A kind of nano-silicon material and its application

A nano-silicon and nano-technology, which is applied in the application of negative electrode materials for lithium ion batteries, in the field of nano-silicon materials, can solve the problems of difficulty in synthesis, difficulty in meeting large-scale production, increase in synthesis cost, etc., and achieves low cost, easy amplification and synthesis, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

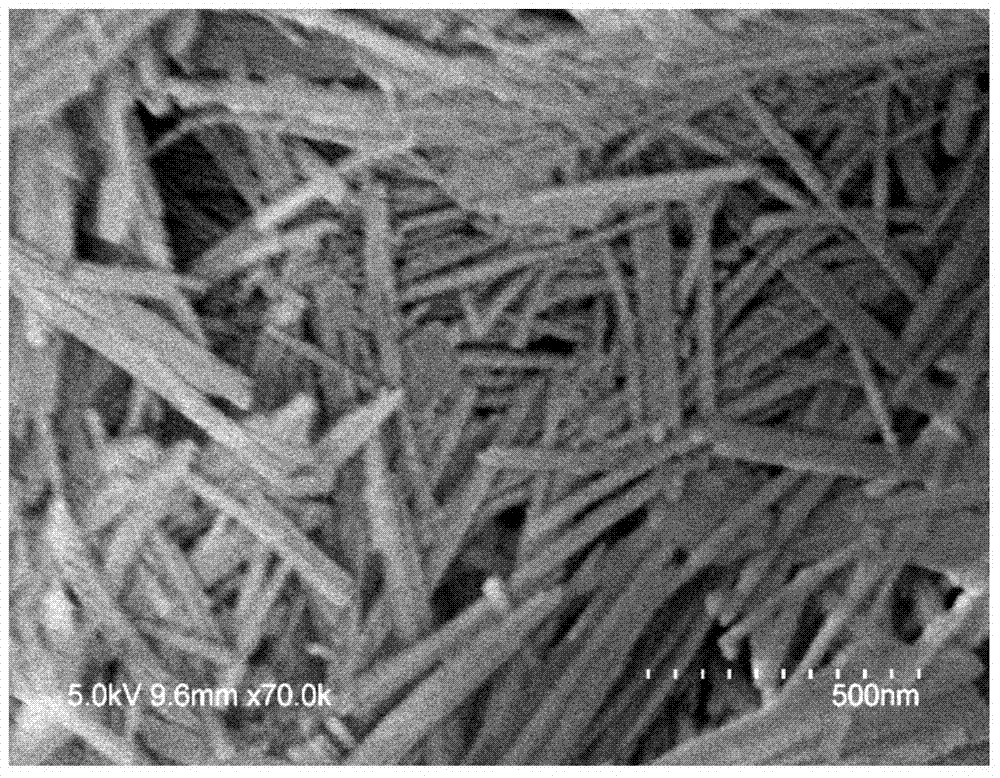

[0044]Step 1: Pass the untreated attapulgite through a 200-mesh molecular sieve, add 10 g to 300 mL of 2M HCl solution, and react at 70° C. for 30 h. Filtrate, wash with water until neutral, dry in an oven at 80°C, and heat-treat in a muffle furnace at 600°C for 4 hours to obtain nano-SiO with a rod-like structure 2 . Its scanning electron microscope pictures are as figure 1 As shown, the length is 300-800 nm and the width is 20-40 nm.

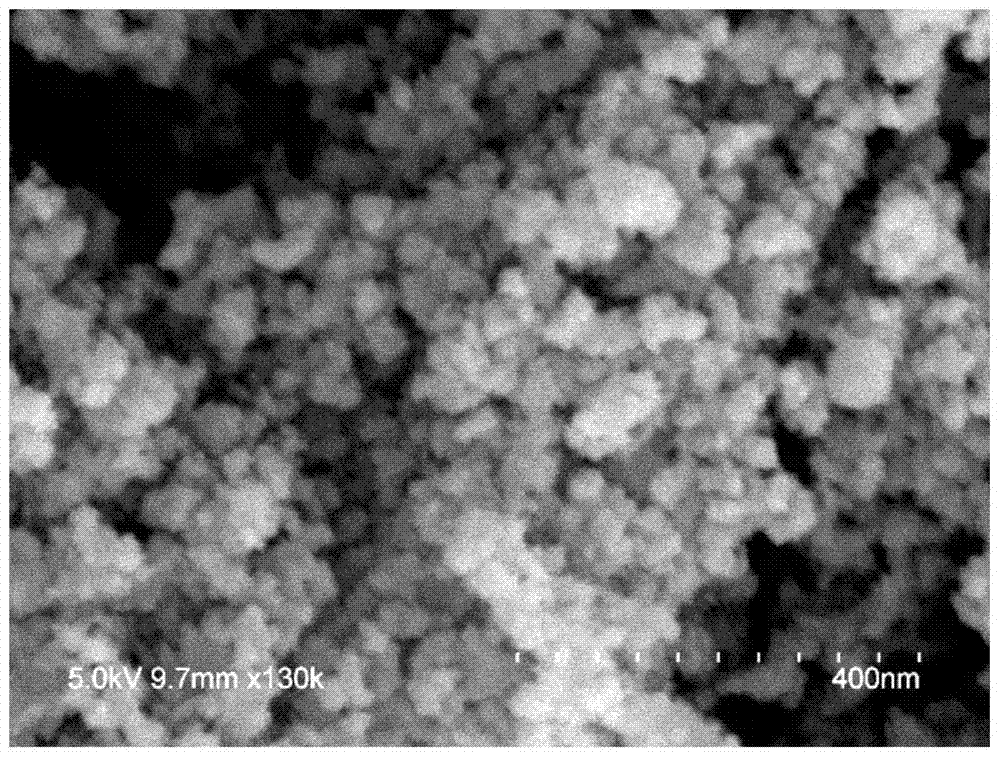

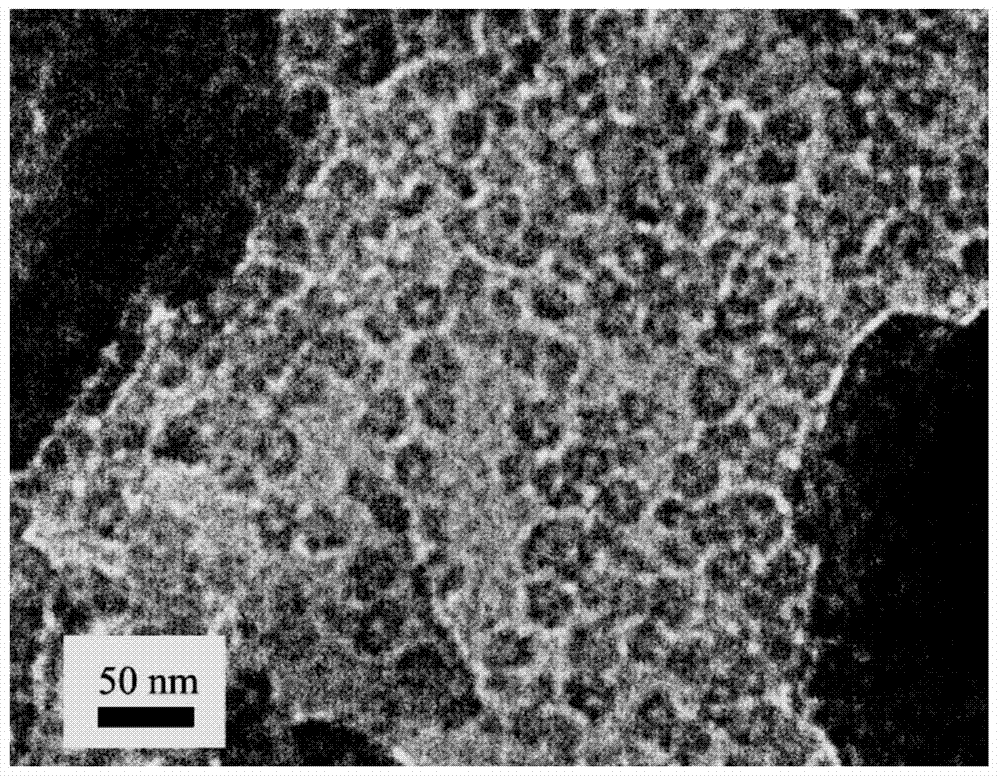

[0045] The second step: the Mg and SiO 2 The powder is ground evenly with a molar ratio of 2:1 (2g SiO 2 ), placed in a porcelain boat, reacted in a tube furnace at 680°C for 4h under an Ar atmosphere, and the product was stirred and reacted at room temperature for 5h and 10min respectively in 1M HCl and 6% HF to obtain a uniform particle size distribution less than 100nm Elemental silicon material (0.8g), its scanning electron microscope photo is as follows figure 2 shown. From its transmission electron microscope pictures (such as i...

Embodiment 2

[0050] The first step, the third step and the fourth step are shown in Example 1, and the second step is the second step Mg powder and SiO in Example 1 2 The molar ratio of 3:1 (2g SiO 2 ), where the magnesium powder is placed on the lower layer of the porcelain boat, SiO 2 Uniformly coated on the upper porous stainless steel mesh, reacted at 850°C for 5h. The charge-discharge performance and discharge capacity of the battery obtained are the same as those in Example 1.

Embodiment 3

[0052] See Example 1 for the first, second and fourth steps. In the third step, the source of C to coat Si comes from glucose, and the obtained elemental silicon material is ultrasonically dispersed in an ethanol solution dissolved with a certain amount of glucose, at 200°C Hydrothermal treatment for 5h. The filtered, washed and dried samples were heat-treated in a tube furnace at 700 °C for 3 h under an Ar atmosphere. The charge-discharge performance and discharge capacity of the battery obtained are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com