Method for preparing porous tantalum medical implant material based on electron beam selective melting technology

A technology for selective melting and implantation of materials, which is applied in the fields of medical science, additive processing, and process efficiency improvement. Medical costs and surgical risks, achieving matching, and avoiding oxidation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment includes the following steps:

[0039] Step 1. Use MIMICS software to reconstruct the two-dimensional medical CT image to establish a three-dimensional rough model of porous tantalum medical implant material, and then use Pro / Engineer software and Magics software to sequentially perform the three-dimensional rough model of porous tantalum medical implant material Optimize and add to obtain a three-dimensional model of porous tantalum medical implant material, such as figure 1 Shown

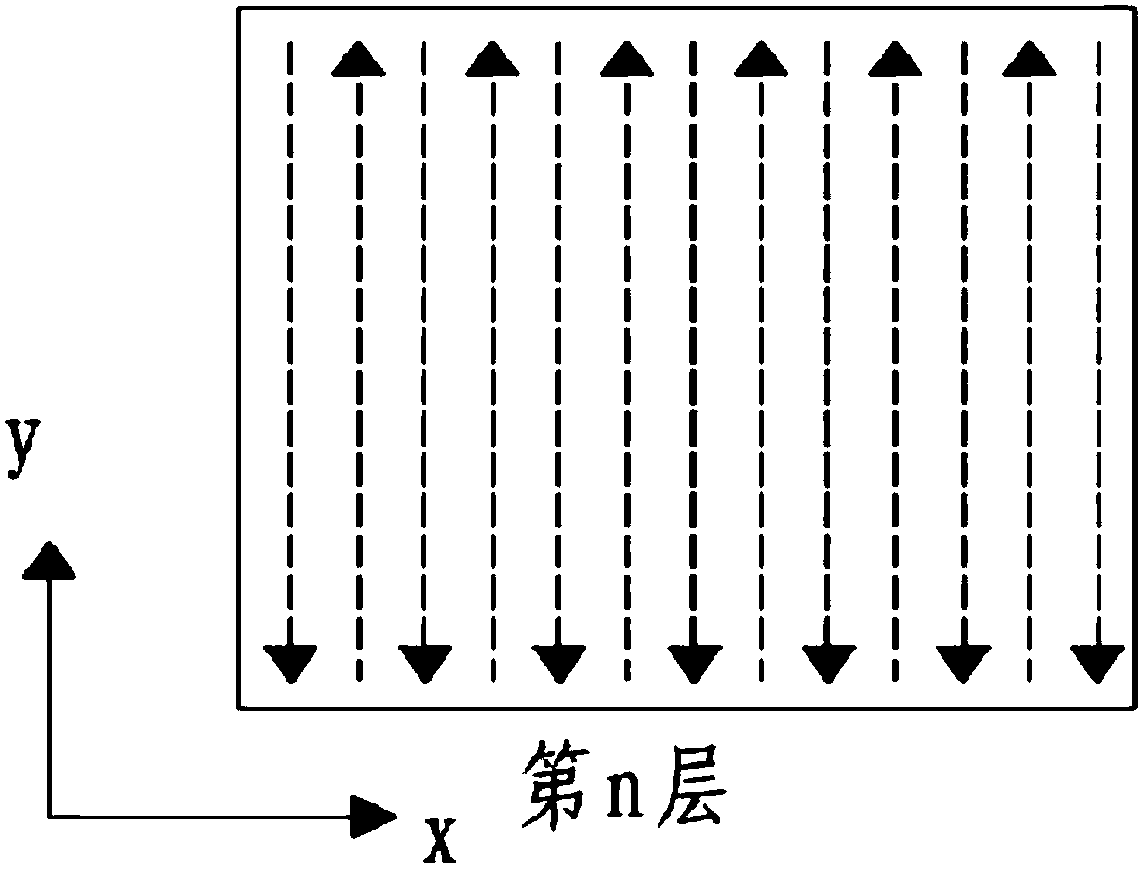

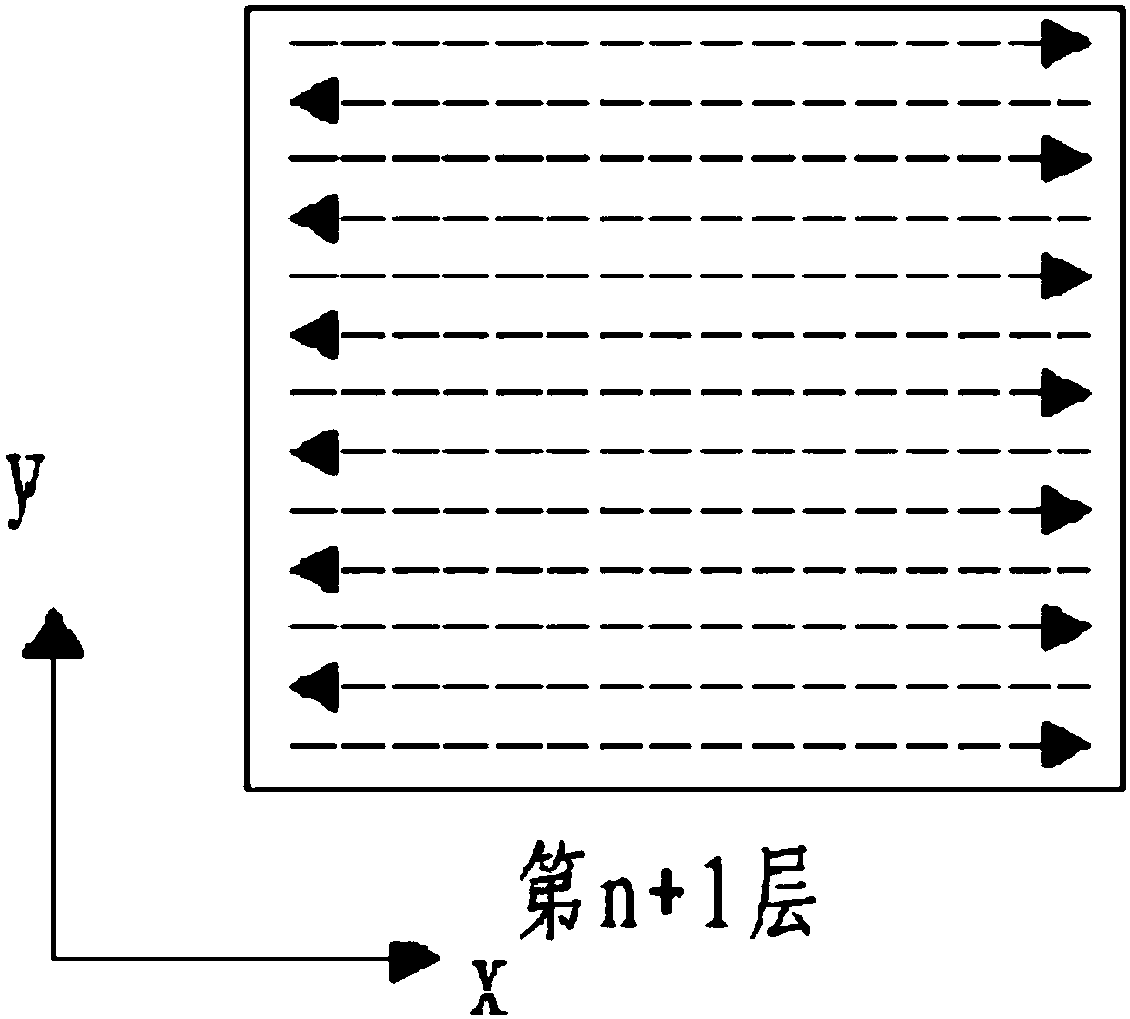

[0040] Step 2: Use AutoFab software to slice the three-dimensional model of the porous tantalum medical implant material obtained in step 1 to obtain slice data, and then store slice data in STL format and import it into the electron beam selective melting equipment; The thickness of each slice of slice processing is 90μm;

[0041] Step 3: Load the tantalum powder into the powder bin of the electron beam selective melting equipment, and vacuum the molding chamber of the electron b...

Embodiment 2

[0049] This embodiment includes the following steps:

[0050] Step 1. Use MIMICS software to reconstruct the MRI data, establish a three-dimensional rough model of porous tantalum medical implant material, and then use Pro / Engineer software and Magics software to optimize and add the three-dimensional rough model of porous tantalum medical implant material in turn To obtain a three-dimensional model of porous tantalum medical implant material;

[0051] Step 2: Use NetFabb software to slice the three-dimensional model of the porous tantalum medical implant material obtained in step 1 to obtain slice data, and then store slice data in AMF format and import it into the electron beam selective melting equipment; The thickness of each slice of slice processing is 60μm;

[0052] Step 3: Load the tantalum powder into the powder bin of the electron beam selective melting equipment, and evacuate the forming chamber of the electron beam selective melting equipment to a vacuum of 3.0×10 -3 Pa;...

Embodiment 3

[0059] This embodiment includes the following steps:

[0060] Step 1. Use MIMICS software to reconstruct the two-dimensional medical CT image, establish a three-dimensional rough model of porous tantalum medical implant material, and then use Solidworks software and Magics software to optimize and optimize the three-dimensional rough model of porous tantalum medical implant material. Add to obtain a three-dimensional model of porous tantalum medical implant material;

[0061] Step 2: Use Magics software to slice the three-dimensional model of the porous tantalum medical implant material obtained in step 1 to obtain slice data, and then store the slice data in AMF format and import it into the electron beam selective melting equipment; The thickness of each slice of slice processing is 20μm;

[0062] Step 3: Load the tantalum powder into the powder bin of the electron beam selective melting equipment, and vacuum the molding chamber of the electron beam selective melting equipment to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Powder size | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com