Graphene/ceramic particle synergetic modified epoxy resin paint, preparation method and application thereof

A technology of epoxy resin coatings and ceramic particles, which is applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of difficult large-scale application, high solid content, low efficiency, etc., and achieve low cost and simple preparation process Ease of operation and improvement of erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

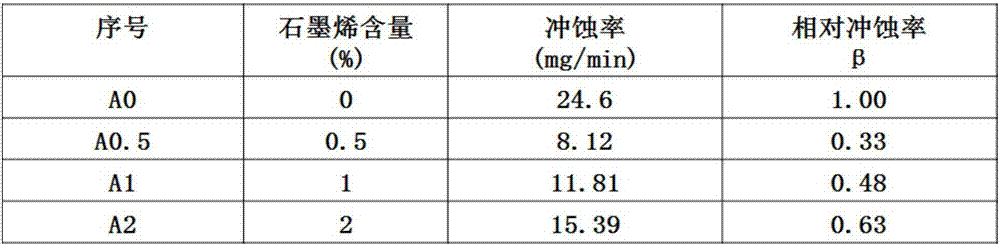

Examples

preparation example Construction

[0034] Another aspect of the embodiments of the present invention provides a method for preparing the aforementioned graphene / ceramic particles synergistically modified epoxy resin coating, which includes:

[0035] (1) Take epoxy resin, silicon carbide particles, aluminum oxide particles, silane coupling agent, graphene and epoxy diluent and mix uniformly to prepare component A;

[0036] (2) B component is provided, and B component is uniformly mixed with described A component, makes described graphene / ceramic particles synergistically modified epoxy resin coating.

[0037] In some specific embodiments, the preparation method may include:

[0038] (1) Weigh a certain proportion of epoxy resin, silicon carbide particles, aluminum oxide particles, silane coupling agent, graphene and epoxy diluent and mix uniformly to prepare component A;

[0039] (2) Add an epoxy curing agent to the A component in a certain proportion, stir and mix evenly, and prepare a graphene / ceramic particl...

Embodiment 1

[0062] Embodiment 1 This embodiment provides a kind of graphene / ceramic particles synergistically modified epoxy resin coating (referred to as epoxy resin coating), and its preparation method comprises:

[0063] Weigh 50% bisphenol A epoxy resin and 50% bisphenol F epoxy resin respectively by mass percentage (if not specified below, then all refer to the mass percentage content of each component in epoxy resin), mix to obtain ring oxygen resin;

[0064] According to mass percentage (if not specified below, it refers to the mass percentage content of each component in component A), respectively take 32% of the epoxy resin, 35% of silicon carbide particles (with a particle size of about 325 mesh), and three Aluminum oxide particles (500 mesh) 10%, silane coupling agent (KH-560) 2.5%, reduced graphene 0.5% and epoxy diluent 20%, disperse and mix uniformly in a high-speed dispersion kettle to prepare component A ;

[0065] Take modified amine T31 as curing agent B component;

...

Embodiment 2

[0067] Embodiment 2 This embodiment provides a kind of graphene / ceramic particles synergistically modified epoxy resin coating, and its preparation method comprises:

[0068] By mass percentage, weigh 60% bisphenol A epoxy resin and 40% bisphenol F epoxy resin respectively, mix to obtain epoxy resin, by mass percentage, get respectively this epoxy resin 20%, silicon carbide particles (800 mesh ) 40%, aluminum oxide particles (325 mesh) 15%, silane coupling agent (KH-550) 4%, reduced graphene 1% and epoxy diluent 20%, after uniform dispersion and mixing in the high-speed dispersion kettle Prepare component A; the mixture of modified amine T31 and diethylenetriamine is component B of the curing agent, and the mass ratio of the two is modified amine T31:diethylenetriamine=2:1; 70% of component A and 30% of component B are dispersed and mixed in a dispersing tank, and stirred evenly to prepare a graphene / ceramic particle synergistically modified epoxy resin coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com