High-temperature resistant low-dilatation coefficient heat conduction potting adhesive as well as preparation method and application thereof

A low expansion coefficient, heat conduction potting technology, applied in the field of potting glue, can solve the problems of high temperature resistance and small volume expansion coefficient of PTC potting glue, achieve good adhesion, increase dosage, and enhance thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

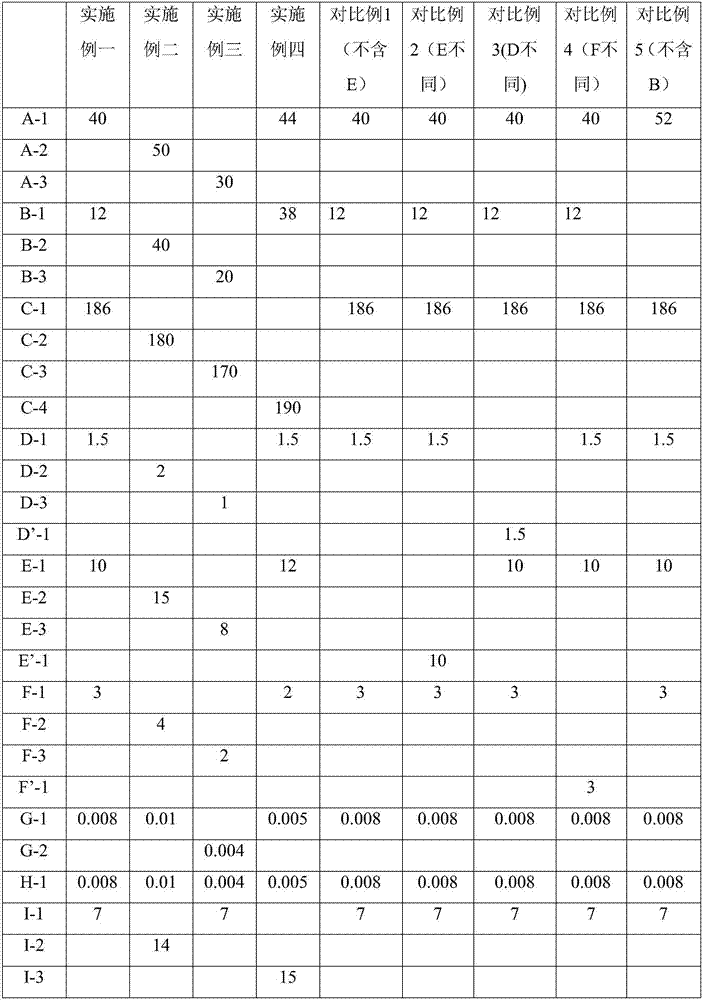

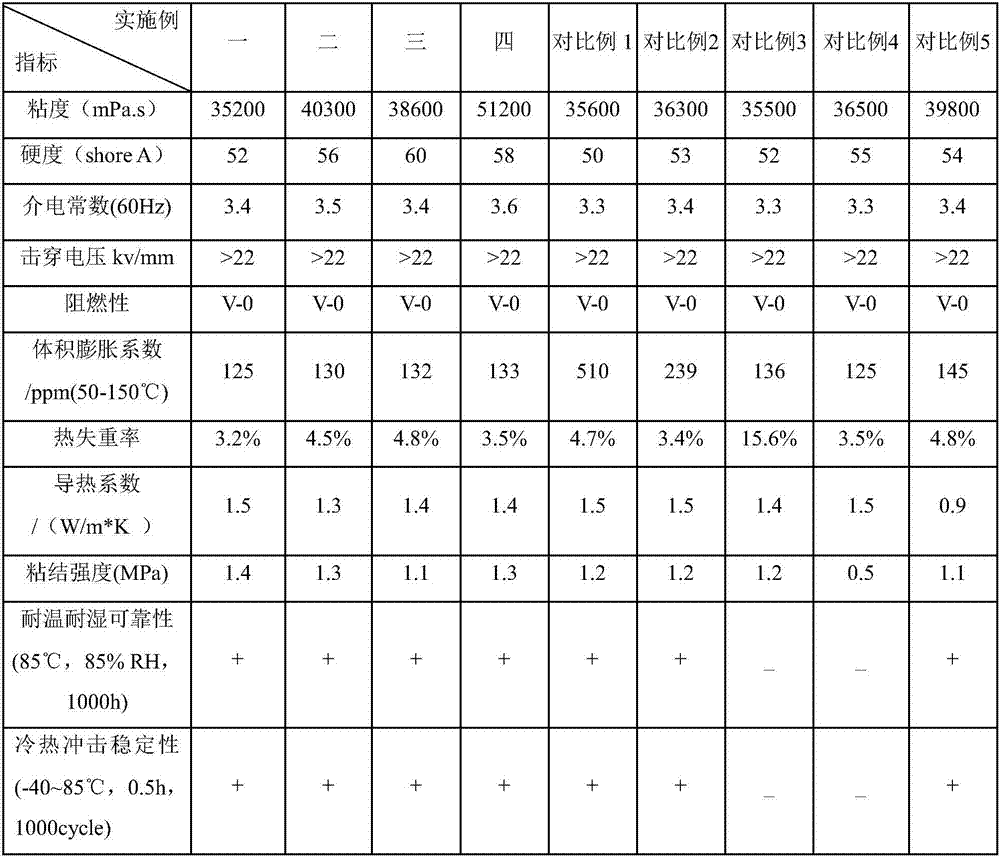

[0031] Example Heat-conducting potting compound with high temperature resistance and low expansion coefficient

[0032] A-1 is a terminal group vinyl silicone oil with a viscosity of 300mPa.s and a vinyl content of 0.8%;

[0033] A-2 is a terminal vinyl silicone oil with a viscosity of 400Mpa.s and a vinyl content of 0.5%;

[0034] A-3 is a terminal vinyl silicone oil with a viscosity of 300MPa.s and a vinyl content of 0.8%;

[0035] B-1 is a hydroxyl vinyl oligomer with a viscosity of 30MPa.s and a vinyl content of 2.5%;

[0036] B-2 is a hydroxyvinyl oligomer with a viscosity of 40MPa.s and a vinyl content of 2%;

[0037] B-3 is a hydroxyvinyl oligomer with a viscosity of 25MPa.s and a vinyl content of 3%;

[0038] C-1 is aluminum powder and boron nitride with coating treatment on the surface, in which the average particle size of aluminum powder is 3 μm, boron nitride is a flake substance, and the content of boron nitride is 9%;

[0039] C-2 is spherical alumina, the av...

Embodiment 1

[0062] The preparation method of embodiment one comprises the steps:

[0063] S1 prepares A component and B component respectively; 1 and 10 parts of E-1 were stirred at a speed of 400r / min for 50min under the environment of vacuum degree of -0.06MPa and temperature of 28°C to obtain component A; the preparation method of component B was as follows: weigh 20 parts A-1, 6 parts of B-1, 7 parts of I-1, 1 part of D-1, 93 parts of C-1, 3 parts of F-1 and 0.008 parts of H-1, at a vacuum of -0.06MPa and a temperature of Stir at a speed of 400r / min for 50min at 28°C to obtain component B;

[0064] S2 defoaming and sub-packaging: put the A component and B component prepared in S1 in a high-speed defoaming machine, defoam at a speed of 3000r / min, pack, and obtain a high-temperature-resistant heat-conducting potting compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com