Modal interwoven fabric dyeing and finishing method

A technology for fabrics and dyeing machines, applied in dyeing methods, fabric surface trimming, two or more different solvent-based treatment materials, etc., can solve the problems of pilling, easy to pilling, falling, etc., to improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

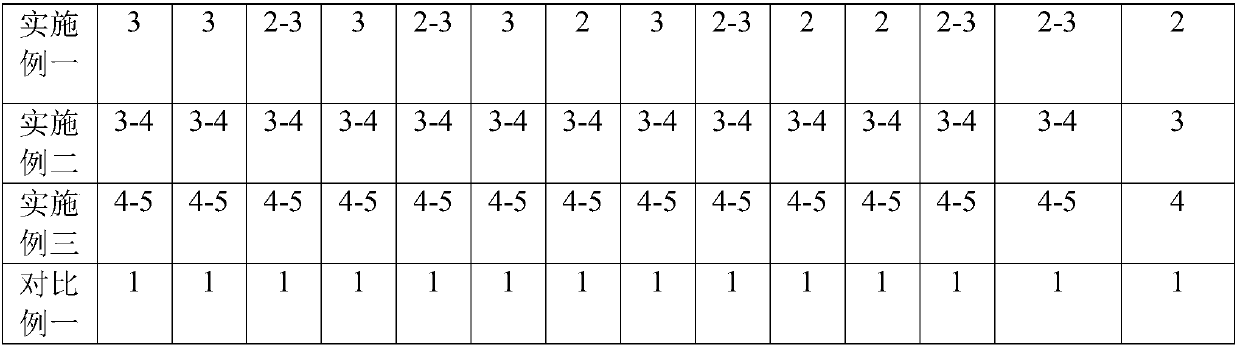

Embodiment 1

[0029] A method for dyeing and finishing modal interwoven fabrics, comprising the following steps:

[0030] Step (1) pre-treatment, mercerizing and washing the modal interwoven fabric through a mercerizing machine;

[0031] Step (2) pretreatment, put the mercerized woven fabric into the dyeing machine for fiber opening treatment, add 5-15g / L sulfuric acid acid additive or 5-15g / L soda ash into the dyeing machine Auxiliary;

[0032] Step (3) superfiber cutting, adding biological enzyme and palmitoyl chloride in the sand washing machine, preferably one or more of pectinase, protease and cellulase, the modal interwoven fabric after pretreatment is washed in sand Superfibrillation treatment is carried out in the machine, the concentration of biological enzyme is 1.2ml / L, the concentration of palmitoyl chloride is 0.3ml / L, the temperature is 50-70°C, and the processing time is 30-40min; the modal interweaving after superfiber cutting The fabric is put into the air-flow dyeing mac...

Embodiment 2

[0036] A method for dyeing and finishing modal interwoven fabrics, comprising the following steps:

[0037] Step (1) Impurity removal treatment, adding impurity removal aids to the rope washing machine, the impurity removal aids include 1-1.5g / L dispersing chelating agent, 0.2-0.3g / L hydrosulfite, 2-3g / L high-efficiency detergent and 5-10g / L sodium hypophosphite, the impurity removal treatment temperature is 80-85°C, and the time is 60-90min;

[0038] Step (2) pre-treatment, mercerizing and washing the modal interwoven fabric through a mercerizing machine;

[0039] Step (3) pretreatment, put the mercerized woven fabric into the dyeing machine for fiber opening treatment, add 5-15g / L sulfuric acid acid additive or 5-15g / L soda ash into the dyeing machine Auxiliary;

[0040] Step (4) superfiber cutting, adding bio-enzyme and palmitoyl chloride in the sand washing machine, preferably one or more of pectinase, protease and cellulase, the modal interwoven fabric after pretreatme...

Embodiment 3

[0044] A method for dyeing and finishing modal interwoven fabrics, comprising the following steps:

[0045] Step (1) Impurity removal treatment, adding impurity removal aids to the rope washing machine, the impurity removal aids include 1-1.5g / L dispersing chelating agent, 0.2-0.3g / L hydrosulfite, 2-3g / L high-efficiency detergent, the impurity removal treatment temperature is 80-85°C, and the time is 60-90min;

[0046] Step (2) pre-treatment, mercerizing and washing the modal interwoven fabric through a mercerizing machine;

[0047] Step (3) pretreatment, put the mercerized woven fabric into the dyeing machine for fiber opening treatment, add 5-15g / L sulfuric acid acid additive or 5-15g / L soda ash into the dyeing machine Auxiliary;

[0048] Step (4) superfiber cutting, adding bio-enzyme and palmitoyl chloride in the sand washing machine, preferably one or more of pectinase, protease and cellulase, the modal interwoven fabric after pretreatment is washed in sand Superfibril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com