Metal cup for conical or arc-shaped diamond composite sheet and preparation method thereof

A diamond composite sheet and metal cup technology, applied in the field of superhard material products, can solve the problems of easy adsorption of gas or impurities, low wear resistance, large specific surface area of metal powder, etc., to improve product yield, improve stress distribution, Effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

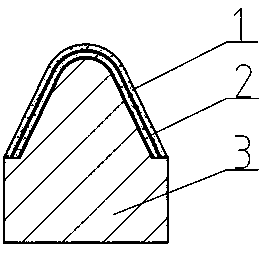

Image

Examples

Embodiment 1

[0025] A metal cup for a conical or arc-shaped diamond composite sheet, expressed in weight percentage, composed of the following alloy components: Ni: 15-20%, Cu: 5-10%, Al: 1-5%, Ti: 0.2 -1%, Si: 1-3%, W: 0.5-1.5%, and the balance is Co.

[0026] Expressed in weight percent, it consists of the following alloy components: Ni: 15%, Cu: 5%, Al: 1%, Ti: 1%, Si: 3%, W: 1.5%, and the balance is Co.

[0027] Expressed in weight percent, it consists of the following alloy components: Ni: 17.5%, Cu: 7.5%, Al: 3%, Ti: 0.6%, Si: 2%, W: 1%, and the balance is Co.

[0028] Expressed in weight percent, it consists of the following alloy components: Ni: 20%, Cu: 10%, Al: 5%, Ti: 1%, Si: 3%, W: 0.5%, and the balance is Co.

[0029] The alloy components are all powders with a mesh size of 600 or less.

[0030] Such as the preparation method of the metal cup for the above-mentioned conical or arc-shaped diamond composite sheet, the specific steps are as follows:

[0031] a. Weigh each allo...

Embodiment 2

[0040] A metal cup for conical or arc-shaped diamond composite sheet, expressed in weight percentage, composed of the following alloy components: Ni: 15%, Cu: 5%, Al: 1%, Ti: 0.2%, Si: 1% , W: 0.5%, the balance is Co.

[0041] The alloy components are all powders with a mesh size of 600 or less.

[0042] Such as the preparation method of the metal cup for the above-mentioned conical or arc-shaped diamond composite sheet, the specific steps are as follows:

[0043] a. Weigh each alloy component according to the weight percentage described in claim 1, place it in an intermediate frequency furnace for melting, the melting temperature is 1400°C, keep it for 15min after melting, and then cast it into an alloy ingot;

[0044] b, the alloy ingot obtained in step a is sent into a vacuum degree of 10 -3 Refining is carried out at 1450°C in a MPa high-vacuum melting furnace, during which argon gas is introduced for protection, and it is kept for 20 minutes after melting, and then cast...

Embodiment 3

[0052] A metal cup for conical or arc-shaped diamond composite sheet, expressed in weight percentage, composed of the following alloy components: Ni: 15.5%, Cu: 5.5%, Al: 1.4%, Ti: 0.25%, Si: 1.2% , W: 0.6%, the balance is Co.

[0053]The alloy components are all powders with a mesh size of 600 or less.

[0054] Such as the preparation method of the metal cup for the above-mentioned conical or arc-shaped diamond composite sheet, the specific steps are as follows:

[0055] a. Weigh each alloy component according to the weight percentage described in claim 1, place it in an intermediate frequency furnace for melting, the melting temperature is 1410°C, keep it for 16min after melting, and then cast it into an alloy ingot;

[0056] b. Sending the alloy ingot obtained in step a into a vacuum degree of 2×10 -3 Refining is carried out at 1460°C in a high vacuum melting furnace of MPa, during which argon gas is introduced for protection, and it is kept for 21 minutes after melting, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com