Acroptilon repens and Artemisia integrifolia wine and brewing process of same

The technology of Shuanghao wine and process is applied in the field of Shuanghao wine and its brewing technology, which can solve the problems of low utilization rate of raw materials, destruction of nutrients in processing raw materials, etc., and achieves stable color, improved quality and taste, and shortened aging time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

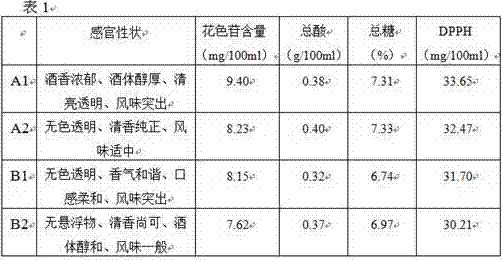

Examples

Embodiment 1

[0034] a. Wash the fresh Artemisia annua and Artemisia artemisiae and chop them into granules, mix Artemisia annua granules with Artemisia artemisiae granules (weight ratio: 100:85) to prepare a mixture, and put the mixture under the condition of 131°C Steam fixation for 18 seconds, after finishing, put the mixed material into 69% vol white wine with an alcohol content of 2.4 times its weight and soak for 28 days, take out after soaking to obtain soaked wine, raw material granules, and ultrafinely pulverize the raw material granules, Prepare raw material powder;

[0035] b. Wash and cut the Jerusalem artichoke into pieces, then cook it to obtain the Jerusalem artichoke material, and add raw material powder (weight ratio: 100:66) to the Jerusalem artichoke material to obtain a mixture;

[0036] c. Add wheat koji, Qumai, pea powder, bran, oat powder, hawthorn powder, wine mother, drinking water to the mixture (weight ratio is 100:44:38:30:28:23:18:15:280) , mixed evenly to obta...

Embodiment 2

[0042] a. Clean fresh Artemisia oleifera, Artemisia annua, Trichosanthes leaves, Dendrobium dendrobium, Wintersweet root, and Millet Spatholobus, and then chop them into pieces. Root grains and Caulis Spatholobus grains (weight ratio: 100:85:56:35:20:15) are mixed evenly to prepare a mixture, and the mixture is steamed at 127°C for 30 seconds, and then put the mixture into its weight 2.8 times the alcohol content is 67%vol white wine soaked for 35 days, after soaking, take out the soaked wine and raw material granules, and carry out ultrafine grinding of the raw material granules to obtain raw material powder;

[0043] b. Wash and cut the Jerusalem artichoke into pieces and steam to obtain the Jerusalem artichoke material, and add raw material powder, yam powder, pomegranate seed powder, barley powder, and Gorgon seed powder to the Jerusalem artichoke material (the weight ratio is 100:63:45:32:16 :10), to prepare the mixture;

[0044] c. Add wheat koji, black corn flour, oatmea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com