Premna microphylla bean curds as well as processing method and application thereof

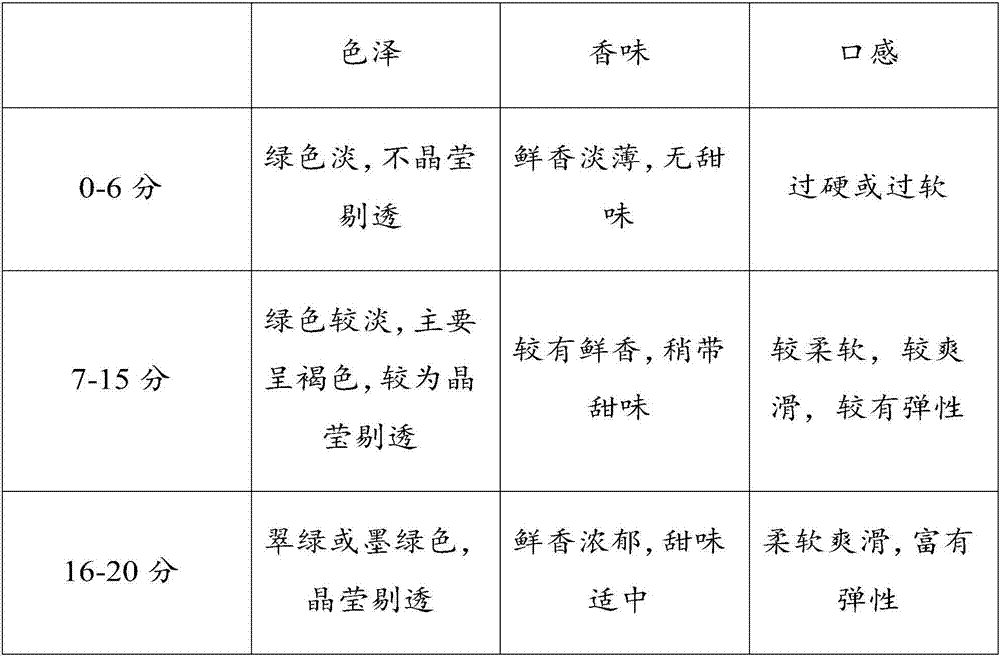

The technology of Guanyin tofu and its processing method is applied in the field of food processing, which can solve the problems that the color and fragrance of Guanyin tofu cannot reach a better balance state, and the raw materials for making Guanyin tofu are single, and achieve the effect of emerald green color, low cost, and strong umami taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The fresh leaves of Doufuchai picked in June with an unearthed height of 15 cm were mixed with water at a weight ratio of 1:5, beaten, and filtered to obtain a filtrate.

[0045] The plant material is dried to a moisture content of 30%, and then burned to obtain plant ash. The above plant ash and water were mixed at a weight ratio of 1:45, fermented at 10°C for 5 days, and the precipitate was removed to obtain plant ash water.

[0046] The auxiliary material is obtained by mixing fungus, kelp, lotus root and fish skin in a weight ratio of 0.7:6:2:6. Chop the ingredients and grind them into a puree.

[0047] Mix the above-mentioned filtrate, plant ash water, and ground auxiliary materials at a weight ratio of 6:1:0.4, and let stand for 30 minutes to obtain Guanyin tofu.

Embodiment 2

[0049] The fresh leaves of Doufuchai picked in June with an unearthed height of 15 cm were mixed with water at a weight ratio of 1:5, beaten, and filtered to obtain a filtrate.

[0050] The plant material is dried to a moisture content of 30%, and then burned to obtain plant ash. The above plant ash and water were mixed at a weight ratio of 1:45, fermented at 10°C for 5 days, and the precipitate was removed to obtain plant ash water.

[0051] The auxiliary material is obtained by mixing fungus, kelp, lotus root, fish skin and stevia leaves in a weight ratio of 0.7:6:2:6:4. Chop the ingredients and grind them into a puree.

[0052] Mix the above filtrate and the auxiliary materials that are ground into mud at a weight ratio of 6:0.4, gelatinize at 50°C for 25 minutes, then stir with plant ash water for the first time at 10°C for 5 minutes, and then at 40°C Stir for the second time for 12 minutes. Stand still for 30min to obtain Guanyin tofu. The weight ratio of plant ash wa...

Embodiment 3

[0054] Take the fresh leaves of Doufuchai picked in July with an unearthed height of 20cm, mix them with water at a weight ratio of 1:10, make a pulp, and filter to obtain a filtrate.

[0055] The plant material is dried to a moisture content of 20%, and then burned to obtain plant ash. The above plant ash and water were mixed at a weight ratio of 1:55, fermented at 37°C for 3 days, and the precipitate was removed to obtain plant ash water.

[0056] The auxiliary material is obtained by mixing fungus, kelp, lotus root, fish skin and papaya paliurus leaves in a weight ratio of 1.2:9:3:10:4. Chop the ingredients and grind them into a puree.

[0057] Mix the above-mentioned filtrate and the auxiliary materials that are ground into mud at a weight ratio of 11:0.8, gelatinize at 50°C for 25 minutes, then stir with plant ash water for the first time at 10°C for 5 minutes, and then at 40°C Stir for the second time for 12 minutes. Stand still for 50min to obtain Guanyin tofu. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com