Manufacturing method of holographic diffractive optical element

A technology for diffractive optical elements and manufacturing methods, which is applied in the field of scopes, can solve problems such as inconsistent performance, difficulty in ensuring quality stability, and high requirements for production conditions, so as to reduce the influence of environmental factors, improve process stability, and improve consistent performance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

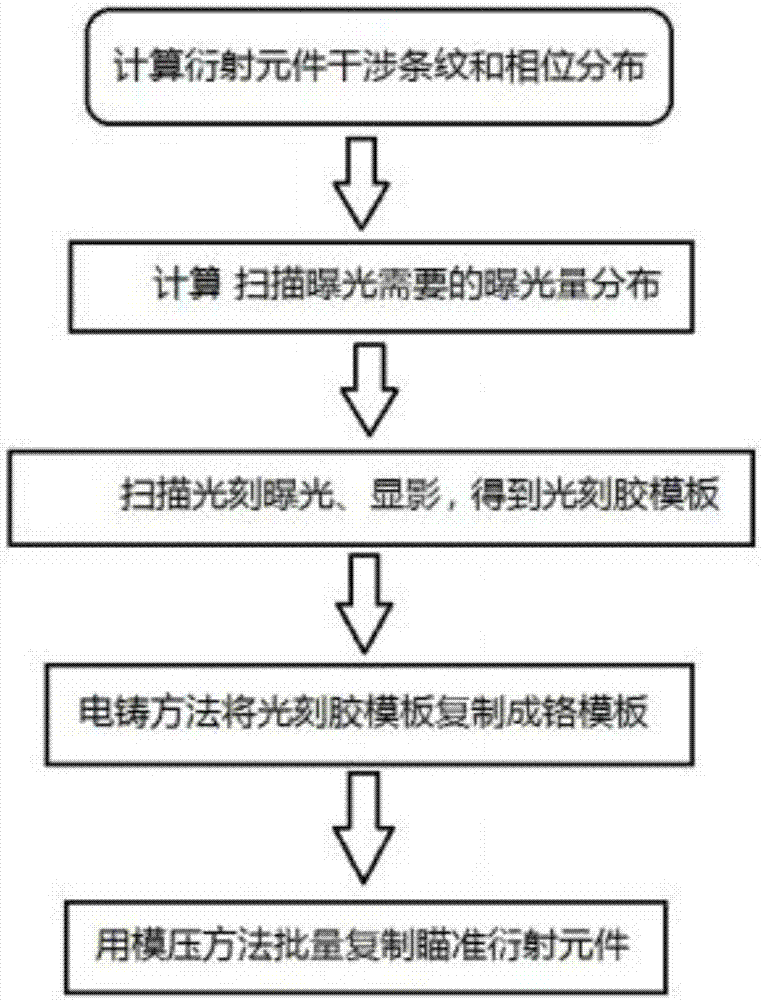

[0026] Such as figure 1 As shown, the present invention provides a method for manufacturing a diffractive optical element of a holographic sight, which includes the following steps:

[0027] S1. Calculate the fringe distribution and phase distribution required on the diffractive optical element; including: determining the working parameters of the diffractive element, and calculating the fringe distribution and the phase distribution according to the working parameters, the principle of optical interference and the principle of Fourier optics Phase distribution; the working parameters include working wavelength, reference incident light angle, and holographic reconstruction light position;

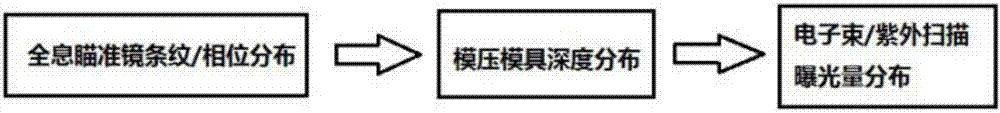

[0028] S2. Converting the fringe distribution and the phase distribution into template depth distribution and exposure distribution;

[0029] S3. According to the depth distribution of the template and the exposure amount distribution, a three-dimensional relief mechanism is fabricated on the pho...

Embodiment 2

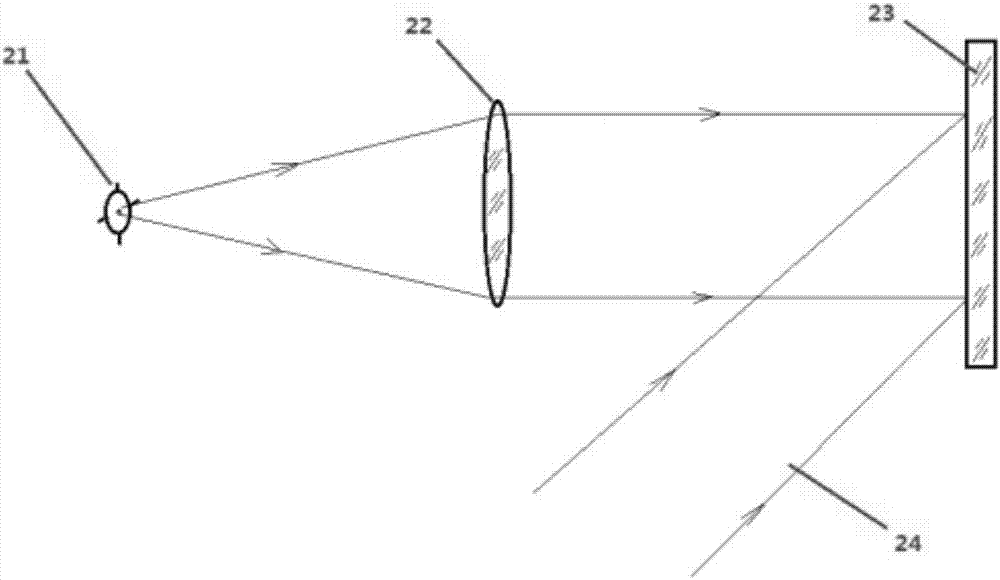

[0035] S1. The distribution and phase of fringes on the holographic aiming lens. according to figure 2 In the ideal light path shown, the aiming cross-hair image 21 is located on the focal plane of the Fourier transform lens 22, and the focal length is f. The light field distribution of the cross-hair image after passing through the lens can be expressed by the following formula:

[0036]

[0037] The angle between the parallel beam 24 and the optical axis of the lens 22 is θ (the θ angle is generally in the range of 45-60 degrees), which can be expressed as:

[0038] R(x,y)=R 0 exp(jkxsinθ)

[0039] The two light fields interfere on the holographic sight 23 to form interference fringe distribution and phase distribution, which can be expressed as:

[0040]

[0041] According to the phase distribution obtained above, combined with the refractive index of the PET film, the depth of the depression required for each point of the PET to achieve the above phase distribution can be calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com