A kind of high-strength bolt material and its preparation method

A high-strength bolt and alloy composition technology, applied in the field of bolt materials, can solve the problems of low temper softening resistance of boron steel, high susceptibility to delayed fracture of bolts, and inability to meet the tensile strength, so as to achieve high yield and low Delayed Fracture Sensitivity, Effect of Improving Delayed Fracture Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Correspondingly, the present invention also provides a method for preparing the high-strength bolt material described in the above technical solution, comprising the following steps: smelting 42CrMo steel, ferro-titanium, ferro-vanadium, ferro-niobium and ferronickel in a vacuum induction furnace, casting A steel ingot is obtained; the steel ingot is heated to 1100-1300° C. for heat preservation, forged, and air-cooled to obtain a high-strength bolt material.

[0026] As a preferred solution, the mass of the steel ingot is 20kg. In the present invention, the steel ingot is heated to 1100-1300° C. for heat preservation, and the heat preservation time is preferably 1-4 hours; and the round rod with a diameter of 16 mm is preferably obtained by forging. In the step of obtaining high-strength bolt material, the final forging temperature is preferably 800-1000°C.

[0027] It can be seen from the above scheme that the present invention has the following advantages: the high-...

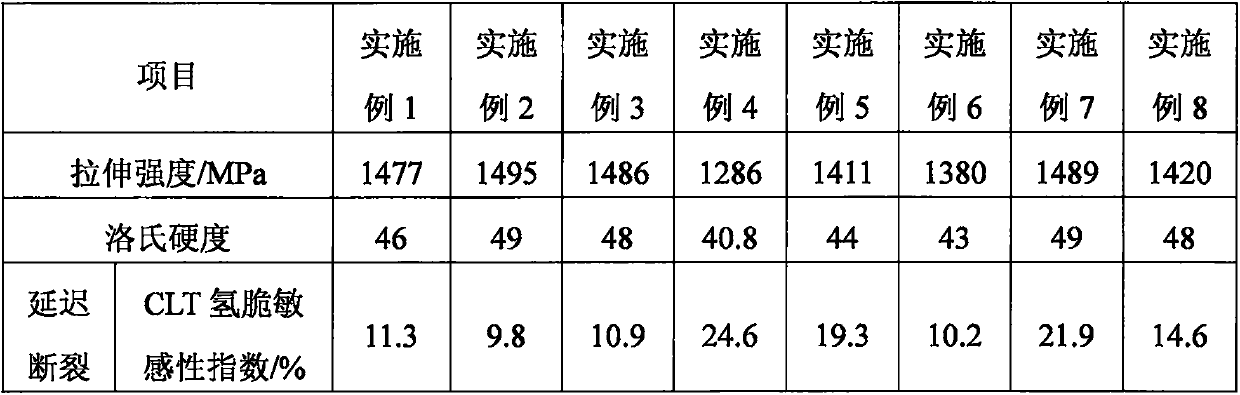

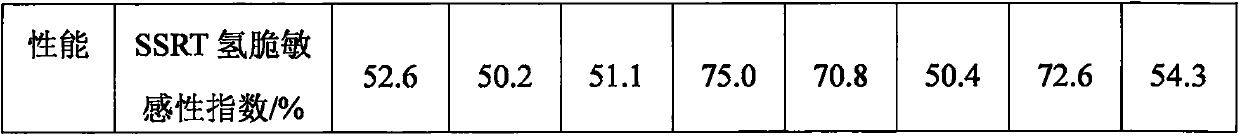

Embodiment 1

[0031] 42CrMo steel, ferro-titanium, ferro-vanadium, ferroniobium and ferronickel were smelted and poured into a 20kg ingot in a 250kg vacuum induction furnace, and then the ingot was heated to 1100°C for 4 hours and then forged into a round bar with a diameter of 16mm. The forging temperature is 800°C, air cooling after forging, to obtain high-strength bolt material, the weight percentage of each chemical composition is: C: 0.2%, Si: 0.2%, N: 0.004%, Mn: 0.4%, Cr: 1.5%, V : 0.02%, Ti: 0.02%, Mo: 0.3%, Nb: 0.02%, Ni: 0.5%, P: 0.004%, S: 0.003%, and the balance is Fe.

Embodiment 2

[0033]42CrMo steel, ferro-titanium, ferro-vanadium, ferro-niobium and ferronickel were smelted and poured into a 20-kg steel ingot in a 250-kg vacuum induction furnace. The forging temperature is 900°C, air cooling after forging, to obtain high-strength bolt material, the weight percentage of each chemical composition is: C: 0.4%, Si: 0.8%, N: 0.01%, Mn: 0.5%, Cr: 1.0%, V : 0.15%, Ti: 0.05%, Mo: 0.4%, Nb: 0.05%, Ni: 0.8%, P: 0.004%, S: 0.003%, and the balance is Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com