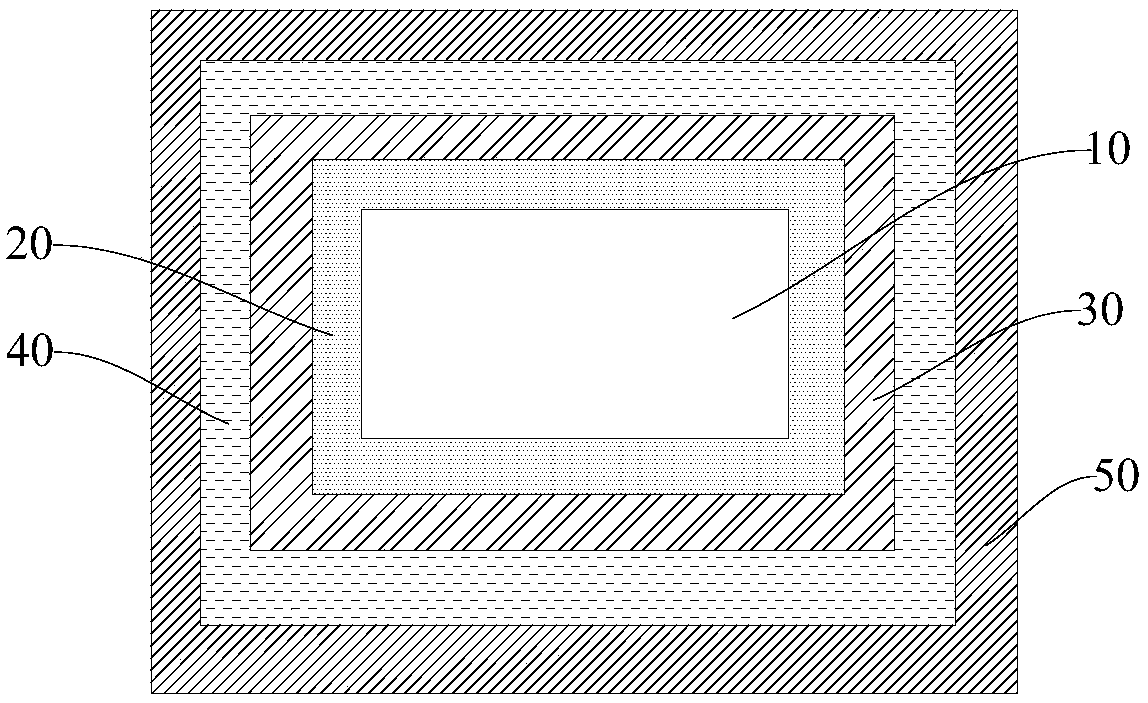

[0060] The present invention also provides a method for preparing the above-mentioned composite anode material, comprising: forming a metal layer outside the metal rod core; forming a conductive ceramic layer outside the metal layer by anode composite electrodeposition, and the conductive ceramic layer contains β- PbO 2 -A1 2 o 3 Composite oxide; an active ceramic layer is formed outside said conductive ceramic layer by anodic composite electrodeposition, said active ceramic layer comprising γ-MnO 2 -Ti 4 o 7 composite oxides.

[0061] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0062] According to the invention, said metal rod core is preferably formed by drawing extrusion techniques. The metal rod core is the same as described above, and will not be repeated here. The metal rod core formed by drawing and extrusion technology has a high degree of refinement of the aluminum alloy...

Embodiment 1

[0102] 1.1 Prepare a rectangular aluminum wire with a cross-section (the long axis of the cross-section is 10mm and the wide axis is 7mm) by drawing and extrusion process, and the surface is drawn with a corrugated pattern, and then the surface is sprayed with 300-mesh corundum , then placed in a mass ratio of 10% sodium hydroxide and soaked for 10 minutes, washed with water, and then placed in a mass ratio of 20% HNO 3 After 0.5min of immersion in the medium, wash with water, place the rod core after cleaning in sulfuric acid and carry out anodic oxidation treatment, obtain oxide film layer, wherein, anodic oxidation solution formula and process parameter comprise: 120g / L sulfuric acid (H 2 SO 4 ), 10g / L oxalic acid (H 2 C 2 o 4 ), 1g / L aluminum ion, 0.3g / L gelatin, the current density of the anode is 1A / dm 2 , the tank voltage is 18V, the temperature is 20°C, and the time is 40min; then the rod core after anodizing is placed in HC1 with a mass ratio of 20% and soaked for...

Embodiment 2

[0115] 2.1 The aluminum wire with a circular cross section (section diameter of 10mm) is prepared by drawing and extrusion process, and its surface is drawn with a corrugated pattern, and then its surface is sprayed with corundum with a particle size of 50 mesh, and then placed in a Soak in 10% sodium hydroxide for 10 minutes, wash with water, and place in 20% HNO 3 After 0.5min of immersion in the medium, wash with water, place the rod core after cleaning in sulfuric acid and carry out anodic oxidation treatment, obtain oxide film layer, wherein, anodic oxidation solution formula and process parameter comprise: 140g / L sulfuric acid (H 2 SO 4 ), 5g / L oxalic acid (H 2 C 2 o 4 ), 1g / L aluminum ion, 0.3g / L gelatin, the current density of the anode is 1A / dm 2, the tank voltage is 18V, the temperature is 20°C, and the time is 40min; then the rod core after anodizing is placed in HC1 with a mass ratio of 20% and soaked for 20min, washed with water, and then placed in silver salt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com