Chemiluminescence immunoassay based on labeling amplification of intelligent nano-luminescent particles and application of chemiluminescence immunoassay

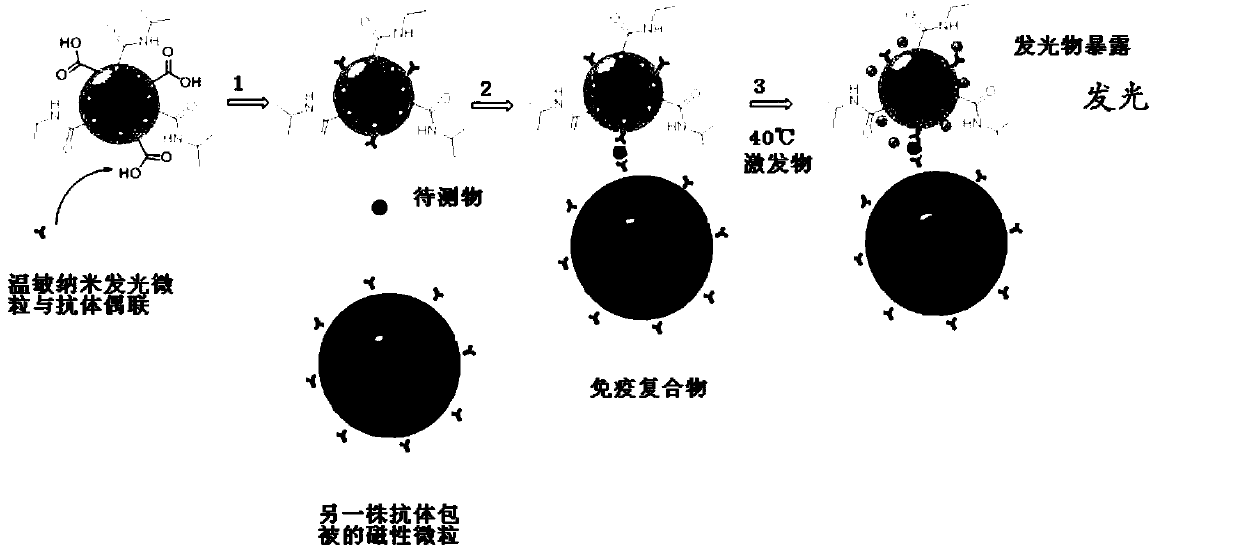

A technology of chemiluminescent immunity and luminescent particles, which is applied in the direction of analyzing materials through chemical reactions, chemiluminescence/bioluminescence, and analyzing materials. It can solve the problems of limited number of coupling functional groups, limited labeling amplification effect, and low labeling efficiency. To achieve high sensitivity, improve the labeling efficiency of luminescent molecules and antibodies, and wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of temperature-sensitive nano-luminescent particles:

[0036] Preparation of A.P(NIPAm-co-MAA) nanoparticles

[0037] Copolymerized nanoparticles (P(NIPAm-co-MAA)) of isopropylacrylamide and methacrylic acid were prepared by emulsion polymerization: 50 mg of sodium dodecyl sulfate (SDS) and 100 mg of peroxide were added to a three-necked flask. Potassium sulfate, add 100mL deionized water to dissolve. Take 2mL of monomer isopropylacrylamide, 0.1mL of methacrylic acid and 0.05mL of cross-linking agent methylenebisacrylamide (MBA), mix them uniformly in advance, add them into a three-necked flask, emulsify evenly and stir at 70°C The reaction was heated for 8 hours. After the product was collected, it was centrifuged (10,000 rpm, 30 min) to remove the liquid, and then resuspended with deionized water. This was repeated 3 times to obtain P(NIPAm-co-MAA) nanoparticles.

[0038] B. Preparation of P(NIPAm-co-MAA) Nanoparticles / Acridinium Ester Luminescent Co...

Embodiment 2

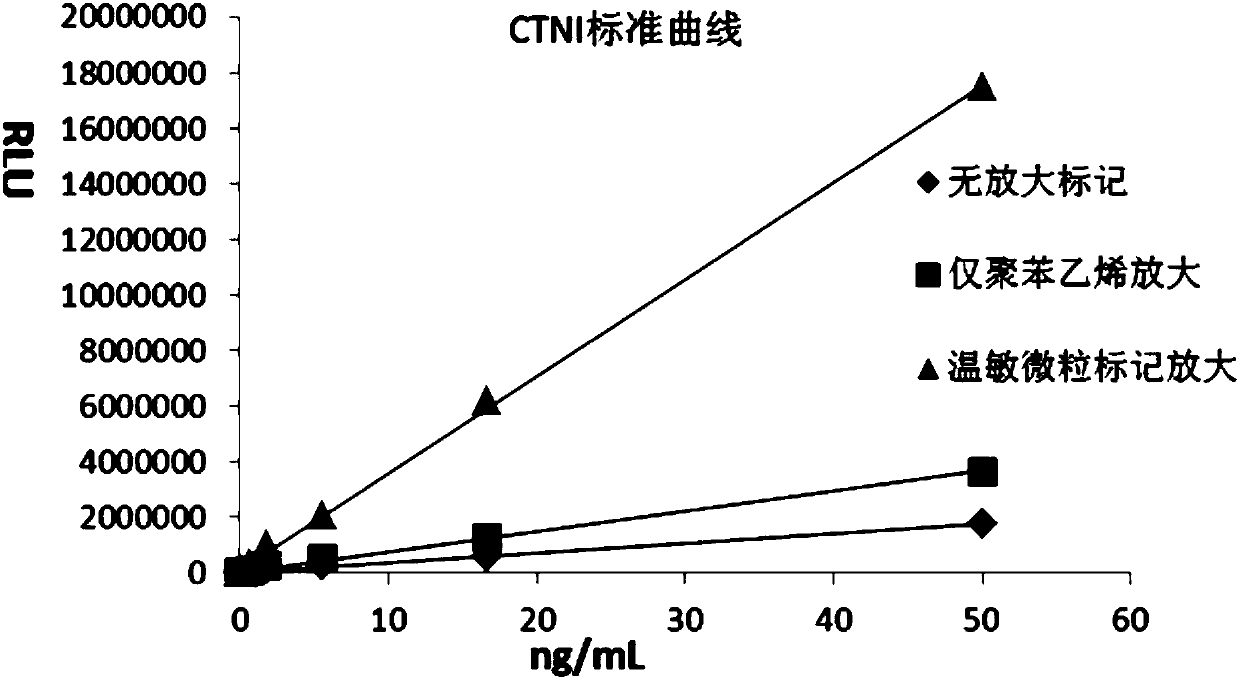

[0055] In order to confirm the significant advantages of the labeling amplification system based on temperature-sensitive nano-luminescent particles of the present invention, we designed the following parallel comparative experiments. The concentration gradient of the CTNI standard substance at the same concentration was detected with the traditional double-antibody sandwich system, the labeling amplification system only through polystyrene nanospheres, and the labeling amplification system of the present invention, and the luminescence value was recorded to fit the standard curve. The concentrations of CTNI detection antibodies used in the above three systems are equal.

[0056] A. Traditional CLIA double-antibody sandwich method:

[0057] Dilute with PBS buffer to prepare CTNI standard with concentration gradient 0, 0.003, 0.008, 0.023, 0.069, 0.206, 0.617, 1.852, 5.556, 16.667, 50.000ng / mL. In the cuvette, add 10 μL of streptavidin-coated magnetic microspheres, 50 μL of a ...

Embodiment 3

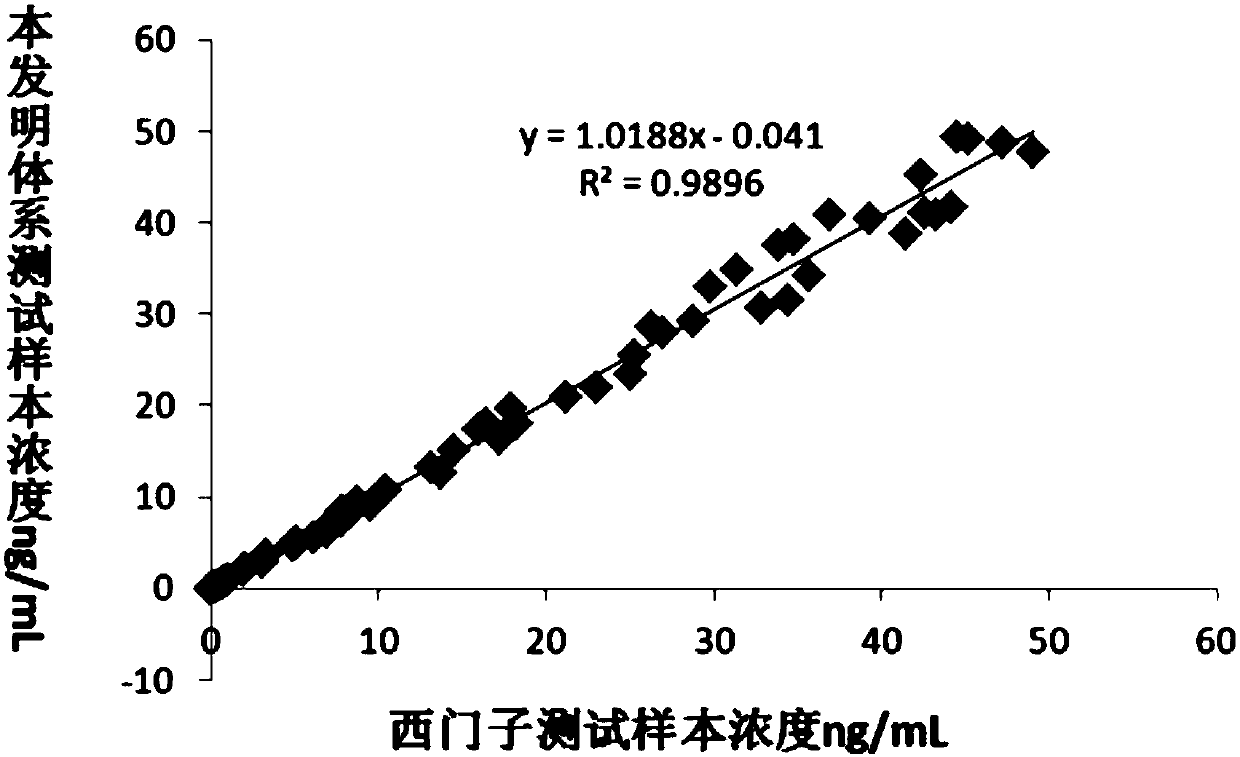

[0070] Embodiment 3 Correlation comparative experiment between the concentration of CTNI in the serum sample measured by the system test of the present invention and the measured value of Siemens

[0071] In order to verify the accuracy of the system kit of the present invention, after testing the CTNI content with Siemens CTNI chemiluminescent detection reagent for multiple serum samples, 60 samples with a suitable gradient were selected. Use the system of the present invention to measure the CTNI content respectively, and draw a graph to compare the correlation. Depend on image 3 It can be seen that the two systems show a good correlation, R 2 Values as high as 0.9896. It has been proved that the system of the present invention and the kit based on the system have excellent accuracy in addition to ultra-high sensitivity and wider detection range.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com