High strength bolt material and preparation method thereof

A high-strength bolt, weight percentage technology, applied in the field of bolt materials, can solve problems such as low economy, large limitations, and reduced bolt yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

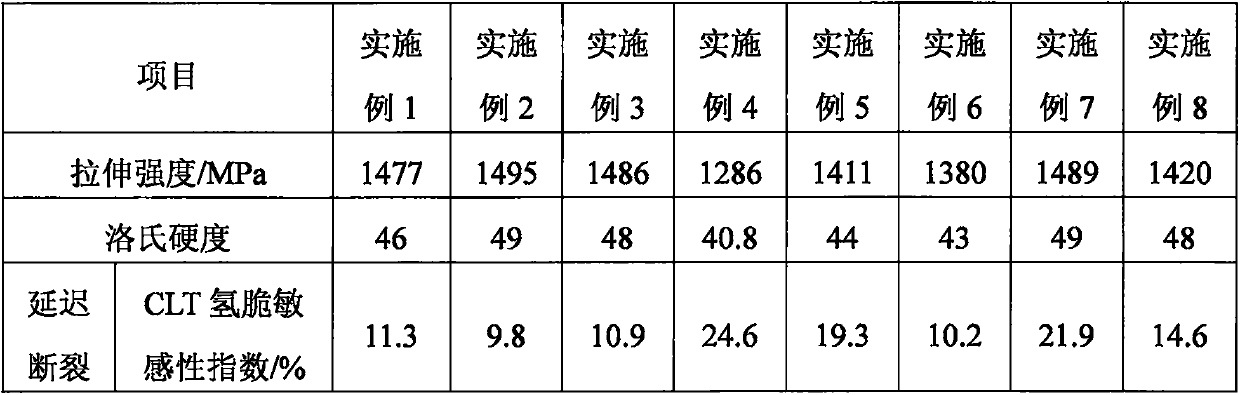

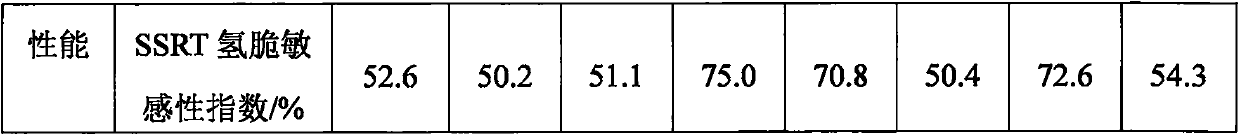

Examples

preparation example Construction

[0025] Correspondingly, the present invention also provides a method for preparing the high-strength bolt material described in the above technical solution, comprising the following steps: smelting 42CrMo steel, ferro-titanium, ferro-vanadium, ferro-niobium and ferronickel in a vacuum induction furnace, casting A steel ingot is obtained; the steel ingot is heated to 1100-1300° C. for heat preservation, forged, and air-cooled to obtain a high-strength bolt material.

[0026] As a preferred solution, the mass of the steel ingot is 20kg. In the present invention, the steel ingot is heated to 1100-1300° C. for heat preservation, and the heat preservation time is preferably 1-4 hours; and the round rod with a diameter of 16 mm is preferably obtained by forging. In the step of obtaining high-strength bolt material, the final forging temperature is preferably 800-1000°C.

[0027] It can be seen from the above scheme that the present invention has the following advantages: the high-...

Embodiment 1

[0031] 42CrMo steel, ferro-titanium, ferro-vanadium, ferroniobium and ferronickel were smelted and poured into a 20kg ingot in a 250kg vacuum induction furnace, and then the ingot was heated to 1100°C for 4 hours and then forged into a round bar with a diameter of 16mm. The forging temperature is 800°C, air cooling after forging to obtain high-strength bolt materials, the weight percentage of each chemical composition is: C: 0.2%, Si: 0.2%, N: 0.004%, Mn: 0.4%, Cr: 1.5%, V : 0.02%, Ti: 0.02%, Mo: 0.3%, Nb: 0.02%, Ni: 0.5%, P: 0.004%, S: 0.003%, and the balance is Fe.

Embodiment 2

[0033]42CrMo steel, ferro-titanium, ferro-vanadium, ferro-niobium and ferronickel were smelted and poured into a 20-kg steel ingot in a 250-kg vacuum induction furnace. The forging temperature is 900°C, air cooling after forging, to obtain high-strength bolt material, the weight percentage of each chemical composition is: C: 0.4%, Si: 0.8%, N: 0.01%, Mn: 0.5%, Cr: 1.0%, V : 0.15%, Ti: 0.05%, Mo: 0.4%, Nb: 0.05%, Ni: 0.8%, P: 0.004%, S: 0.003%, and the balance is Fe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com