A kind of protective coating for clear water facing concrete and preparation method thereof

A technology of facing concrete and protective coating, which is applied in the field of building materials, can solve the problems of inapplicable urban existing building structures in the later maintenance, and the appearance of concrete structures is greatly affected, so as to solve surface pollution, low cost, and increase hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

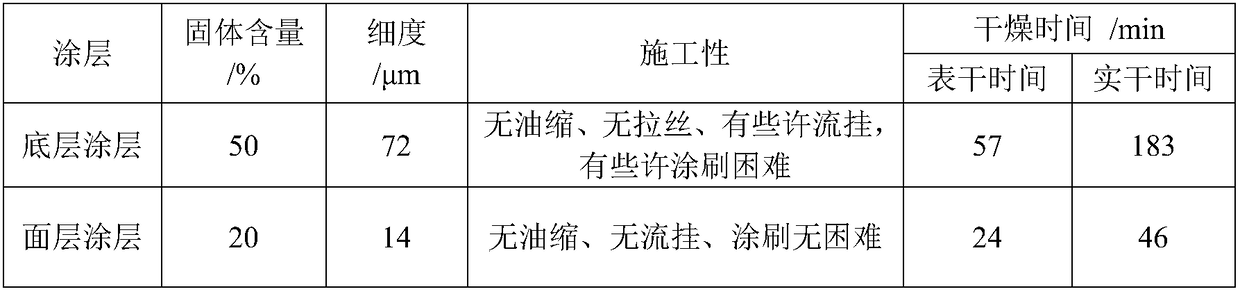

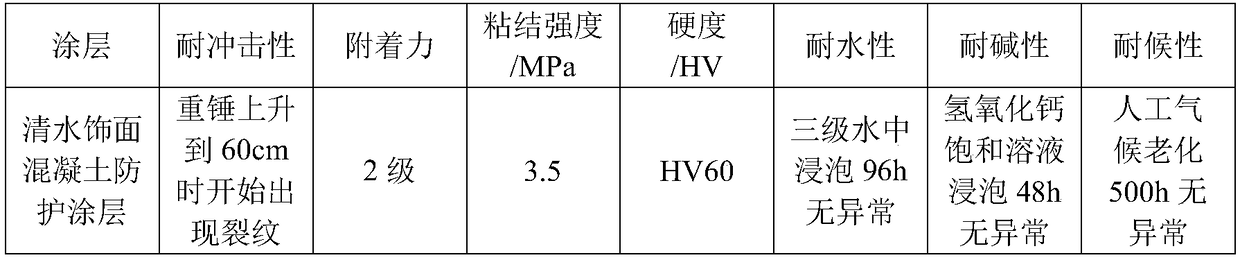

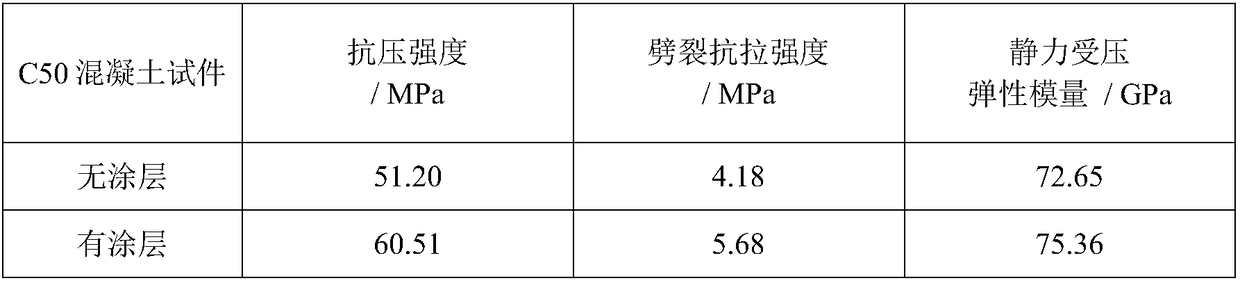

Embodiment 1

[0025] A clear-faced concrete protective coating is prepared by the following method:

[0026] 1) Primer coating: the mass ratio of cement, silica fume, sodium dodecylsulfonate, styrene-acrylate dispersible latex powder is 60:30:1:9, water-binder ratio = 1.0; surface coating Layer: the mass ratio of silane emulsion, ultrafine aluminum silicate and lithium silicate is 90:5:5;

[0027] 2) Pour the weighed cement, silica fume, sodium lauryl sulfonate and dispersible latex powder into the concrete mixer and dry mix for 2 to 3 minutes to obtain the dry powder of the bottom coating of the clear water facing concrete protective coating;

[0028] 3) Pour the weighed silane emulsion, ultra-fine aluminum silicate and lithium silicate into the mixer and stir for 5-10 minutes to obtain the mixed emulsion of clear water facing concrete protective coating surface layer coating;

[0029] 4) The concrete base surface needs to be cleaned and moistened before the primer coating is applied to r...

Embodiment 2

[0045] A clear-faced concrete protective coating is prepared by the following method:

[0046] 1) Primer coating: the mass ratio of cement, silica fume, sodium dodecylsulfonate, styrene-acrylate dispersible latex powder is 65:25:1:9, water-binder ratio = 0.95; surface coating Layer: the mass ratio of silane emulsion, ultrafine aluminum silicate and lithium silicate is 90:5:5;

[0047] 2) Pour the weighed cement, silica fume, sodium lauryl sulfonate and dispersible latex powder into the concrete mixer and dry mix for 2 to 3 minutes to obtain the dry powder of the bottom coating of the clear water facing concrete protective coating;

[0048] 3) Pour the weighed silane emulsion, ultra-fine aluminum silicate and lithium silicate into the mixer and stir for 5-10 minutes to obtain the mixed emulsion of clear water facing concrete protective coating surface layer coating;

[0049] 4) The concrete base surface needs to be cleaned and moistened before the primer coating is applied to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com