Antifreeze asphalt mixture and preparation method thereof

A technology for asphalt mixture and anti-condensation ice, applied in the field of anti-condensation ice asphalt mixture and its preparation, can solve the problems of reduced road friction, traffic accidents, thin ice formation on the road surface, etc., so as to reduce the freezing point of the road surface and prevent the road surface from freezing. , Enhance the effect of road friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

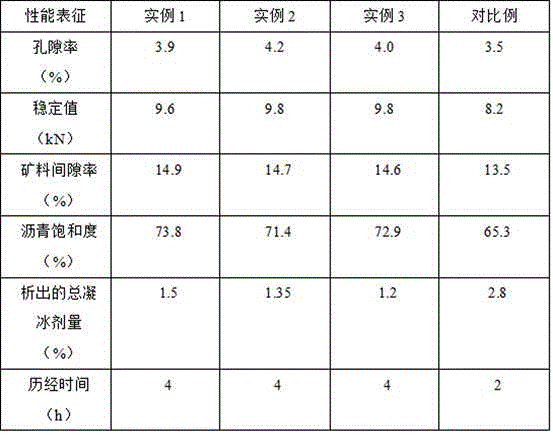

Examples

example 1

[0025] Take 100g of calcium carbide slag and 20g of magnesium oxide, add them into 300mL of deionized water, stir at 300r / min at 50°C for 20min, then add 120g of glacial acetic acid, continue stirring for 1h, cool to room temperature and filter to obtain the filtrate, take 30g of diatomaceous earth Pulverize in a pulverizer, pass through a 40-mesh sieve, add the sieved diatomite powder to the filtrate, stir at 200r / min for 20min, then add 10g of methyltriethoxysilane, and disperse with 300W ultrasonic wave for 20min before loading Put it into a rotary evaporator, evaporate to dryness at 120 ° C, then transfer it to a mortar for grinding, and pass through a 80-mesh sieve to obtain an anti-icing agent. Take limestone and put it into a jaw crusher for primary crushing, and then transfer it to a disc type Secondary crushing in the crusher, and transferred to the vibrating screen machine, the limestone crushed stones with different particle sizes were screened out, and the crushed s...

example 2

[0027] Take 150g of carbide slag and 30g of magnesium oxide, add it to 400mL of deionized water, stir at 55°C at 350r / min for 25min, then add 180g of glacial acetic acid, continue stirring for 1h, cool to room temperature and filter to obtain the filtrate, take 40g of diatomaceous earth Pulverize in a pulverizer, pass through a 40-mesh sieve, add the sieved diatomite powder to the filtrate, stir at 250r / min for 25min, then add 15g of methyltriethoxysilane, and disperse with 300W ultrasonic wave for 25min before loading Put it into a rotary evaporator, evaporate to dryness at 125°C, then transfer it to a mortar for grinding, and pass through a 80-mesh sieve to obtain an anti-icing agent. Take limestone and put it into a jaw crusher for primary crushing, and then transfer it to a disc type Secondary crushing in the crusher, and transferred to the vibrating screen machine, the limestone crushed stones with different particle sizes were screened out, and the crushed stones were loa...

example 3

[0029] Take 200g of calcium carbide slag, 40g of magnesium oxide, add 500mL of deionized water, stir at 60°C at 400r / min for 30min, then add 240g of glacial acetic acid, continue stirring for 2h, cool to room temperature and filter to obtain the filtrate, take 50g of diatomaceous earth Pulverize in a pulverizer, pass through a 40-mesh sieve, add the sieved diatomite powder into the filtrate, stir at 300r / min for 30min, then add 20g of methyltriethoxysilane, and disperse with 300W ultrasonic wave for 30min before loading Put it into a rotary evaporator, evaporate to dryness at 130°C, then transfer it to a mortar for grinding, and pass through a 80-mesh sieve to obtain an anti-icing agent. Take limestone and put it into a jaw crusher for primary crushing, and then transfer it to a disc type Secondary crushing in the crusher, and transfer to the vibrating screen machine, respectively screen out limestone gravels with different particle sizes, put the crushed stones into the mixer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com