Environment-friendly waterproof ultra-fine fibre glass cotton felt for building heat insulation and preparation method of environment-friendly waterproof ultra-fine fibre glass cotton felt

A technology of ultra-fine glass fiber and glass fiber wool, which is applied in the direction of glass manufacturing equipment, building components, chemical instruments and methods, etc., and can solve the problems of low thermal resistance of glass fiber wool for building insulation, failure of glass wool to absorb moisture, and resistance to heat. Water modification treatment and other issues to achieve the effect of improving the fluxing effect, helping fiber refinement, and reducing the temperature of fiber formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

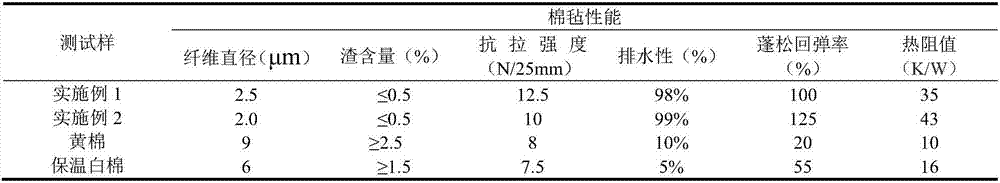

Examples

Embodiment 1

[0026] Preparation of environmentally friendly water-resistant ultra-fine glass fiber felt for building insulation

[0027] (1) Weigh 28 parts of quartz sand, 6.5 parts of albite powder, 4.5 parts of potassium feldspar powder, 10 parts of soda ash, 4.5 parts of calcite, 6.5 parts of dolomite, 9.5 parts of borax, 1.5 parts of zinc oxide and 2 parts of barium carbonate according to the mass ratio and mix them evenly Then put it into the kiln for calcination, and smelt it into a glass liquid with uniform composition, no impurities and transparency, and the temperature of the obtained glass liquid is 1125°C;

[0028] (2) the molten glass obtained in the step (1) flows into a high-speed rotating temperature with a flow rate of 400kg / h through the drain plate to get rid of ultrafine glass fibers in a centrifugal disc of 1025°C;

[0029](3) At a spray pressure of 0.55MPa and a spray flow rate of 265kg / h, the flame cotton mixed with amino silicone oil and Wacker silicone oil is evenly...

Embodiment 2

[0032] Preparation of environmentally friendly water-resistant ultra-fine glass fiber felt for building insulation

[0033] (1) Take 29 parts of quartz sand, 5.5 parts of albite powder, 4 parts of potassium feldspar powder, 9.5 parts of soda ash, 5 parts of calcite, 6 parts of dolomite, 10.5 parts of borax, 2 parts of zinc oxide and 1.5 parts of barium carbonate according to the mass ratio and mix evenly After that, put it into the kiln for calcination, and smelt it into a glass liquid with uniform composition, no impurities and transparency, and the temperature of the obtained glass liquid is 1115°C;

[0034] (2) the molten glass obtained in the step (1) flows into a high-speed rotating temperature with a flow rate of 385kg / h through the drain plate to get rid of ultrafine glass fibers in a centrifugal disc of 1020°C;

[0035] (3) Press the injection pressure of 0.6MPa, the injection flow rate of 295kg / h will be mixed with the flame cotton of hydroxyl silicone oil and amino s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com