Spongy symbiotic streptomyces and method and application thereof for producing staurosporine by fermentation

A staurosporine-sponge symbiosis technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of low yield, high fermentation cost, and low production of staurosporine, and achieve The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

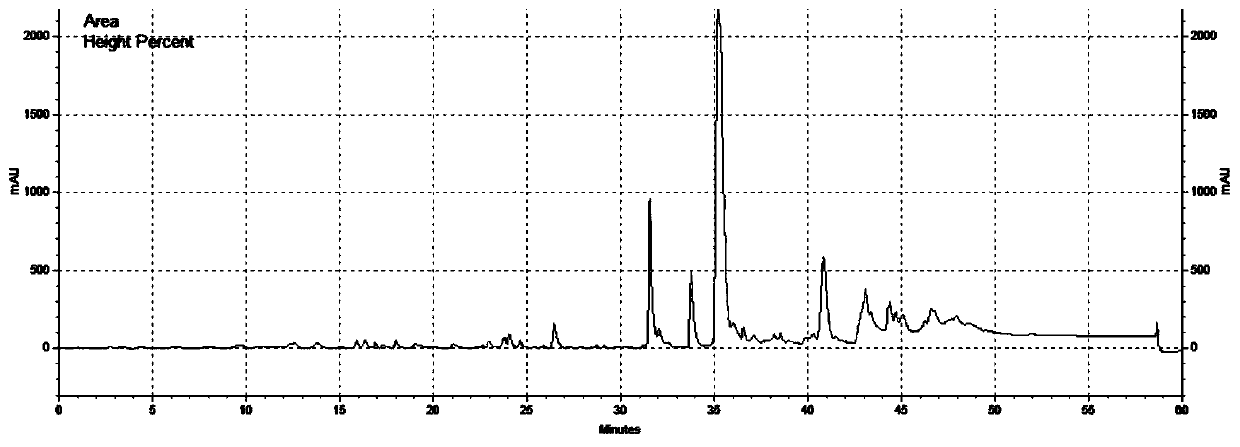

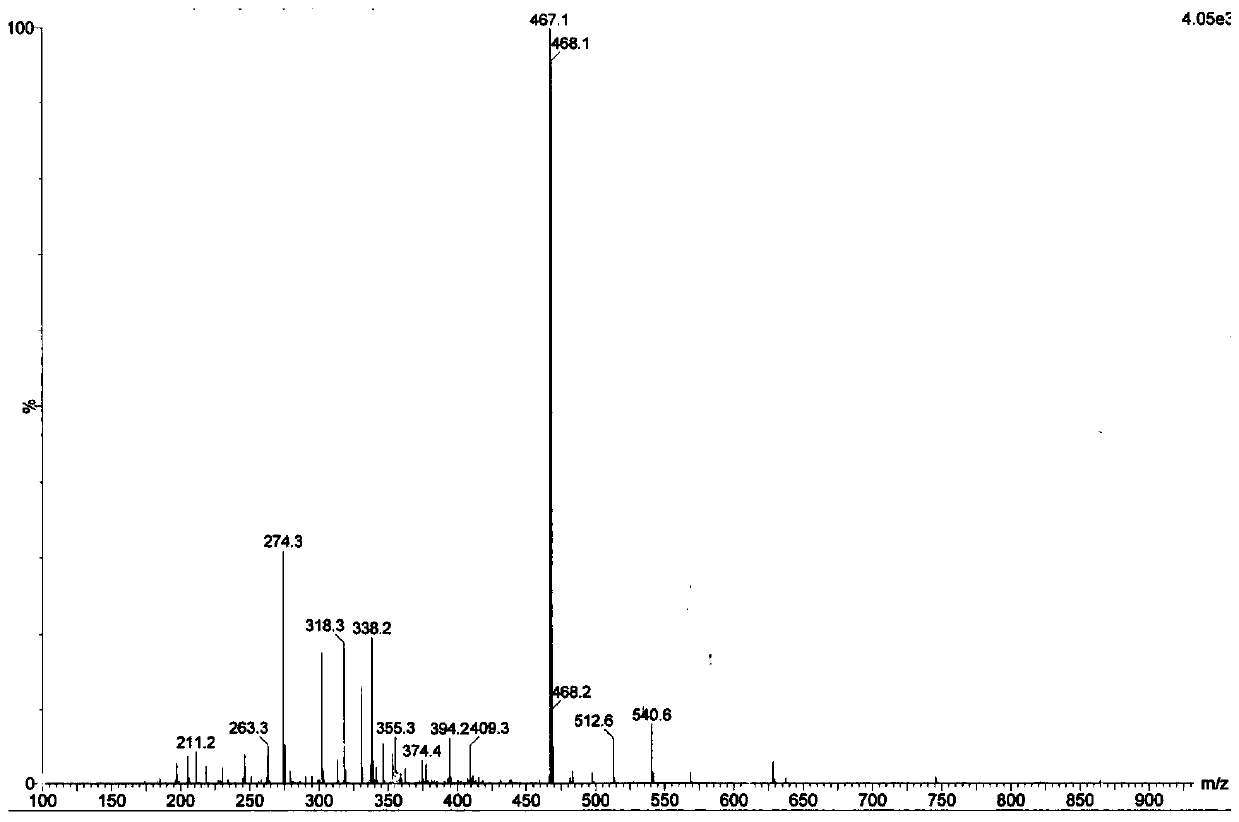

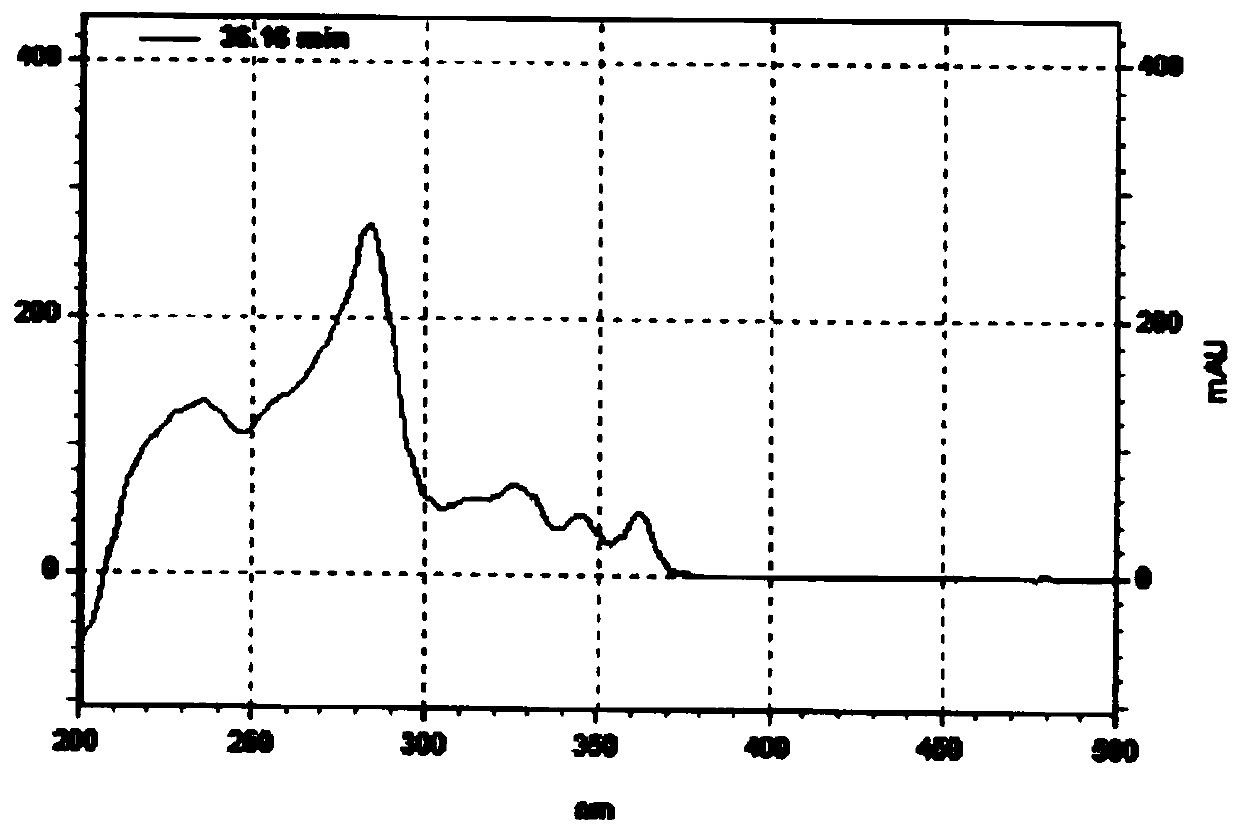

Image

Examples

Embodiment 1

[0052] Example 1 Isolation and Identification of Streptomyces (Streptomyces) SP6206

[0053] 1. Isolation of Streptomyces sp6206

[0054] The composition of strain isolation medium is as follows: soluble starch 10g, casein 0.3g, potassium nitrate 2g, magnesium sulfate heptahydrate 0.05g, sodium chloride 2g, dipotassium hydrogen phosphate 2g, calcium carbonate 0.02g, ferrous sulfate heptahydrate 0.01 g, potassium dichromate 0.1g, distilled water 500ml, aged sea water 500ml, agar 20g, pH 7.3.

[0055] Weigh 1g of sponge sample (collected from the sea area of Sanya, Hainan), grind it with 10ml of sterile seawater, then dilute it with sterile seawater 10 times, 100 times, 1000 times, absorb 100μl dilution respectively, and spread it on the separation medium plate , and cultured upside down in a constant temperature incubator at 28°C for 1 to 4 weeks. According to the morphological characteristics of the colonies on the plate, the actinomycete colonies on the plate were picked ...

Embodiment 2

[0058] Embodiment 2 uses Streptomyces sp6206 to produce staurosporine

[0059] The preparation method of the seed medium is as follows (pH value 7.5): 4g of yeast extract powder, 10g of malt extract powder, 4g of glucose, 500mL of aged sea water, and the remaining tap water to the volume of 1L. Sterilize at 121°C for 20 minutes.

[0060] The preparation method of the fermentation medium is as follows (pH value 9.0): 31.3g of soluble starch, 15g of soybean powder, 2g of yeast extract powder, 4g of calcium carbonate, 12.5g of HP-20 macroporous resin, 500ml of seawater, and the remaining tap water To IL. Sterilize at 121°C for 20 minutes.

[0061] 1. Strain fermentation

[0062] 1. Seed culture: Inoculate 100 ml of seed culture medium with Streptomyces sp6206. Cultivate at 28°C and 180 rpm for 96 hours to obtain a seed liquid.

[0063] 2. Fermentation culture: Fill 200ml fermentation medium in a 500ml Erlenmeyer flask. Inoculate 2ml of seed liquid in the culture medium, cul...

Embodiment 3

[0085]Embodiment 3 application Streptomyces SP6206 fermentation production staurosporine

[0086] The preparation method of the seed medium is as follows (pH7.5): 4g of yeast extract powder, 10g of malt extract powder, 4g of glucose, 500mL of aged sea water, and the remaining tap water to the volume of 1L. Sterilize at 121°C for 20 minutes.

[0087] The preparation method of the fermentation medium is as follows (pH9.0): 25.4g of soluble starch, 18g of soybean powder, 1.5g of yeast extract powder, 3g of calcium carbonate, 20.5g of HP-20 macroporous resin, 450ml of seawater, and the remaining tap water To IL. Sterilize at 121°C for 20 minutes.

[0088] 1. Strain fermentation

[0089] 1. Seed culture: Inoculate 100 ml of seed culture medium with Streptomyces sp6206. Cultivate at 28°C and 180 rpm for 96 hours to obtain a seed liquid.

[0090] 2. Fermentation culture: Fill 200ml fermentation medium in a 500ml Erlenmeyer flask. Inoculate 3 ml of seed solution in the culture m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com