A method for high-purification preparation of nickel-based superalloy by electron beam melting technology

A nickel-based superalloy and electron beam smelting technology, which is applied in the field of high-purification nickel-based superalloys prepared by electron beam smelting technology, can solve the problems of severe solidification segregation, large shrinkage cavities, and poor surface quality of ingots, so as to improve metallurgical quality , Realize the effect of engineering preparation and shorten the time of process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

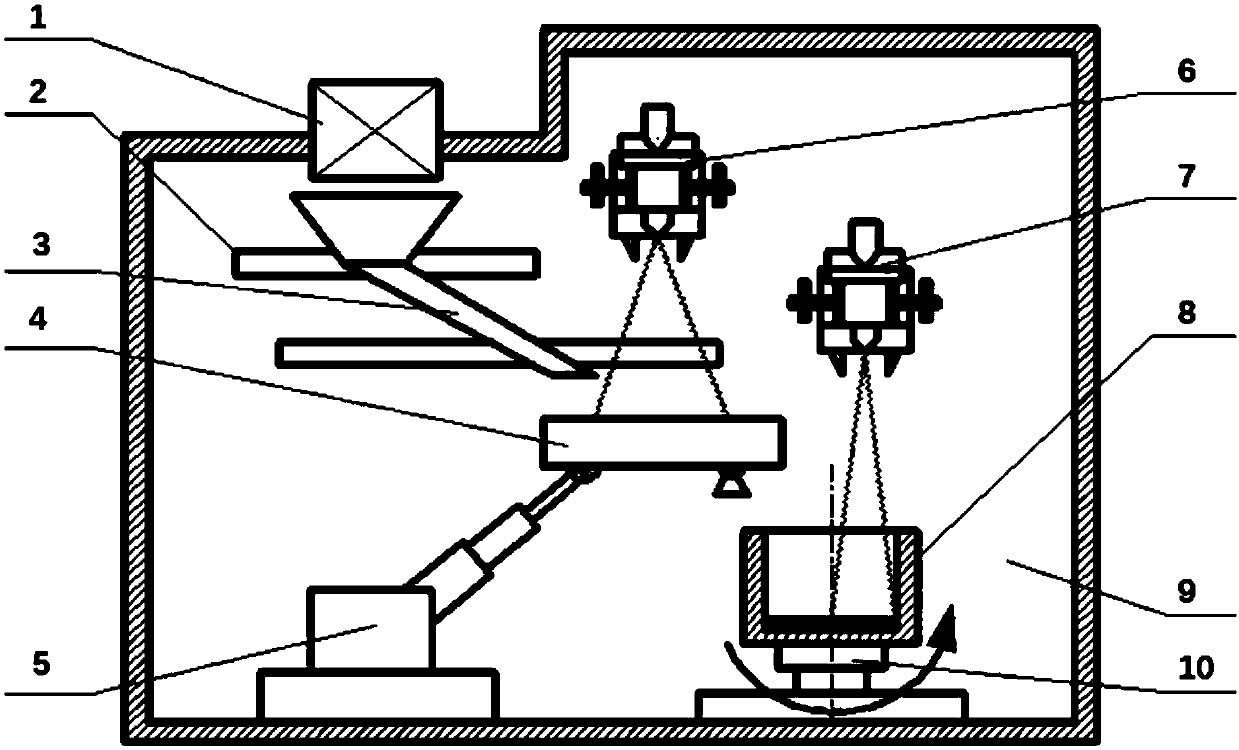

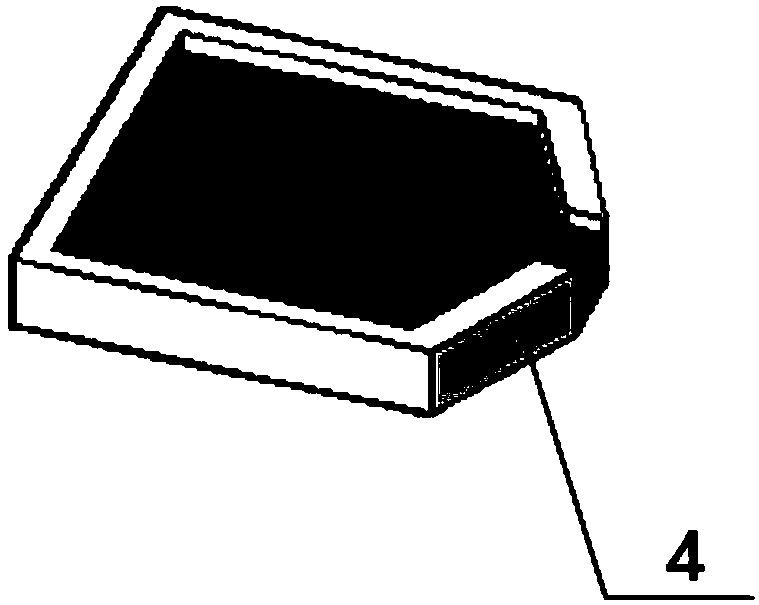

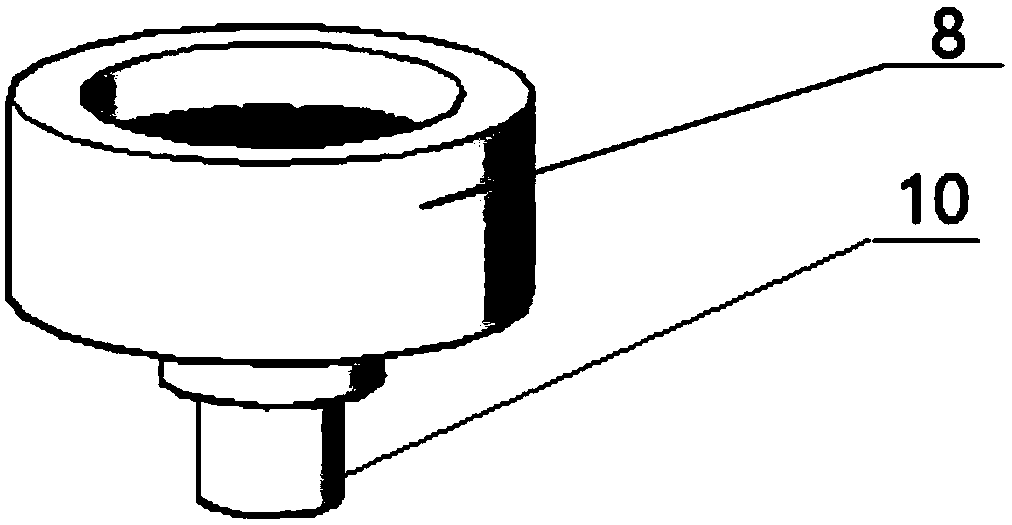

[0034] figure 1 It is a schematic diagram of equipment for a method of high-purification preparation of nickel-based superalloy by electron beam smelting technology. The equipment includes a feeding port 1, a feeding mechanism slide 2, a feeding mechanism 3, a refining water-cooled copper crucible 4, and a refining crucible lifting device 5. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com