Composite ceramic powder and ceramic forming method

A technology of composite ceramics and ceramic powder, which is applied in the field of additive manufacturing, can solve problems such as increased layer-to-layer stacking direction errors, difficulty in forming parts, and increased number of printing layers, achieving increased transmission depth, uniform transmission, refraction and The effect of increased transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

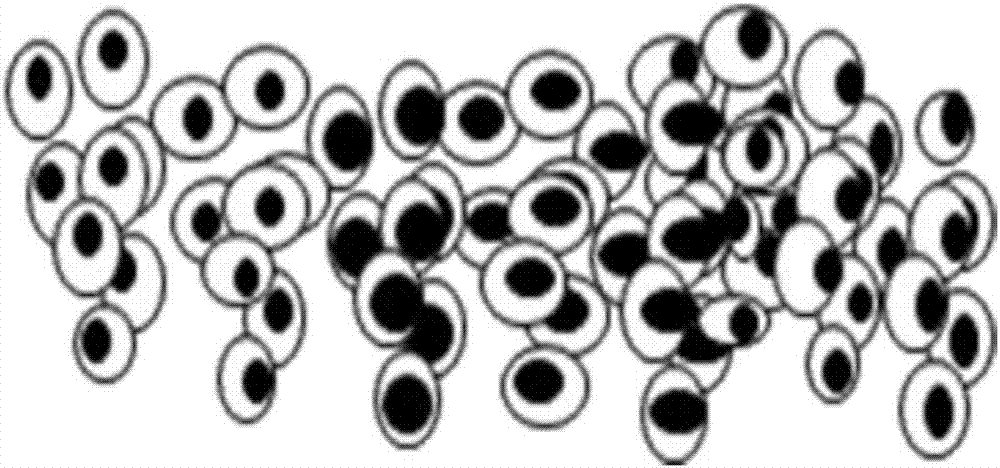

[0062] Example 1 Preparation of composite ceramic powder by precipitation method

[0063] SiC powder, butyl titanate with a mass fraction of 50%-80% of SiC, and absolute ethanol with a mass fraction of 1-4 times SiC are added to the container, and are thoroughly mixed with a ball mill. Add deionized water under vigorous stirring to control the molar ratio of butyl titanate to deionized water n(Ti):n(H 2 O) is 1:150. A precipitate formed at room temperature, filtered and washed. TiO is formed after drying at 80°C 2 Coated SiC particles.

Embodiment 2

[0064] Example 2 Preparation of composite ceramic powder by hydrolysis method

[0065] In the first step, methoxyethanol and tetraisopropyl titanate are added to the anhydrous isopropanol solution, and the solution is simmered at 75°C-85°C for 1h-3h and then loaded into a volumetric flask for use. The molar ratio of methoxyethanol to tetraisopropyl titanate is 4:1. In the second step, add 3g-5g of SiC powder to the beaker, add 100ml-200ml of anhydrous isopropanol, add 20ml-50ml of deionized water, dropwise add the solution prepared in the first step, 75℃-85 ℃ migrating 0.5h-3h to form TiO 2 Coated SiC particles.

Embodiment 3

[0066] Example 3 Preparation of composite ceramic powder by heterogeneous nucleation method

[0067] Fully disperse the SiC powder in a solution containing a dispersant, add Al(NO) 3 ) 3 , AlCl 3 , Al 2 (SO 4 ) 3 The solution is vigorously stirred, and at the same time, ammonia water is added to control the pH value, so that SiC becomes the core of the sol generation and generates Al(OH) 3 The coated SiC is precipitated, and then filtered and dried to obtain Al 2 O 3 Coated SiC particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com