Manufacturing technology of Wolter-I type precision core shaft

A manufacturing process and mandrel technology, which is applied in the field of machining Wolter-I type precision mandrels with 2-axis machine tools, can solve the problems of high manufacturing cost and difficult processing of high-precision Wolter-I type mandrels, etc., and improve the surface profile shape. The effect of precision, reduction of total machining allowance, and reduction of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

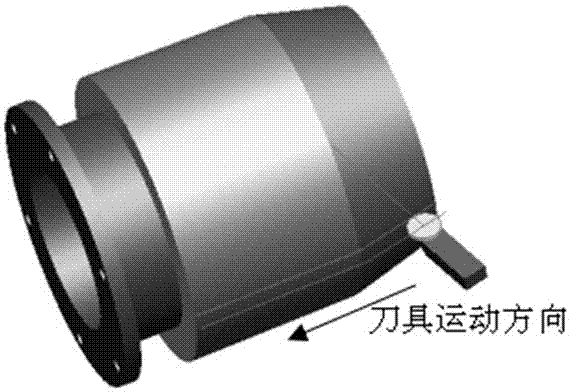

[0044] Taking the Woler-I mandrel composed of ellipsoidal surface and hyperboloid as an example for actual processing, it has undergone rough turning (measurement), electroless nickel-phosphorus alloy plating, fine turning (measurement), automatic polishing (measurement) and manual correction polishing. Manufactured with the largest caliber Φ The mandrel is 170.81mm, and the measured surface roughness of the sample is RMS1.56nm, which can meet the application requirements of extreme ultraviolet light with a wavelength below 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com