Mango Peeling Method

A mango and peel technology, applied in the field of mango peeling, can solve the problems of affecting the flavor and taste of mango pulp, low pulp yield, waste water pollution, etc., and achieve the effect of small flavor and taste, high pulp yield and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The invention provides a method for mango peeling, comprising:

[0055] Step 1. Place the mangoes graded according to size at 95°C for 10 minutes, remove them, and spray them with water to cool them down to room temperature;

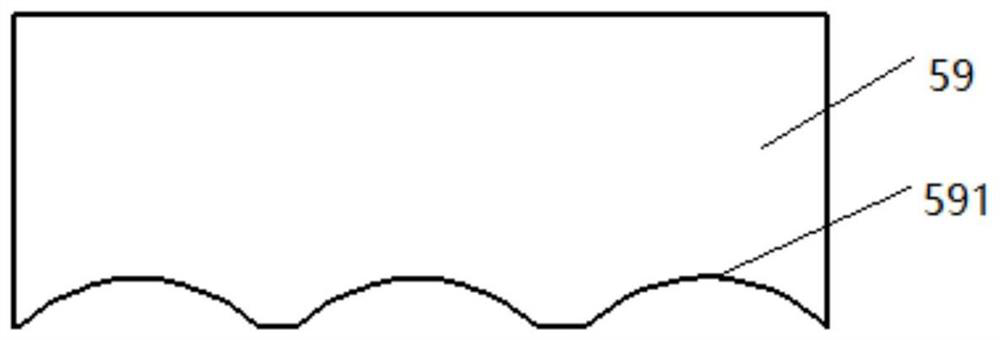

[0056] Step 2. Cut the mango peel along the longitudinal direction of the mango with a blade, and then cut it along the horizontal direction of the mango, so that the mango peel forms several independent small peel areas, and the area of each small peel area is not greater than 6cm 2 ;

[0057] Step 3: Put the mangoes into the enzymolysis solution for 30 minutes at 50°C, and remove them. The enzymolysis solution consists of the following raw materials in parts by weight: 1000 parts of water, 4 parts of pectinase, fiber 4 parts of prime enzyme and 1 part of papain;

[0058] Step 4. Place the mango under the spray water, and gently scrub with a brush to remove the peel;

[0059] Step 5. Put the collected pericarp into the waste enzymatic hydrol...

Embodiment 2

[0061] The invention provides a method for mango peeling, comprising:

[0062] Step 1. Place the mangoes graded according to size at 95°C for 12 minutes, remove them, and spray them with water to cool them down to room temperature;

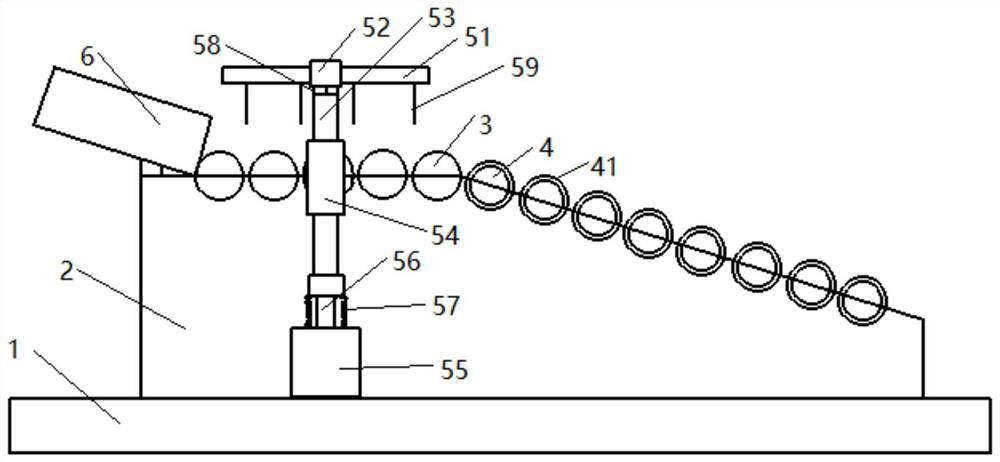

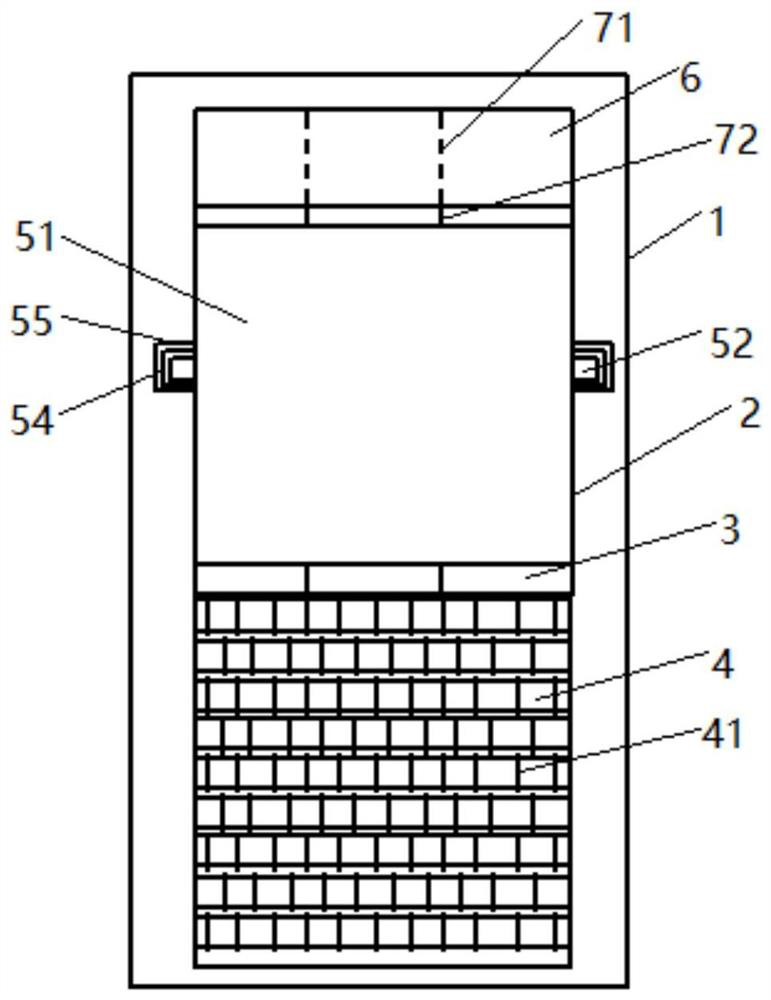

[0063] Step 2. Put the mango in the mango peeler, so that the mango peel forms several independent small peel areas, and the area of each small peel area is not greater than 4cm 2 ;

[0064] Step 3: Put the mangoes into the enzymolysis solution for 25 minutes at 50°C, and remove, wherein the enzymolysis solution consists of the following raw materials in parts by weight: 1000 parts of water, 4.5 parts of pectinase, fiber 4.5 parts of prime enzyme and 1.5 parts of papain, described mango peeling method, the enzyme activity of described pectinase is 100,000 u / g, the enzyme activity of described cellulase is 80,000 u / g, described The enzyme activity of papain is 800,000 u / g;

[0065] Step 4. Put the mango in the mango peeling machine, and remove...

Embodiment 3

[0068] The invention provides a method for mango peeling, comprising:

[0069] Step 1. Place the mangoes graded according to size at 95°C for 15 minutes, remove them, and spray them with water to cool them down to room temperature;

[0070] Step 2. Put the mango in the mango peeler, so that the mango peel forms several independent small peel areas, and the area of each small peel area is not greater than 4cm 2 ;

[0071] Step 3: Put the mangoes into the enzymolysis solution for 20 minutes at 50°C and remove, wherein the enzymolysis solution consists of the following raw materials in parts by weight: 1000 parts of water, 5 parts of pectinase, fiber 5 parts of prime enzyme and 2 parts of papain, the enzyme activity of the pectinase is 100,000 u / g, the enzyme activity of the cellulase is 80,000 u / g, and the enzyme activity of the papain is 800,000 u / g;

[0072] Step 4. Put the mango in the mango peeling machine, and remove the peel by spraying water and a brush;

[0073] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com