Iron and nickel-doped activated carbon-sulfur material and preparation method and application thereof

A technology of activated carbon and sulfur cathode material, applied in electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of difficult control of the reaction process, high cost of metal alkoxides, low specific capacity, etc., and improve the electrochemical cycle performance. , The effect of inhibiting negative electrode corrosion and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] A preparation method of iron, nickel doped activated carbon-sulfur cathode material, comprising the steps of:

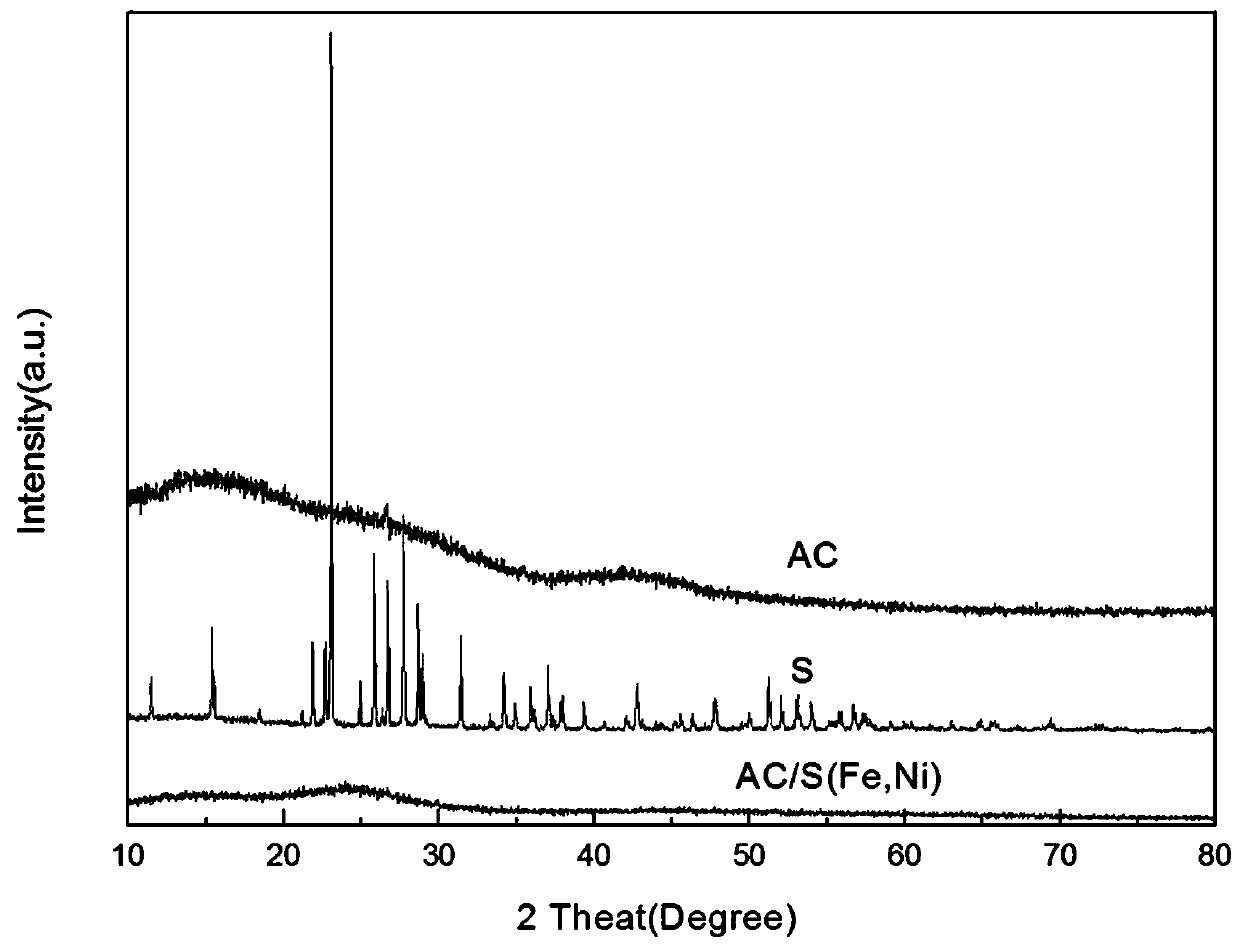

[0028] Step 1) Prepare iron and nickel doped activated carbon powder by hydrothermal method, and measure 8 mL 0.1 mol L respectively -1 Ni(NO 3 ) 2 , Fe(NO 3 ) 3 Solution and weigh 0.2 g of activated carbon into a beaker, then add 50 mL of N, N-dimethylformamide (DMF), ultrasonically disperse for 30 minutes to obtain a uniformly mixed solution, transfer it to a stainless steel reaction kettle, and heat at 160 °C Under the conditions, react for 20 h, cool to room temperature, wash with distilled water and organic solvent, and then dry to obtain iron and nickel doped activated carbon powder;

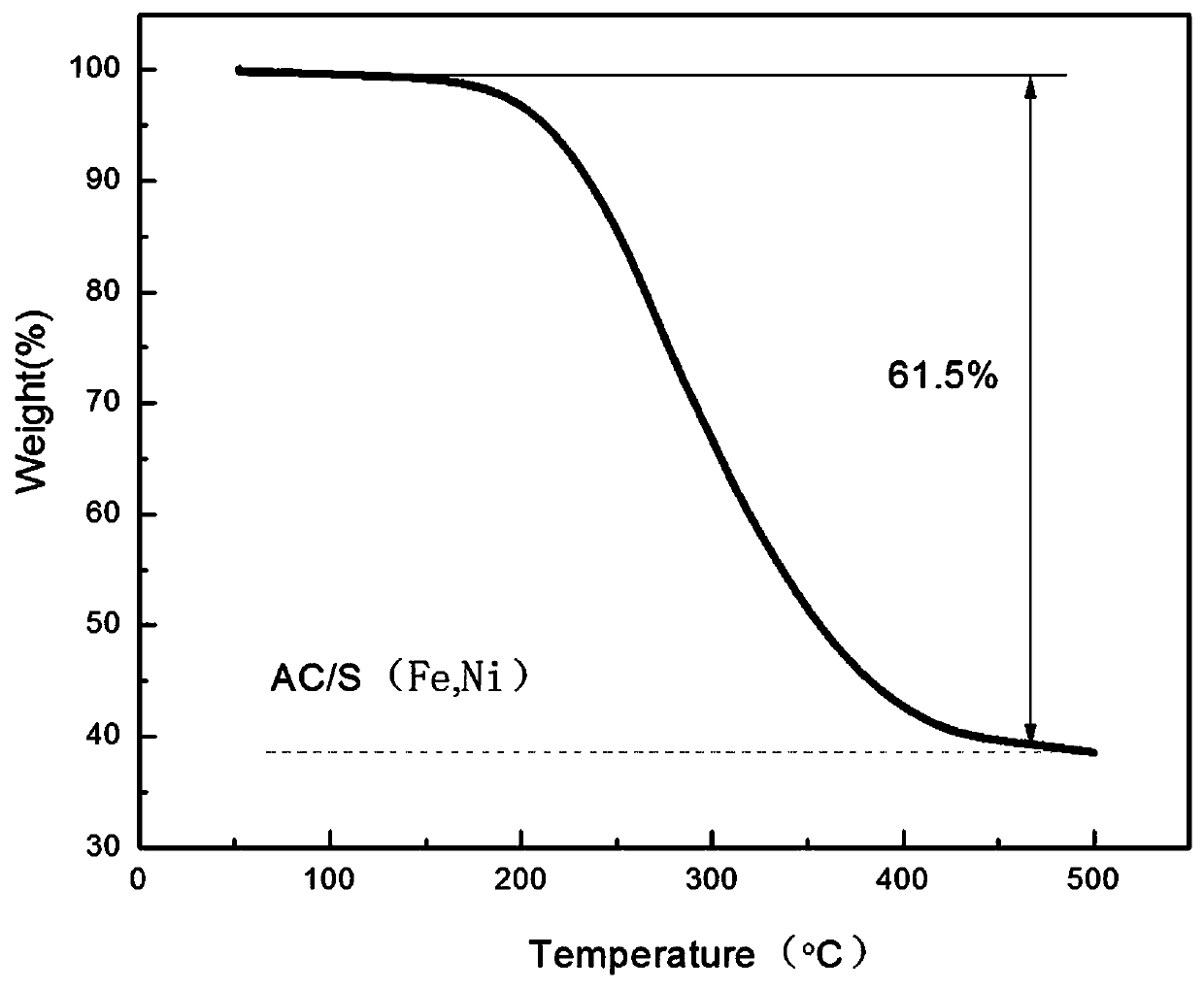

[0029] Step 2) The unactivated iron and nickel doped activated carbon-sulfur material was prepared by liquid phase in situ compounding method. 0.6 g of sublimed sulfur was dissolved in 200 mL of sodium sulfide aqueous solution, stirred thoroughly and ultrasonicated to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com