Porous silicon nano-material and preparation method and use thereof

A nanomaterial and porous silicon technology, applied in the field of preparation of porous silicon nanomaterials, can solve the problems of harsh synthesis conditions, low yield, single Si quantum dots, etc., and achieve the effects of simple operation, high yield and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

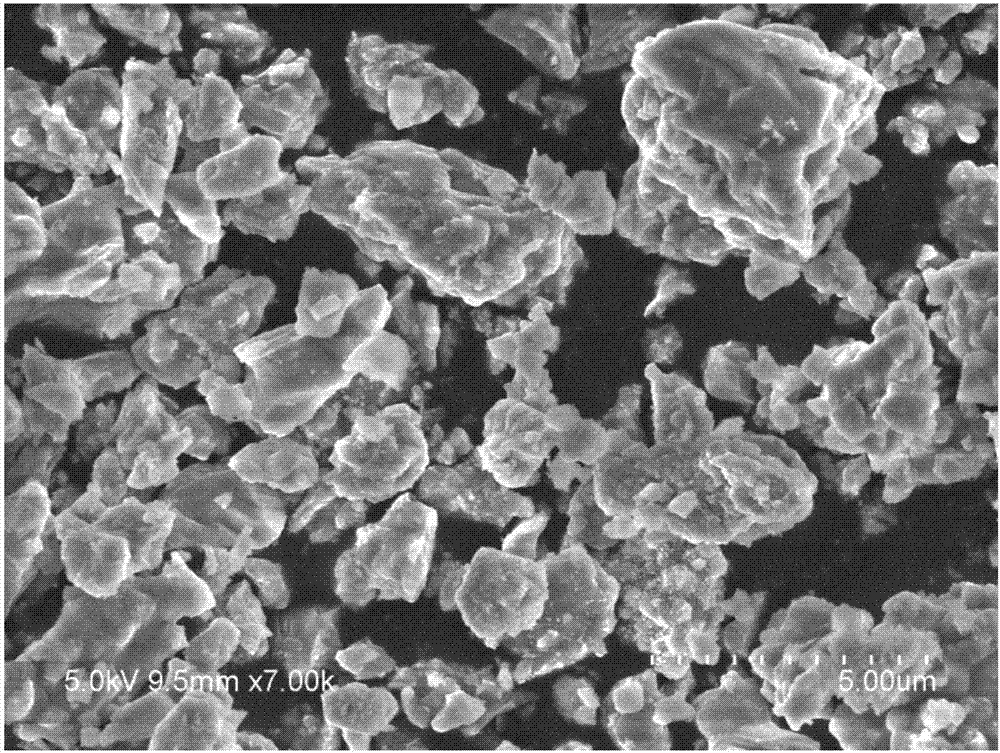

[0040] Step 1: Mix 1 mL of tri-n-propylamine and 1.1 mL of HSiCl 3 Add to 40 mL anhydrous CH 2 Cl 2 , stirred overnight at room temperature. Add 1 g Mg 2 Si (Mg 2 The scanning electron microscope pictures of Si are shown in figure 1 , lumpy solid, no particular shape), stirred and reacted at room temperature for 10 hours. Centrifuge, wash with chloroform 3-4 times, and dry in vacuo to obtain a brown solid.

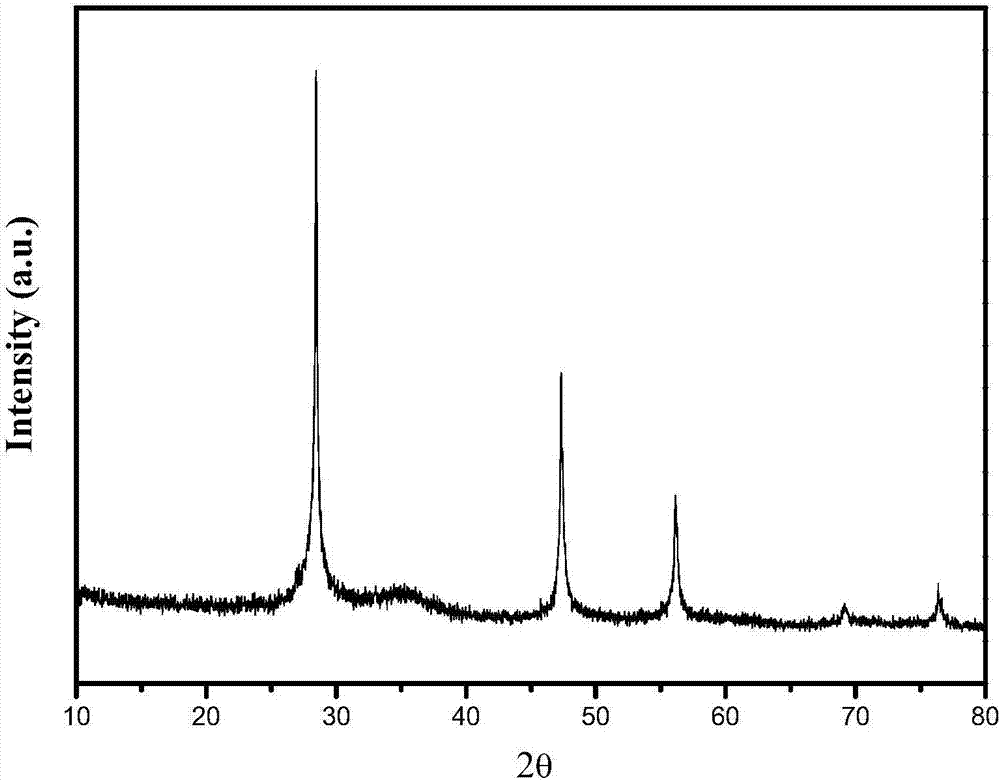

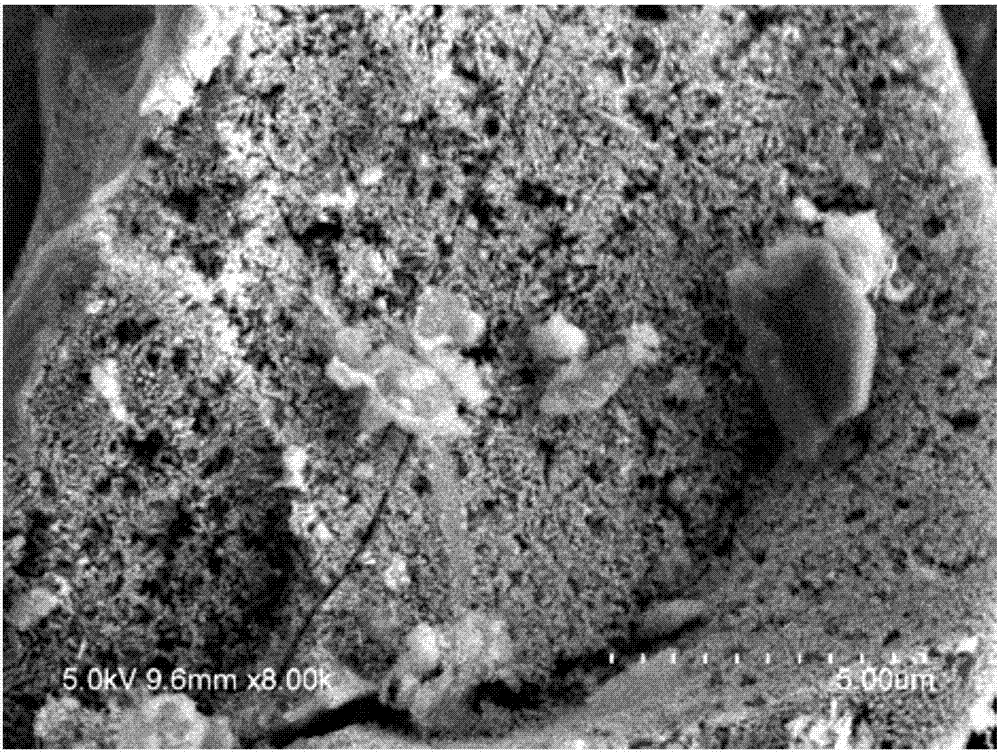

[0041] Step 2: Put the obtained brown solid in a tube furnace with high-purity Ar gas at 15°C min -1 Heat at a heating rate of 700°C and hold for 30 minutes. After natural cooling, the obtained solid was washed with 1 M HCl, and then washed several times with distilled water, and dried in vacuum to obtain about 0.5 g (yield 74%) of yellow-brown porous silicon nanomaterials. figure 2 It is an X-ray powder diffraction pattern of the porous silicon nanomaterial, and it can be seen from the figure that the silicon material obtained by high temperature treatment is cr...

Embodiment 2

[0046] 1.1 mL HSiCl 3 Add to 40 mL anhydrous CH 2 Cl 2 , stirred overnight at room temperature. Add 1 g Mg 2 Si, the reaction was stirred at room temperature for 48 hours. centrifuged, washed 3-4 times with chloroform, and dried in vacuo, the gray solid obtained was unreacted Mg 2 Si and a small amount (about 20 mg, yield less than 10%) of Si nanoparticles. Compared with Example 1, in the absence of activator, porous silicon nanomaterials with mesoporous channels cannot be obtained.

Embodiment 3

[0048] Mix 1 mL of tri-n-butylamine and 1.1 mL of HSiCl 3 Add to 40 mL anhydrous CH 2 Cl 2 , stirred overnight at room temperature. Add 1 gMg 2 Si, the reaction was stirred at room temperature for 12 hours. Centrifuge, wash with chloroform 3-4 times, and dry in vacuo to obtain a brown solid.

[0049] The obtained brown solid was placed in a tube furnace with high-purity Ar gas at 15 °C min -1 Heat at a heating rate of 700°C and hold for 30 minutes. After natural cooling, the obtained solid was washed with 1 M HCl, and then washed several times with distilled water, and dried in vacuum to obtain about 0.5 g of yellow-brown crystalline porous silicon nanomaterials. The X-ray powder diffraction results of the porous silicon nanomaterial and figure 2 Basically the same. The nitrogen adsorption test results show that the specific surface area of the material is 185 m 2 g -1 , showing distinct mesoporous channels (pore diameters around 3.5 nm and 25 nm). Referring to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com