Method for collecting platinum group metal through microwave heating fusion

A platinum group metal, microwave heating technology, applied in the field of precious metal recovery, can solve the problems of high platinum group metal content, high melting temperature, long melting time, etc., to achieve the effect of reducing melting time, low melting point, and reducing reaction activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

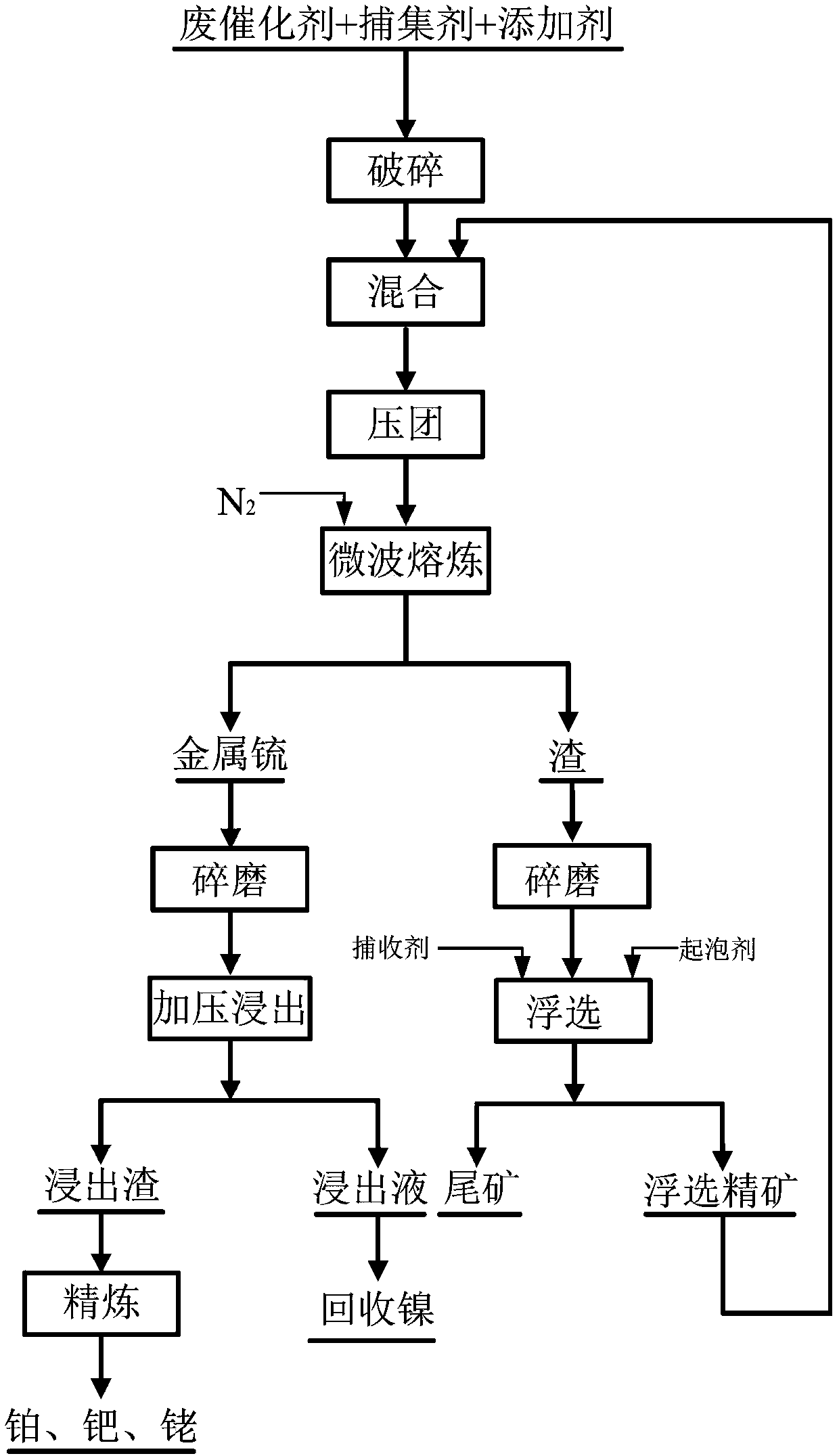

[0055] See attached figure 1 , respectively weighed cordierite ceramic carrier automobile waste catalyst (wherein SiO 2 Around 31.6%, Al 2 o 3 About 39.1%%, about MgO4.6%, Pt 245g / t, Pd 1480g / t, Rh 185.2g / t) 200g, collector 200g (nickel matte, containing Ni 3 S 2 85.78%, NiO 5.89%, Cu 3.22%, Fe 2.5%), sodium carbonate 20g, borax 115g, and crushed until the particle size does not exceed 200 mesh, mixed with water and pressed into a 40mm×40mm×31mm agglomerate, dried and placed In the crucible, the crucible is placed in a microwave vertical melting furnace, the microwave heating frequency is 2450MHz, N2 is introduced as a protective atmosphere during the melting process, the microwave melting temperature is 1100°C, and the melting time is 2 hours. The content of platinum, palladium, and rhodium in the nickel matte obtained after smelting is 0.0486g, 0.2941g, and 0.0361g respectively, and the recovery rates of platinum, palladium, and rhodium calculated from this are 99.18%, ...

Embodiment 2

[0058] See attached figure 1 , respectively weighed cordierite ceramic carrier automobile waste catalyst (wherein SiO 2 Around 31.6%, Al 2 o 3 About 39.1%, MgO about 4.6%, Pt 245g / t, Pd 1480g / t, Rh 185.2g / t) 200g, collector 200g (nickel matte, containing Ni 3 S 2 85.78%, NiO 5.89%, Cu 3.22%, Fe 2.5%), sodium carbonate 0g, borax 115g, and crushed to a particle size of no more than 200 mesh, mixed with water and pressed into a 40mm×40mm×31mm agglomerate, dried and placed In the crucible, the crucible is placed in a microwave vertical melting furnace, the microwave heating frequency is 2450MHz, N2 is introduced as a protective atmosphere during the melting process, the microwave melting temperature is 1100°C, and the melting time is 1.5h. In the nickel matte, and separated from the slag, the contents of platinum, palladium and rhodium in the nickel matte obtained after smelting are 0.0443g, 0.253g, and 0.033g respectively, and the recovery rates of platinum group metals cal...

Embodiment 3

[0060] See attached figure 1 , respectively weighed cordierite ceramic carrier automobile waste catalyst (wherein SiO 2 Around 31.6%, Al 2 o 3 About 39.1%, MgO about 4.6%, Pt 245g / t, Pd 1480g / t, Rh 185.2g / t) 200g, collector 300g (nickel matte, containing Ni 3 S 2 85.78%, NiO 5.89%, Cu3.22%, Fe2.5%), sodium carbonate 10g, borax 80g, and crushed until the particle size does not exceed 200 mesh, mixed with water and pressed into a 40mm×40mm×31mm agglomerate, dried Then put it in the crucible, the crucible is placed in the microwave vertical melting furnace, the microwave heating frequency is 2450MHz, N2 is passed into the protective atmosphere during the melting process, the microwave melting temperature is 1050°C, the melting is 2h, and the platinum group metals are enriched after melting In the nickel matte, and separated from the slag, the contents of platinum, palladium and rhodium in the nickel matte obtained after smelting are 0.0466g, 0.2833g and 0.036g respectively, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com