Device and method for inhibition of charge injection under transient electric field

A technology for suppressing transient and charge injection, applied to circuits, electrical components, conductor/cable insulation, etc., can solve problems such as flashover faults, electric field distortion aggravation, breakdown, etc., to suppress injection, improve insulation life, and improve The effect of starting voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An embodiment of the present invention provides a method for suppressing charge injection under a transient electric field, the method comprising the following steps:

[0024] Select a magnesium oxide target with a purity of 99.99% and put it into a magnetron sputtering apparatus, fix the substrate on the base of the magnetron sputtering apparatus for magnetron sputtering, and form a layer of magnesium oxide film on the surface of the substrate;

[0025] Insulate and cover the surface of the base body on the current-carrying module of the high-voltage equipment.

[0026] Before forming an insulating layer on the surface of the current-carrying part of the high-voltage equipment, the target material is a magnesium oxide target with a purity of 99.99%, and a layer of magnesium oxide film is formed on the surface of the substrate by magnetron sputtering coating or evaporation coating, and then, After the high-voltage equipment current-carrying module is insulated and cover...

Embodiment 2

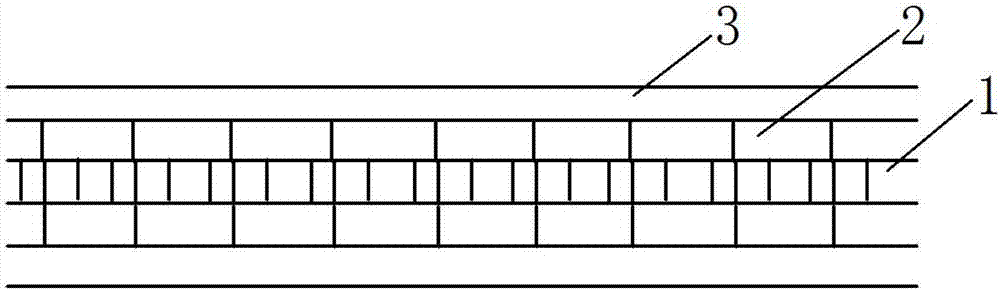

[0028] see figure 1 , an embodiment of the present invention provides a method for suppressing charge injection under a transient electric field, the method comprising the following steps:

[0029] Select a magnesium oxide target with a purity of 99.99% and put it into a magnetron sputtering apparatus, fix the substrate on the base of the magnetron sputtering apparatus for magnetron sputtering, and form a layer of magnesium oxide film on the surface of the substrate;

[0030] Insulate and cover the surface of the base body on the current-carrying module of the high-voltage equipment.

[0031] Optionally, the working mode of the magnetron sputtering apparatus is a pulse excitation source, the sputtering power is 300W, the sputtering chamber is evacuated to 0.35Pa, and high-purity argon gas is introduced into the chamber, and the gas flow rate is set to 35sccm, where sccm means standard milliliter per minute flow.

[0032] Optionally, the sputtering time of the magnetron sputt...

Embodiment 3

[0037] see figure 1 , An embodiment of the present invention provides a device for suppressing charge injection under a transient electric field, including the current-carrying module of a high-voltage equipment that has been insulated and covered according to any one of claims 1-5.

[0038] Optionally, the device includes a high-voltage motor provided with transformer winding insulation, a high-voltage circuit breaker provided with a combination switch and a gas-insulated metal pipe insulator, a medium-high voltage AC-DC bushing or a medium-high voltage AC-DC cable.

[0039]By magnetron sputtering coating or evaporation coating, a layer of magnesium oxide film with a thickness greater than 120nm is formed on the surface of the insulating material or metal conductor, and then, after the insulation covering of the high-voltage equipment current-carrying module module, it can be on the insulating material layer or A layer of dense magnesium oxide film is formed between the metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com