A kind of preparation method of functional nano-cellulose composite airgel

A technology of nano-cellulose and composite airgel, which is applied in the interdisciplinary fields of polymers, chemical engineering and nano-materials, can solve the problems of unstable cross-linked network structure, low mechanical properties, and unsatisfactory pore structure, and achieve easy control of the process , low production cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

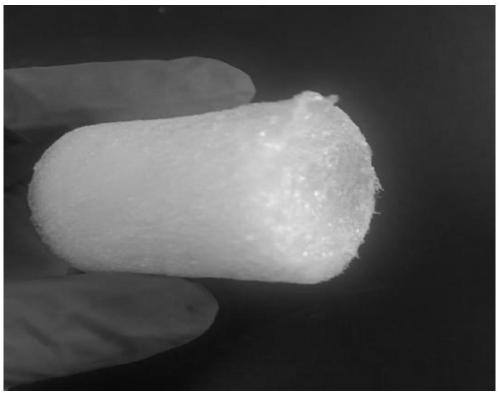

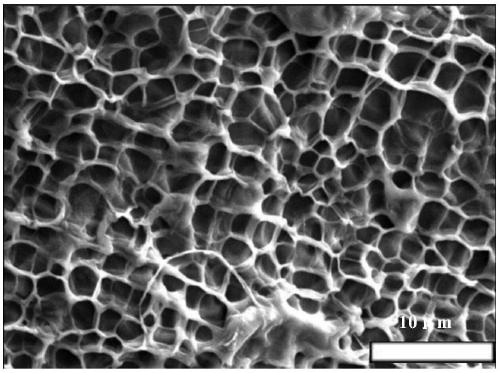

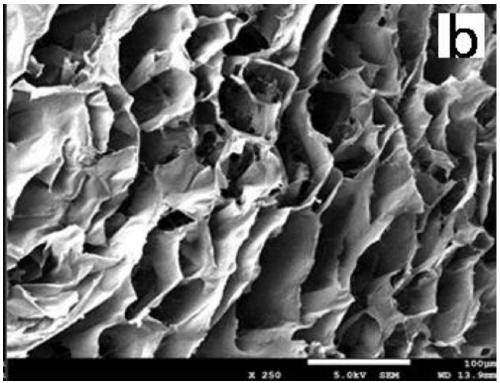

Image

Examples

Embodiment 1

[0029]Disperse 10g (dry weight) coniferous pulp plate in 500mL water, add 0.16g 2,2,6,6-tetramethylpiperidine-nitrogen-oxide and 1.6g sodium bromide at the same time, mix well and add 120mLNaClO Solution, mechanically stirred at room temperature, adjusted and controlled to pH 10.5 by 0.2mol / L NaOH solution, when the pH of the reaction mixture no longer increased, the reaction was stopped, and the resulting nanocellulose was acidified with 0.1mol / L HCl solution Vacuum filter and wash to neutral. The pH of the washed nanocellulose was adjusted to 10, ultrasonically dispersed in deionized water, and the concentration of the solution was adjusted to 1 wt%.

[0030] Put 12g of 1wt% nanocellulose solution and 0.48g of 25wt% polyethyleneimine aqueous solution in a specific mold, add water to dilute to 20mL, stir rapidly for 1h to disperse evenly. Stand at room temperature for 48 hours to obtain nanocellulose-polyethyleneimine hydrogel. Soak the above hydrogel in 0.1wt% glyoxal aque...

Embodiment 2

[0032] Disperse 10g (dry weight) coniferous pulp board in 400mL water, disperse for 10min at 3,000rpm with a deflaker, then process the dispersion at 1,440rpm for 30min to obtain a colloidal nanocellulose solution, adjust its concentration to 2wt% . Take 50g of the above-mentioned 2wt% nanocellulose solution and dilute it to a concentration of 1wt% with a buffer solution with a pH of 7.6, add 2.4g MgCl 2 and 2.8 g of adenosine triphosphate disodium (ATP), while adding hexokinase and controlling the concentration to 35 U / mL, the above mixed solution was reacted at 30° C. for 24 hours. After enzyme inactivation, the phosphorylated nanocellulose was repeatedly washed with deionized water (centrifuged at 6000 rpm for 4 min) until no ATP absorption was detected at a wavelength of 260 nm. The concentration of the washed phosphorylated nanocellulose was adjusted to 1% with deionized water.

[0033] Place 12g of 1wt% phosphated nanocellulose solution, 0.48g of 25wt% polyethyleneimin...

Embodiment 3

[0035] Fully bleached coniferous wood will be pulverized in a pulverizer and crossed a 20-mesh sieve, and the obtained cellulose powder (50.0g) is added to 500mL 64wt%H 2 SO 4 , heated to 45°C under stirring for 45 minutes, then added 10 times deionized water to dilute to terminate the reaction. The mixture was centrifuged at 5000rpm for 10min, and the supernatant was removed. The resulting precipitate was redispersed in deionized water and dialyzed with a regenerated cellulose membrane with a molecular weight cut-off of 12000-14000 for 7 days until the pH value remained unchanged. The dialyzed mixed solution was ultrasonically dispersed in an ice-water bath for 30 minutes, and the obtained sulfonic acid cellulose nanocrystal dispersion was treated with a mixed bed ion exchange resin, adjusted to 1 wt%, and stored in a refrigerator at 5°C.

[0036] Weigh 5g of dried chitosan powder into a four-necked flask, and add 100mL of isopropanol to swell for 30min; then slowly add 10g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com